Required Air Stroke Valve Operating Times in Dynamic Supercharging

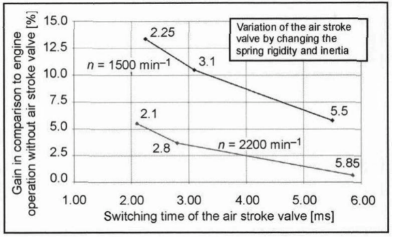

An extremely important variable in using air stroke valves for dynamic supercharging is the operating time of the air stroke valve system. Figure 10-92 shows the gain from actuating the air stroke valve twice per cycle in contrast to an induction pipe without an air stroke valve represented in measurements at different valve speeds.

The tests with different operating times were done by varying the moment of inertia and spring rigidity in the drive. This clearly illustrates that a fast valve with operating times of ∆ts = 2 ms is needed to realize the potential improvement. For example, the improvement from the air stroke valve at n = 1000 min-1 is cut in half when the operating time of the valve rises from ∆ts = 2.25 ms to ∆ts = 5.5 ms. At higher speeds, the improvement to the system falls almost to zero at operating times above ∆ts = 5 ms since dual actuation of the air stroke valve becomes increasingly useless to the charge cycle process.

Fig. 10-92. Gain in air expenditure as a function of the air stroke valve actuation time ΔtS with two cyles in the intake phase in a slow-running engine

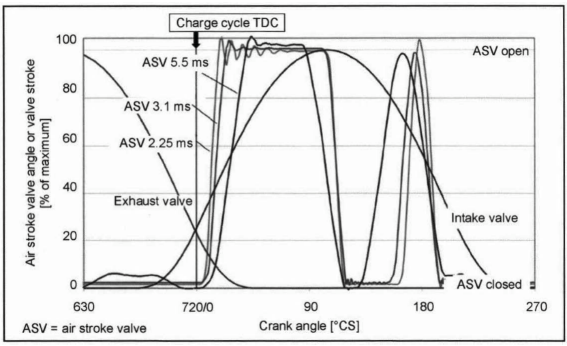

The explanation can be found by analyzing the operating times optimized for air expenditure with dual actuation of the air stroke valve at various valve operating times ∆ts that are listed in Fig. 10-93. One can see that the first air stroke valve starts to open at the same time in each case when the exhaust valve is nearly closed. The complete closure of the air stroke valve the second time is also the same in every case and occurs briefly after bottom dead center. A very short second opening time of the air stroke valve has a positive effect on air expenditure.

Fig. 10-93. Movement of the air stroke valve when varying the operating time ΔtS in a slow-running engine

Theoretically, the optimum opening time of the second cycle can be determined from the induction pipe and inlet port lengths. When the valve operating time is long, the second cycle becomes too long. The time remaining for the intake valve to open is then insufficient to have a positive effect.

When the air stroke valve has longer operating times, the opening must be complete much earlier in the first operating cycle, and the second operating cycle must begin immediately afterward. The inflowing air mass in the second operating cycle is thereby limited since a sufficient vacuum cannot build in the closing phase before the second opening. Furthermore, the backflow from the cylinder cannot be efficiently suppressed at the intake end when the air stroke valve operating times are long. The backflow occurs too quickly after the valve starts to open so that the air stroke valve cannot be reclosed at this time.

Date added: 2024-11-26; views: 309;