Additional Measures for Supercharged Internal Combustion Engines

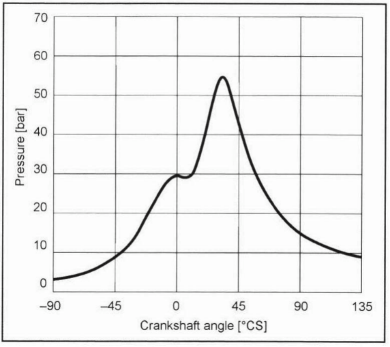

SI Engines. With the turbocharged SI engines, the higher charge pressure results in higher ultimate compression temperatures. This increases the risk of autoignition and of knocking. For this reason, it can be necessary to lower the compression ratio. In any case, the start of ignition of the SI engine must be shifted towards “retard” in order to avoid impermissibly high ignition pressures and knocking combustion (Fig. 11-43).

High exhaust gas recirculation rates increase the risk of knocking, particularly if an unfavorable exhaust pipe design exists in front of the turbine inlet.

Fig. 11-43. Pressure curve of a turbocharged SI engine with retarded ignition angle

In part-load operation, the mass flow of turbocharged SI engines is throttled by the throttle plate positioned downline of the compressor. The open-air circulation plate creates a bypass around the compressor so that the mass flow not required by the engine (part load) is returned in front of the compressor. As a result, no pressure is built up behind the compressor. This is also used for exhaust gas turbocharged SI engines, but is more important for mechanically supercharged engines because of the displacement characteristic of the turbocharger.

The turbine materials used today are high temperature steels (NiCr steels). With an exhaust gas temperature of T3 > 950°C, however, the strength drops sharply. Since the exhaust gas temperature of a turbocharged SI engine at full load can exceed 1000°C, the engine is enriched. This is performed in the engine controller using an additional control loop with exhaust gas temperature sensors. In the meantime, turbine materials are available that can withstand temperatures of up to 1050°C.

Diesel Engines. In diesel engines, the high charge pressure also results in very high ultimate compression pressures with compression ratios of ε > 14. Depending on the mechanical strength, the start of injection, therefore, has to be set very late in diesel engines so that under certain circumstances the compression pressure can be equal to or higher than the ignition pressure.

With medium-speed diesel engines, high charge pressures are used in conjunction with large valve overlaps (of up to 120° on the crankshaft) also to reduce the thermal load on the engine. The medium-speed engine is operated with high excess air factors (λ = 2).

With turbocharged diesel engines, the external exhaust gas recirculation demands additional measures in the form of a clocked control valve and software to control the charge pressure and the exhaust gas recirculation rate. Measures must also be taken to ensure that a negative scavenging gradient (p2 — p3) < 0 exists at all times.

Date added: 2024-11-26; views: 218;