Important Auxiliary Systems on Carburetors

Additional systems to the basic carburetor allow the carburetor to be used within the entire operating range of the engine with minimized emissions and fuel consumption as well as improved drivability. The following briefly lists the most important systems. It merely represents a selection; no claim is made for completeness.

(a) Acceleration enrichment. The preparation of the mixture that begins in the carburetor primarily occurs in the intake manifold. The boiling point of the fuel and the heating of the intake air and the intake manifold must be harmonized with each other to achieve the most homogeneous mixture in hot running engines. Yet even in hot running engines, high-boiling components of the fuel are still liquid in the intake manifold as film on the wall that is entrained by the air. The air enters the cylinder faster than the fuel. When the throttle valve is opened, the mixture becomes lean so that it must be temporarily enriched.

This is done by acceleration enrichment using an accelerator pump. Accelerator pumps are volume-displacing pumps with an intake and pressure valve. In the intake stroke, fuel streams from the float chamber through the intake valve into the pump interior. Upon the delivery stroke, fuel is generally delivered by the pressure valve to an injection device. This is calibrated and leads into the intake air duct. The delivery stroke is executed by a pump spring that is pretensioned in various ways.

A distinction is drawn between

- Mechanically actuated plunger pump (Fig. 12-3)

- Mechanically actuated diaphragm pump

- Pneumatically actuated accelerator pump

Fig. 12-3. Carburetor with mechanically actuated accelerator pump

(b) Actuating and constructing a second carburetor stage. In multistage carburetors, there are several systems for actuating the second stage with similar constructions. It is important for the second stage to always be reliably closed with the first stage.

A distinction is drawn between mechanically and pneumatically actuated systems.

Mechanically actuated second stage: In mechanically actuated systems, the second carburetor stage is primarily actuated by a trailing linkage. The opening is frequently restricted to prevent a temporary lean mixture.

The second stage frequently opens only when the first stage is already half open, and a catch of the throttle control lever is correspondingly positioned. Both valves reach the full opening position simultaneously. The design of the second stage largely corresponds to that of the first stage: There is a main system and transition system similar to the idling system in the first stage with a large fuel reserve. The transition system should ensure a smooth torque increase when the second stage opens quickly at low rpm with a correspondingly high pressure in the intake manifold.

For carburetors whose second stage is a constant pressure stage, the throttle valves on a common shaft actuate the second stage with a trailing linkage.

Pneumatically actuated second stage: In this design, both stages are constructed as fixed air funnel carburetors. A diaphragm unit actuates the second stage with a connecting rod articulated to the throttle control lever of the second stage. A corresponding design ensures that the second stage can open only when the first is almost completely open, and the second is closed with the first stage.

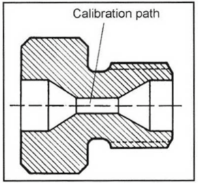

(c) Nozzles. These meter fuel, compensating air, and the premixture. To form an optimum flow and protect the actual calibrating section, they have an inlet cone and sometimes an outlet cone. Figure 12-4 shows a typical main nozzle. They can be used in both flow directions.

Fig. 12-4. Nozzle with a calibration section

(d) Float chamber. A float chamber serves to control the fuel level in the carburetor, functions as a fuel accumulator, and contains a guided float that immerses in the fuel. The float actuates a needle, thus closing the body of the float needle valve that blocks the inflow of fuel when a set level has been attained.

There are carburetor designs that do not control the fuel level with a float chamber. The level in the fuel accumulator is controlled by means of the pressure in the fuel accumulator (diaphragm carburetor).

In order to work, the float chambers must be ventilated. A distinction is drawn between external and internal ventilation. With external ventilation, the gas area of the float chamber is directly connected to the environment surrounding the carburetor. This prevents problems when the engine is running hot that could arise from the fuel evaporating out of the float chamber.

With internal ventilation, a pipe leads into the inlet or pure air side of the air filter.

(e) Starting controls. In carburetor engines, special attention must be given to controlling the engine from a cold start through warm-up to a “hot” engine. In particular, the legal limits for exhaust emissions, problems associated with mixture distribution, fuel deposits on the wall, costs, and operating and driving comfort are requirements that must be taken into account.

The requirements, in particular, the enrichment of the mixture, result from

- Increased friction from unattained operating temperature

- Insufficient mixture preparation

- Increased power demand for auxiliary systems

In a stoichiometric mixture of air and conventional fuel (boiling curve), the dew point under environmental pressure is approximately 35°C. The homogenization of the mixture can generally happen only in the cylinder when the dew point temperature of the mixture in the cylinder is exceeded during the compression stroke. Consequently, there is always a large amount of liquid fuel in the intake system in cold engines. The mixture must, therefore, be enriched in comparison to a warm operating state even when the engine is idling to compensate for deficient homogenization. In addition, the fuel must be enriched during acceleration. The amount of enrichment must be greater as the air and intake manifold wall temperature decreases. The main reference variable for enrichment is the temperature of the intake manifold.

The mixture formation is adapted to the following phases:

- Initial poststart phase. The engine starts as soon as there is an ignitable mixture. This process occurs faster at high temperatures than at low temperatures. In addition, a stationary mixture enrichment is required depending on the initial temperature and the time after the start

- Run-up to a stable idling speed. An initial, very strong enrichment must be attenuated for the mixture to remain flammable

- Warm-up to operating temperature. The mixture stream and the enriching can be adjusted depending on the temperature of the intake manifold corresponding to the engine heat.

- There are three basic systems for controlling starting: The manual starter, which is not discussed here since it is defunct.

- Automatic choke (Fig. 12-5). The mixture stream for starting and idling the cold engine is ensured by opening the throttle valve; the mixture is enriched with the choke. The temperature-dependent control element is a bimetal spring against which a choke can be drawn by the air stream. The functional relationship between the position of the choke and the position of the throttle valve is established by a cone pulley. In contrast to a fully automatic start, the functional process before the start must be triggered by a single depression of the gas pedal. The bimetal spring is heated to raise its temperature to that of the engine. As the temperature of the bimetal spring rises, the choke opens, and mixture enrichment is attenuated.

Fig. 12-5. Automatic chokes

- Fully automatic start. The essential difference from an automatic choke is that this system is not triggered before starting. The control of the fuel mixture stream for idling a cold engine is separate from the mixture enrichment, depending on the inducted air stream

There are whole series of devices and additional functions for carburetors that improve their operating behavior such as the throttle valve actuator, pressure tapping holes, systems for compensating air, idling transition, additional mixture, and circulating air, to name only a few, which, however, are not discussed here.

Date added: 2024-11-26; views: 355;