Electronically Controlled Carburetors

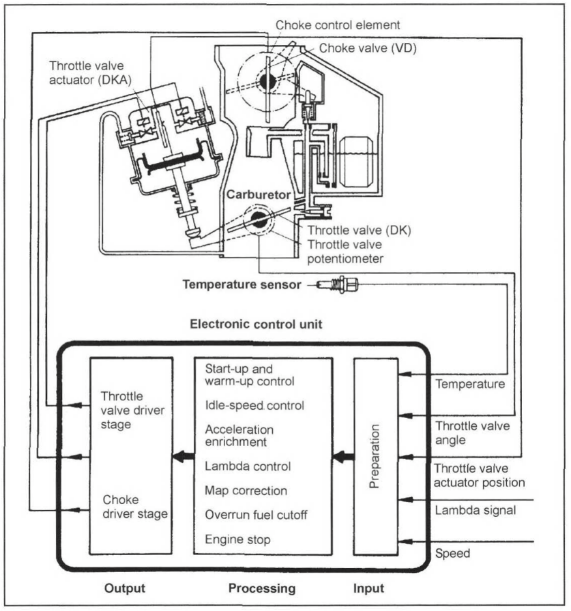

Electronically controlled carburetors were developed to improve the adaptation of the mixture to all engine operating ranges and, hence, meet the demands for minimizing untreated emissions and lowering fuel consumption. A lambda closed-loop control was later adapted to the system. The mechanical design of the electronically controlled carburetor is basically identical to conventional carburetors. Additional features are the following: the throttle valve is actuated in the near-idling range, the mixture enrichment is influenced, and there are additional sensors and an electronic control unit (Fig. 12-6).

Fig. 12-6. Block diagram of an electronically controlled carburetor

The electronically controlled carburetor is basically a fixed air funnel carburetor with a two-stage design with a pneumatically actuated second stage. The throttle valve for the first stage is actuated in the range close to idling with a continuously variable, position-regulated throttle valve actuator.

The continuously variable mixture enrichment over the entire range is carried out by means of the choke in the first stage that is actuated to restrict the air flow to enrich the mixture.

On the throttle valve shaft of the first stage is a throttle valve potentiometer that determines the throttle valve position or the change of the throttle valve position. Signals from the sensors consisting of the temperature sensor for the coolant and intake manifold, the idle switch on the throttle valve actuator and a speed tap are input variables for the electronic control that moves the throttle valve of the first stage as well as the choke.

The following functions exist:

- Control of engine start and warm-up

- Acceleration enrichment

- Lambda closed-loop control

- Influence of the air-fuel ratio in the program map

- Idling speed control

- Overrun fuel cutoff

- Catalytic-converter protection function by shutting off the fuel

When starting with an electronic carburetor, the throttle valve of the first stage is actuated, and the choke is fully closed. During the run-up phase, the idling speed control takes over the control of the throttle valve with a set point depending on the coolant temperature of the engine. The mixture enrichment is controlled with the choke, and a basic enrichment is dictated as a function of the intake manifold temperature in the program map while stationary. This is added to acceleration enrichment when the load of the engine increases.

Date added: 2024-11-26; views: 37;