Systems for Direct Injection

In addition to the described possibility of injecting liquid fuel into the intake manifold of the spark-ignition engine, direct injection systems have been developed in recent years. The fuel is directly injected into the combustion chamber from a central fuel rail under high pressure by electronically controlled fuel injectors (the common rail principle).

By layering the fuel and air by injecting during the compression phase, a relatively lean mixture is produced with a relatively rich mixture cloud close to the spark plug that ensures reliable ignition. Because of the excess air in this mode of operation, there is a reduction in the charge cycle work and in the loss of wall heat during the high- pressure phase of combustion, which together substantially lowers the specific fuel consumption.

In addition, the direct injection cools the interior of the cylinder from the evaporation of the fuel that reduces knocking at full loads. This makes it possible to increase the compression by approximately one unit. The specific fuel consumption is also lowered. Stratified operation makes sense only within a limited range of operation under a partial load in a spark-ignition engine. In other ranges, the engine is operated homogeneously lean, stoichiometrically, or rich under a full load.

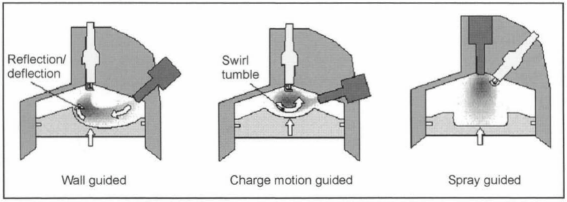

Depending on the installation site and position of the fuel injector and the arrangement of the air intake into the cylinder, a distinction is drawn between wall-directed, air- directed, and jet-directed combustion (Fig. 12-11):

Fig. 12-11. Combustion

- High-pressure direct injection (HPDI) with wall-directed combustion (Fig. 12-11, left):

The fuel injector is on the side, and the fuel is sprayed onto the piston head. With the shape of the piston recess and the type of airflow, the injected fuel is directed toward the spark plug.

Depending on the geometry of the intake ducts where the air streams in, a distinction is drawn between a reverse tumble procedure and a HPDI with air-directed combustion.

- HPDI with air-directed combustion (Fig. 12-11, middle):

The fuel injector is also located on the side, but the fuel is injected into the air in the center of the combustion chamber in contrast to wall-directed combustion. A substantial amount of air movement is necessary, which is generated by a variable tumble.

- HPDI with jet-directed combustion (Fig. 12-11, right):

This type of combustion has the greatest potential for lean engine operation and, hence, the greatest potential savings in fuel consumption—more than 30% at a low partial load. The fuel injector is located in the center of the combustion chamber, and the spark plug is close to it at a lateral angle. This prevents the fuel from contacting the piston or combustion chamber walls. This type of combustion places large demands on the preparation of the jet by the fuel injector. To ensure reliable ignition and low fouling of the spark plug, the fuel in the area of the spark plug must be finely atomized, and the spray pattern may not change substantially when the combustion chamber pressure changes.

In addition, there exists air-supported direct injection (OCPTM—“orbital combustions system” which is a registered trademark of Orbital Corporation) in which the central injector position close to the spark plug has proven to be particularly advantageous.

The overall lean mixture during combustion in stratified operation creates a problem for exhaust aftertreatment: Conventional three-way catalytic converters cannot reduce NOx emissions. Despite lower untreated NOx emissions from exhaust gas recycling rates of up to 30%, untreated NOx emissions must undergo special aftertreatment to meet the exhaust thresholds. Beyond selective NOx reduction catalysts that have a low thermal stability, so-called NOx storage catalytic converters are used. Storage catalytic converters absorb the NOx emissions in lean operation and convert them in substoichiometric operation into N2 and C02. A complex engine management function controls this process. Storage catalytic converters tend to experience “sulfur poisoning” and, therefore, require fuels with low sulfur content.

The exhaust aftertreatment measures reduce the savings in effective fuel consumption that result from direct injection.

Date added: 2024-11-26; views: 355;