Multilocational Production. Plant-Closure Decisions

Declining demands for industrial products can induce multilocational firms to retrench their operations. Many respond to economic declines by closing one or more plants. In the United States alone, over 2 million workers lost their jobs as a result of multilocational plant closures between 1979 and 1984. Indeed, the closure of branch plants has been the single largest cause of job loss in the United States for nearly two decades.

The effects of plant closure on the host community can be devastating. When a plant is closed and workers lose their jobs, other local businesses suffer. Laid-off employees have less income available to spend on local goods and services. The community's tax base declines as sales decrease and property values are lowered. Many employees move away and. as they do so. the community's need for education, medical care, entertainment, and other services declines correspondingly. The concept of the multiplier effect, measures the overall impact on a local economy of a projected or actual plant closure. The decision of which plant to close is not necessarily straightforward.

Older plants that rely on antiquated or obsolete equipment may be candidates for shutdown. Those that specialize in the manufacturing of products no longer in demand by consumers are also likely candidates. In some cases, however, a firm must choose candidates for closure among plants that produce the same product with equally up-to-date technology.

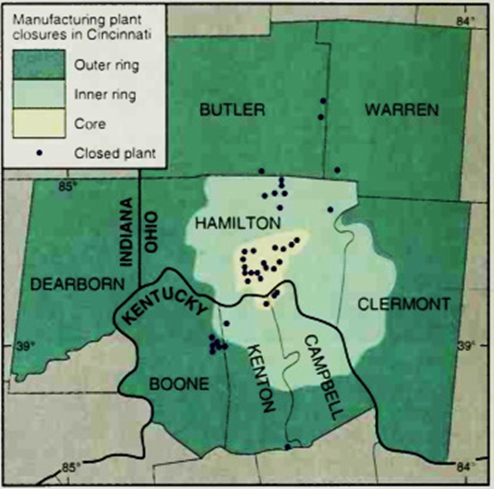

The geography of plant closures in the Cincinnati. Ohio, area was the focus of a recent study (Figure 8-11). In this metropolitan area of approximately 1.7 million people, about 173,000 workers (approximately 28 percent of the civilian labor force) were employed in manufacturing. These workers were distributed among over 2.300 firms, of which 524 employed 50 or more people. Between 1980 and 1988. 39 plants in the Cincinnati area shut down. About 13,000 jobs were lost as a result of these closures. Twenty-two of the 39 cases involved a decision as to which of two or more similar plants in different locations should be closed.

Figure 8-11 Plant Closures in Cincinnati. A recent study of plant closures in the Cincinnati metropolitan area indicated that closures tended to be concentrated in old industrial areas rather than suburban locations. In some cases, age and technological obsolescence influenced closure decisions: in others, plants were closed for labor-related reasons

Interviews with firm executives revealed that the age and size of the plant made little difference in many of their closure decisions. Other plant characteristics, such as relative technological sophistication, flexibility to adapt to new product lines, and space for expansion, were frequently cited as factors, however. These characteristics were often more important than the specific plant location. Yet firm executives often expressed concern with labor-related costs in making plant-closure decisions. Those plants located in areas where labor costs were high or labor-management conflict was considerable tended to be targeted for closure.

Labor cost as a factor in plant-closure decisions becomes even more critical as geographic scales increase. General Motors announced the impending closure of several assembly plants in the spring of 1992. All of the affected plants were located in the Great Lakes states and in neighboring Ontario. By contrast, General Motors officials kept their Arlington, Texas, plant open. That the Arlington plant remained open was attributed to the fact that its employees had previously agreed to accept wage cuts, whereas higher paid employees in the Great Lakes states had continued to work at the same wage levels.

Date added: 2024-03-15; views: 756;