Toughened (Tempered) Glass. Laminated Glass

Toughened safety glass is a pre-stressed glass. Pre-stressing is achieved by thermal treatment. The production method consists of rapid heating followed by rapid cooling with a blast of cold air. In comparison to float glass, which produces sharp, dagger-like glass splinters when broken, this glass breaks into small, mostly round-edged glass crumbs. The danger of injury is thus greatly reduced.

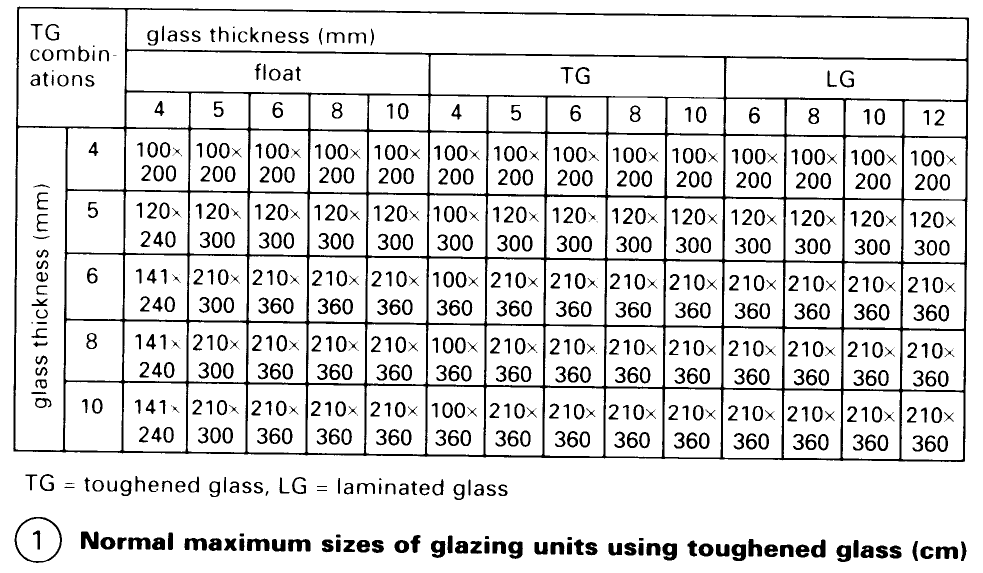

Toughened glass has the further advantages of increased bending and impact-resistant qualities and tolerance to temperature change (150K temperature difference, and up to 300°C compared with 40°C for annealed material. It is also unaffected by sub-zero temperatures). Toughened glass also has enhanced mechanical strength (up to five times stronger than ordinary glass), so it can be used in structural glazing systems. Alterations to, and work on, toughened glass is not possible after production. Even slight damage to the surface results in destruction. However, tempered safety glass can be used in conventional double-glazing units – (1).

Areas of use: sports buildings (ball impact resistant); school and playschool buildings because of safety considerations; living and administration buildings for stairways, doors and partitions; near radiators to avoid thermal cracking; for fully glazed fagades, and elements such as glazed parapets and balustrades on balconies and staircases to prevent falls.

Laminated glass. During the manufacture of laminated glass, two or more panes of float glass are firmly bonded together with one or more highly elastic polyvinylbutyral (PVB) films. Alternatively, resin can be poured between two sheets of glass which are separated by spacers, and the resin is then cured. This process is called cast-in-place (CIP). The normal transparency of the glass may be slightly reduced depending on the thickness of the glass. Laminated glass is a non-splintering glass as the plastic film(s) hold the fragments of glass in place when the glass is broken, thus reducing the possibility of personal injury to a minimum.

There are several categories of laminated glass: safety glass, anti-bandit glass, bullet-resistant glass, fire-resistant glass and sound-control glass. The thickness and the number of layers of glass, and the types of interlayer, are designed to produce the required properties.

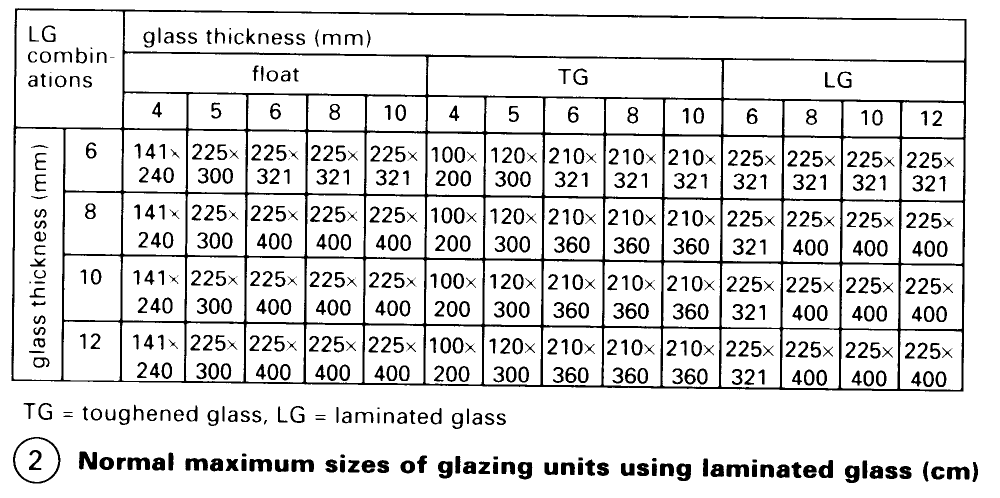

Laminated safety glass. Laminated safety glass normally consists of two layers of glass bonded with polyvinylbutyral (PVB) foil. This is a standard product which is used to promote safety in areas where human contact and potential breakage are likely. The tear-resistant foil makes it difficult to penetrate the glass, thus giving enhanced security against breakage and breakin. Even when safety glass is broken, the security of the room is maintained. Laminated safety glass is always used for overhead glazing for safety and security reasons - (2). Building regulations insist on its use in certain situations.

Areas of use: glazed doors and patio doors; door sidelights; shops; all low-level glazing; balustrades; bathing and shower screens; anywhere that children play and may fall against the glass, or where there is a high traffic volume, e.g. entrance areas in community buildings, schools and playschools.

Laminated anti-bandit glass. Laminated anti-bandit glass is the most suitable material for providing complete security in protective glazing systems. Anti-bandit glass can be made with two glass layers of different thicknesses bonded with PVB foil, or with three or more glass layers of different glass thicknesses bonded with standard or reinforced PVB foil. Additional security can be provided by incorporating alarm bands, or wires connected to an alarm system.

One side of this glass will withstand repeated blows from heavy implements such as bricks, hammers, crowbars, pickaxes etc. There may be crazing in the area of impact, but the tough, resilient PVB interlayers absorb the shock waves, stop any collapse of the pane and prevent loose, flying fragments of glass. Even after a sustained attack, the glass continues to provide visibility and reassurance, as well as protection from the elements. Additional security can be achieved by bonding the glass to the framing members so that the frame and the glass cannot be separated during an attack. Normally, the side of the expected attack is the external side. Only in law courts should the side of the expected attack be on the inside. It is not permissible to change the orientation of the glazing without good reason.

Areas of use: shops; display cases; museums; kiosks and ticket offices; banks; post offices; building societies; wages and rent offices; etc.

Date added: 2023-01-01; views: 640;