Extinguisher Systems. Sprinkler Systems. Extinguisher Water Pipelines

Sprinkler systems. Wet sprinkler systems are systems in which the pipeline network behind the wet alarm valve station is permanently filled with water. When a sprinkler responds, water emerges from it immediately.

In dry sprinkler systems, on the other hand, the pipeline network behind the dry sprinkler valve station is filled with compressed air, which prevents water from flowing into the sprinkler network. When the sprinkler system is triggered, the retaining air pressure is released and water flows to the sprinkler heads. Dry sprinkler systems are used where there is a risk of frost damage to the pipework.

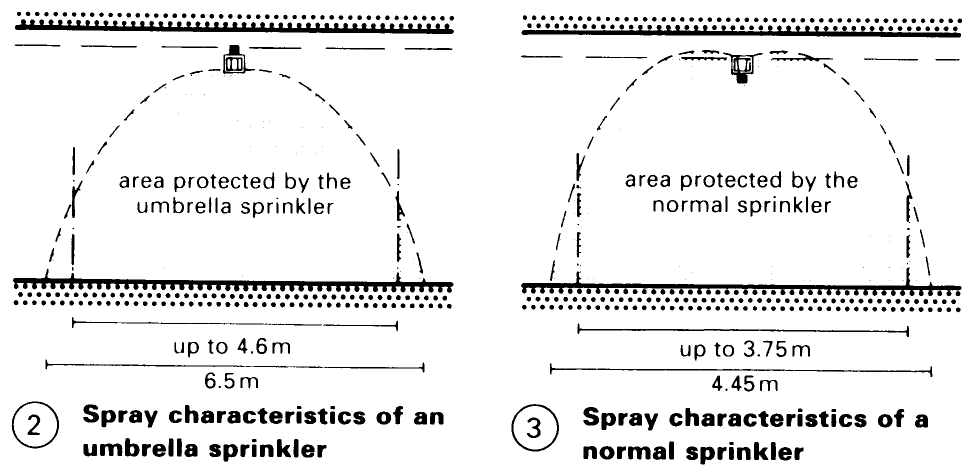

Normal sprinklers deliver a spherical water distribution towards the ceiling and the floor whereas the water from umbrella sprinklers falls in a parabolic pattern towards the floor. Both kinds can take the form of self-supporting or hanging devices. - (2) + (3).

Automatic fire extinguisher systems commonly employ fixed pipelines to which closed nozzles (sprinklers) are connected at regular intervals. When the system is activated, water is released only from those sprinklers where the sealing devices have reached the set response temperatures required to open them. These types of arrangements are also known as selectively operated extinguishing systems.

Sprinkler distribution. A choice can be made between a normal or staggered distribution of sprinklers but where a staggered distribution is proposed the sprinklers should be arranged in as uniform a way as possible.

Spacing between sprinklers; distance from walls and ceilings. The spacing between sprinklers must be at least 1.5m. The maximum spacing is determined as a function of the area the sprinkler is protecting, the distribution of the sprinklers and the fire hazard. This rule does not apply to sprinklers in stacking systems.

The permissible spacing between sprinklers and flat ceilings/roofs varies according to the type of sprinkler and the flammability of the inside of the ceiling or roof. It also depends on the insulating layer of profiled cladding roofs. For trapezoidal section cladding roofs, the minimum spacing of the sprinkler from the ceiling is measured from the lowest point of the corrugation and the maximum spacing is measured from the mean point between the lowest and highest points of the corrugations.

Spacing of sprinklers relative to supporting beams or other structural components. If supporting beams, joists or other obstructions (e.g. air conditioning ducts) run below the ceiling, then the minimum spacings must be maintained between these components and the sprinklers. The exceptions here are side wall sprinklers, installation of which is only permitted for flat ceilings.

Open nozzle systems. Systems with open nozzles are water distribution systems with fixed pipelines, to which open nozzles are attached at regular intervals. When on standby, the pipe network is not filled with water. When the system is activated, the peak flow pressure passes immediately from the water supply into the network of pipes and nozzles.

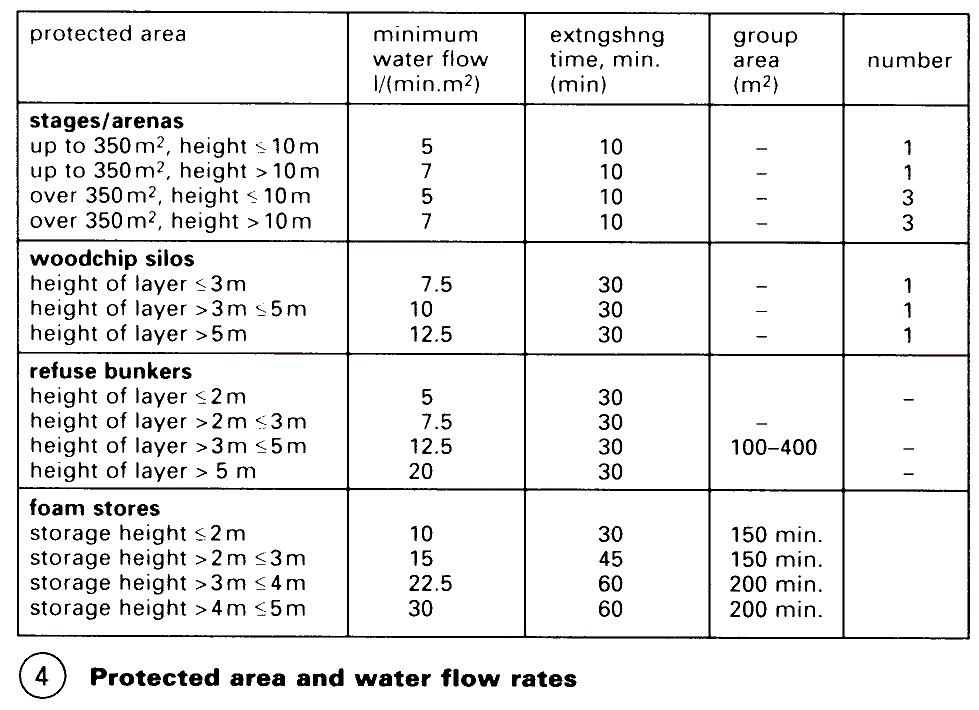

The water pressure is directed according to the size and shape of the room which is to be protected and the type and quantity of the contents. Depending on the height and type of storage facility, and any wind effects, the system must deliver between 5 and 60 litres per minute per square metre – (4). For room protection systems which are subdivided into groups, the area protected by a group should generally lie between 100m2 (high fire risk) and 400m2 (low fire risk).

Water spray extinguisher systems are used, for example, in aircraft hangars, refuse bunkers and incinerator facilities, arenas, facilities for containers and combustible fluids, cable ducting, chipwood silos and factories, power stations, and factories making fireworks or munitions.

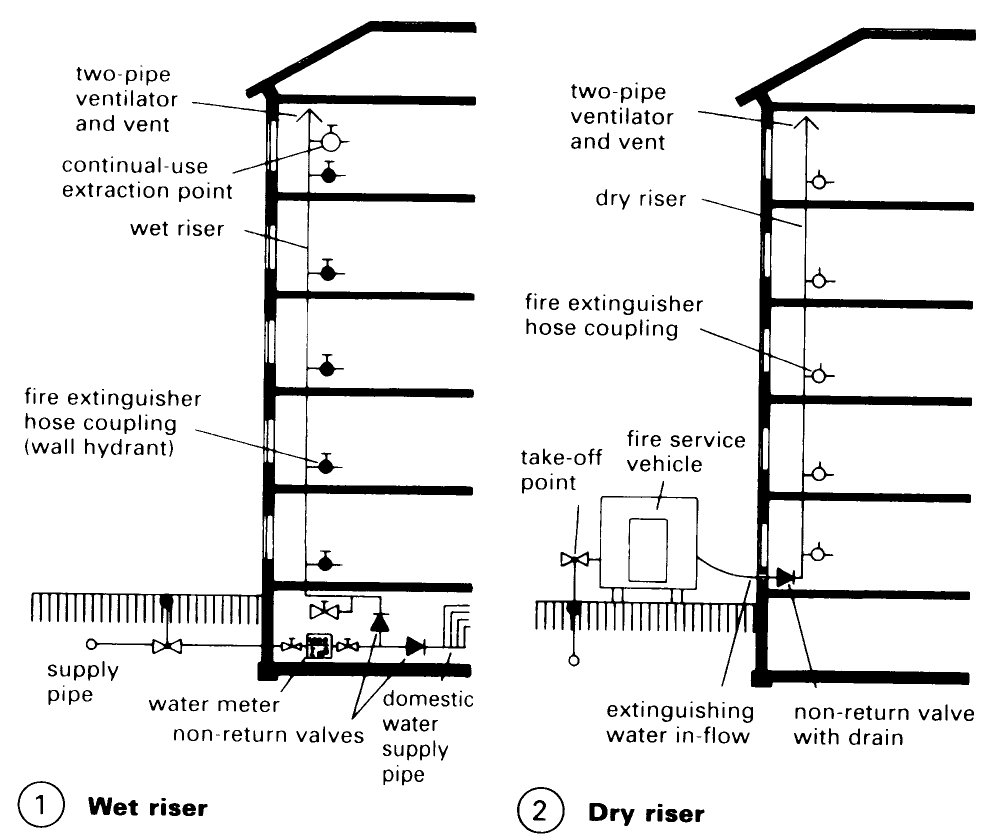

Extinguisher water pipelines. Extinguisher water pipelines are fixed pipes in structures. They make available the water supply for fire extinguisher hoses, which are connected by valve couplings that can be closed. There are two main types: (1) wet risers, which are extinguisher water pipelines that are continually under pressure, and (2) dry risers, which are pipelines to which extinguisher water is supplied by the fire service when it is required. Wet/dry risers are extinguisher water pipelines which, on the remote activation of valves, are supplied with mains water when required.

The following are typical nominal pipe bore sizes for extinguisher pipes and wall hydrants:

- where there are two interconnected access points: 50mm minimum

- where there are three interconnected access points: 65mm minimum

- where there are four or more interconnected access points: 80mm minimum.

With wet risers, wall hydrants can be accommodated in built-in recesses or in wall cavities. The lower edge of the wall hydrant should be between 800 and 1000mm above floor level.

Dry risers have a nominal diameter of 80mm and have a drainage facility. The couplings of the supply valve should be 800mm above the surface level of the surroundings and the hose connector valve should be 1200mm above floor level.

C02 Fire Extinguisher Systems. Powder Extinguisher Systems. C02 Fire Extinguisher Systems. Carbon dioxide works as an extinguishant by reducing the oxygen content in the air to a value at which the burning process can no longer be sustained. Being gaseous, it can flood the threatened area rapidly and uniformly to provide very effective protection.

C02 is suitable for extinguishing systems in buildings containing the following substances and installations:

- flammable fluids and other substances that react as flammable fluids when burning

- flammable gases, provided that precautions are taken to ensure that following successful extinguishing, no combustible gas/air mixture forms

- electrical and electronic equipment

- flammable solids susceptible to water damage, such as paper and textiles, although fires involving these materials require high concentrations of C02 and prolonged exposure to put them out.

Fixed C02 systems are frequently used in areas given over to:

- machines that contain flammable fluids, or in which such fluids are used

- paint manufacture, spray painting, printing, rolling mills, electrical switch rooms and data processing rooms.

Typically, where these systems are to be used for the protection of rooms, one nozzle must not safeguard an area greater than 30 m2. Where rooms are over 5m high, the nozzles used for general spraying of C02 must not only be installed in the upper portion of the room, under the ceiling, but also at a level approximately equal to one third of the room height.

The function of C02 systems is to extinguish fires during the initial phase and to maintain a high C02 concentration until the danger of re-ignition has abated. These systems consist essentially of C02 containers, back-up supplies of extinguishant, the necessary valves and a fixed pipe network with a suitable distribution of open nozzles and devices for fire detection, activation, alarm and extinguisher operation.

Powder extinguisher systems. Extinguishing powders are homogeneous mixtures of chemicals that act as fire suppressants. Their base constituents are, for example, as follows:

- sodium/potassium bicarbonate

- potassium sulphate

- potassium/sodium chloride

- ammonium phosphate/sulphate.

Since the powder is ready for use under normal conditions at temperatures of -20°C to +60°C, it is used for buildings, in closed rooms and also for outdoor industrial applications. Powder extinguishants are suitable, for example, where the following substances and installations are involved:

- solid flammable substances such as wood, paper and textiles, where a suitable powder is required in all cases

- flammable fluids and other substances which, when burning, react as flammable fluids

- flammable gases

- flammable metals, such as aluminium, magnesium and their alloys, for which only special extinguishant powders are employed.

Examples of industrial areas where fixed powder systems are frequently used include chemical plant and associated process plant, underground oil storage facilities, filling stations, compressor and pumping stations, and transfer stations for oil and gas. There are also some installations in which powder extinguishants should not be used. These include areas housing, for example:

- dust sensitive equipment and low-voltage electrical installations (e.g. telephone systems, information processing facilities, measurement and control facilities, distribution boxes with fuses and relays, etc.)

- materials which are chemically incompatible with the extinguishant (i.e. there is the danger of chemical reaction).

Halon room protection systems. Halon is a halogenated hydrocarbon, usually bromotri- fluoromethane. Its extinguishing effect is based on the principle that it supresses the reaction between the burning material and oxygen. Halon systems can only be used in extinguishing areas where the room temperature will remain between -20°C and +450°C and neither should there be any equipment with an operating temperature above 450°C in the extinguishing area.

Halon 1301, for example, is suitable for fires in areas containing:

- fluids and other substances that react as flammable fluids when burning

- gases, provided that no combustible gas/air mixture can form after the fire has been extinguished

- electrical and electronic equipment and plant.

Examples of activities and areas for which halon systems are suitable include:

- paint manufacture, spray paint shops, powder coating plant

- electrical equipment rooms

- electronic data processing and archiving rooms.

The possibility of environmental damage cannot be excluded and should be considered where halon systems are proposed.

Foam extinguishing systems. Foam systems are used for extinguishing fires in buildings, rooms and outdoors, and they can also be used to form a protective layer over flammable liquids. The foam extinguishant is generated through the action of a water/foaming agent mixture with air. The foaming agents are liquid additives that consist of water-soluble products of protein synthesis and, if required, may contain additional fluorinated active ingredients.

The key characteristics of foam extinguisher systems to be considered are the water application rate, the requisite amount of foaming agent and the minimum operating time (e.g. between 60 and 120 minutes, depending on the type of foam). The system should be sized so that, in the event of a fire, sufficient foam enters the protected area to provide an effective cover. Precautions must be taken to prevent the escape of flammable fluids from the protected area (e.g. upstands). Account must also be taken of flow and spraying distances, possible obstructions, and the spacing and type of objects to be protected.

Date added: 2023-01-01; views: 713;