Multicriteria Decision Making Approach

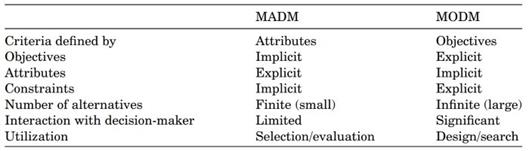

MCDM addresses the problem of making decisions in the presence of multiple, usually conflicting criteria. MCDM includes two main fields, namely multiattribute decision making (MADM) and multi-objective decision making (MODM). While MADM refers to making preference decisions over a finite number of alternatives, considering multiple and possibly conflicting attributes, MODM aims to design the best alternative given a set of multiple and conflicting objectives.

MCDM techniques are applied when a selection/design problem with multiple and usually conflicting attributes/objectives with incommensurable units is encountered. Conflict among attributes/objectives increases in the sense that a favorable value in one may have to be obtained with a poor value in the other. Incommensurable units refer to each criterion that has different units of measurement rendering a direct comparison between different criteria impossible. The basic differences in MADM and MODM problems are provided in Table 1.

Table 1. Comparison of MADM and MODM Approaches

Because the decision problem addressed here considers selection among a finite number of alternatives, in the presence of multiple and conflicting attributes with each attribute having different units of measurement, a MADM approach would be required.

In this section, a decision-making approach that integrates quality function deployment and fuzzy linear regression is presented to address the robot selection problem. The delineated procedure is based on the methodology developed by Karsak (2). QFD is a customer-oriented design tool that aims to meet customer requirements in a better way and enhance organizational capabilities while maximizing company goals.

A key objective of QFD is to determine directly from the customer what they would expect from a specific product or service. QFD aims at delivering value by focusing on prioritized customer requirements, translating these into engineering characteristics (design requirements), and then communicating them throughout the organization in a way to assure that details can be quantified and controlled.

Relationships between customer requirements and engineering characteristics and among the engineering characteristics are defined by answering a specific question that corresponds to each cell in a matrix named the house of quality (HOQ). Hauser and Clausing (26) defined the HOQ as a kind of conceptual map that provides the means for interfunctional planning and communications.

Fuzzy linear regression was first introduced by Tanaka et al. (27). As opposed to statistical regression that is based on probability theory, fuzzy regression is founded on possibility theory and fuzzy set theory. In fuzzy regression, regression residuals that denote the deviations between observed values and estimated values are assumed to be caused by imprecise and vague nature of the system. Fuzzy regression has been reported as a more effective tool than statistical regression when the data set is insufficient to support statistical regression, human judgments are involved, and the degree of system fuzziness is high (27).

Fuzzy linear regression is selected as a decision tool for parameter estimation of functional relationships because of its aptness to deal with human expert knowledge, which is an important source in robot selection. First, the ratings for factors such as product quality, manufacturing flexibility, and vendor support that are listed among customer requirements are generally represented by expert judgment.

Moreover, the fuzziness inherent in the relationships between customer requirements and robot characteristics, and the dependencies among robot’s technical characteristics (i.e., the relationships between performance parameters, such as repeatability, velocity, and load capacity, which are difficult, if possible, to determine precisely) can be expressed effectively using expert judgment.

Over the past decade, some research has been performed on quantifying the planning issues in HOQ, mainly focusing on the interpretation of imprecise design information related to customer requirements and relationships between customer requirements and engineering characteristics. Many authors have used fuzzy set theory to consider the imprecision and vagueness in determining the importance of customer requirements and addressing the relationships between customer requirements and engineering characteristics.

Few researchers have addressed the development of procedures for setting target levels for engineering characteristics using fuzzy regression and fuzzy optimization. Chan and Wu presented a comprehensive review of QFD including quantitative methods applicable to it.

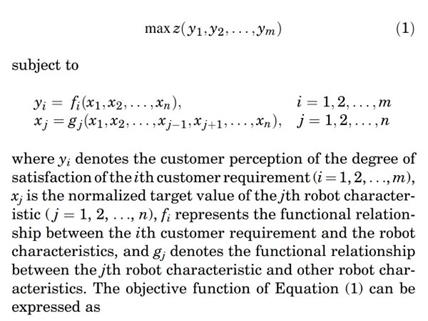

Similar to the process of setting target levels for engineering characteristics in QFD, the target values for the robot characteristics can be determined by solving the following formulation:

The information provided in the HOQ can be used to estimate the parameters of the functional relationships fi and gi. Because the relationships between customer requirements and robot characteristics and the interactions among robot characteristics are vague and generally difficult to define precisely, fuzzy regression seems to be a sound alternative approach for serving this purpose.

A fuzzy linear regression model is defined as follows:

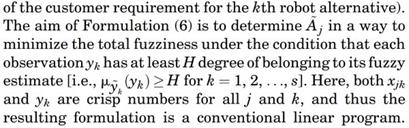

When no fuzziness is considered in the system parameters, only the center value estimates obtained from Formulation (6) are used in Formulation (3), whereas the spreads are ignored. Applications of fuzzy linear regression to QFD have been reported in the literature.

Date added: 2024-02-23; views: 545;