Exhaust Systems. Designs. Overall System

The exhaust system fulfills three tasks. It influences the power characteristic of the engine, it reduces exhaust noise, and it reduces the pollutants in the exhaust together with an installed catalyst. These tasks cannot be fully separated from each other. The noise damping always influences the power characteristic, generally in an undesirable manner; conversely, maximum performance exhaust systems are often too loud. The sound pressure at the exhaust valve lies between approximately 60 and 150 dB (A). This needs to be reduced to the legally prescribed value (Fig. 10-39).

Fig. 10-39. Decrease of gas-column vibrations in mufflers

Similar to the processes at the fresh gas side of a reciprocating piston engine, transient flow behavior is also found in the exhaust system. When the exhaust valve is opened because of the overpressure in the cylinder, and later by the upwards-moving piston, an overpressure wave is induced that continues toward the tailpipe. Pressure and speed waves are reflected at the open pipe ends and are returned as an aspiration wave. This supports the charge cycle by lowering the exhaust counterpressure when the pipe lengths in the exhaust system are dimensioned correctly. Contrastingly, a returning overpressure wave can hinder the exit of fresh gas that is already in the cylinder. This mechanism is primarily exploited during the operation of two-stroke engines.

Designs. There are two basic muffler designs: The resonator-type muffler and the absorption-type muffler. Frequently, combinations of the two types are used (Fig. 10-40), which reduce noise within the relevant range of 50 to 8000 Hz. Depending on the engine design (displacement, output, supercharging, number of valves and cylinders, etc.), a certain minimum volume is required for the reflection or absorption range (or several mufflers can be used: front, central, and rear mufflers).

Fig. 10-40. Combined muffler system

With absorption-type mufflers, the flow of gas is guided through the muffler, and the gas-guiding pipe is perforated. The area between the jacket and perforated pipe is filled with absorbent material. The pulsing flow of gas can expand through the perforation into the area filled with absorbent material. A majority of the vibration energy is attenuated by friction and converted into heat. The flow of gas that leaves the muffler is largely pulse-free. The absorption-type muffler is especially distinguished by good sound suppression in the frequency range above 500 Hz and its low exhaust counterpressure.

In reflection mufflers (also termed interference mufflers), the sound is suppressed by being diverted, by changes in cross section, and by partitions inside the muffler. The corresponding chambers and changes in cross sections must be precisely harmonized with each other. Interference occurs when the sound waves extinguish each along two paths of different lengths (by being 180° out of phase). This principle is particularly effective in the range below 500 Hz.

Pressure peaks of extremely loud vibrations build in resonators (Fig. 10-40, left) that have a particularly low flow loss. The frequency at which a resonator is effective depends mainly on the dimensions (length l, diameter d, and cross-sectional area A) of the pipe extending into the resonator volume V. The resonance frequency f0 can be calculated according to the following equation:

A problematic side effect of reflection mufflers is the excitation of vibration that the wall structure of the muffler experiences from the pulsing exhaust flow. The resulting structure-borne sound can increase the noise emitted from the muffler. This can be countered by selecting sufficiently thick walls of the intermediate plates in the muffler, by using a sufficiently rigid construction of the overall muffler structure, and by using an outer double-layer jacket with or without an absorbent intermediate layer.

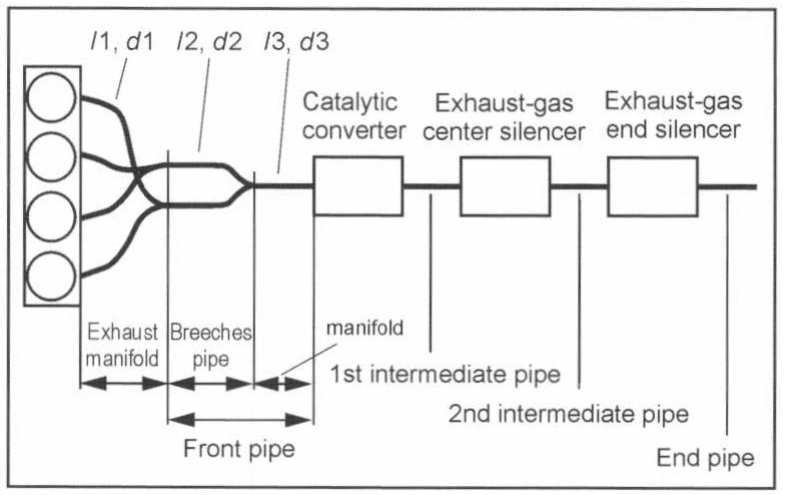

Overall System. Figure 10-41 shows the basic construction of an exhaust system for a four-cylinder engine. When a single catalyst is used, it is necessary to connect the exhaust pipes of the individual cylinders. The exhaust from all the cylinders runs through the manifold that holds a central exhaust gas oxygen sensor to measure the integral air to fuel ratio.

Fig. 10-41. Schematic construction of an exhaust system

The combined reflection/absorption-type muffler or combined reflection/branch resonator muffler are preferred to minimize exit noise. Based on the transient flow, the exhaust system can, given a suitable design, clearly improve the charge cycle similar to the intake system.

The exhaust system largely affects charge cycle properties with three mutually influential factors:

- Gas-dynamic effects

- Exhaust work

- Residual share of gas in the exhaust

The exhaust work is determined by the flow properties of the exhaust system. The flow properties and the gas-dynamic effects in the exhaust system largely determine the residual exhaust gas of the cylinder charge when operating under a full load, which, in turn, strongly influences the combustion properties. The ignition conditions that change with the residual exhaust gas, the inner efficiency, and, hence, the torque behavior is significantly influenced by the adapted ignition points.

Design Criteria. In addition to the requirements for noise suppression and exhaust treatment, there are certain design criteria for the exhaust system related to the charge cycle.

Date added: 2024-11-14; views: 361;