Constant Vacuum Carburetor. Operating Behavior

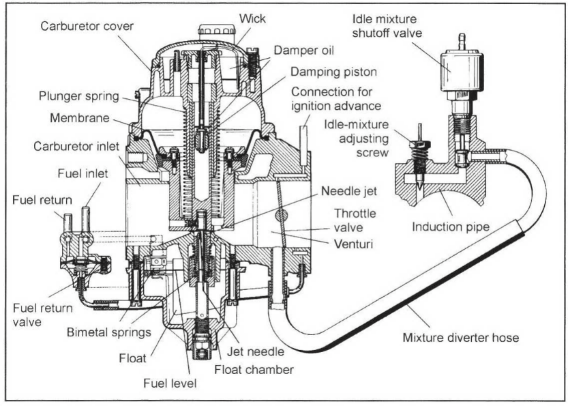

The functional principle of the constant vacuum carburetors is illustrated in Fig. 12-7 with the example of a Zenith-Stromberg CD carburetor. The system works with a variable air cross section in the form of a horizontal draft carburetor. The change in cross section in the intake air duct is caused by a plunger inserted from above. In addition to pressure from its weight, a spring presses the plunger against a bridge, filling the bottom section of the intake air duct. Above the plunger, an area is sealed with a diaphragm that abuts the bottom of the plunger and accordingly compensates the pressure. The bottom of the diaphragm is ventilated toward the inlet. Because of the spring, a linear rise in the pressure differential is required to lift the plunger.

Fig. 12-7. Constant-vacuum carburetor

Because of this pressure differential, the inducted air is accelerated between the inlet and the narrowest place between the plunger and the bridge. The position of the plunger is, hence, a measure of the inducted air stream.

The float chamber is below the bridge. Affixed in the center of the piston is a nozzle needle that extends into a needle jet and meters the fuel as a function of the plunger lift.

With the needle jet, the fuel can be measured on a characteristic curve depending on the air stream. A constant-vacuum carburetor is adapted so that the plunger is completely opened at a full load and approximately half maximum speed. With larger air streams, the constant- vacuum carburetor then operates like a fixed air funnel carburetor. By exploiting the pressure oscillations in the intake system, the mixture ratio of the air and fuel can be set over the entire engine operating range.

Operating Behavior. Hot operation: During engine operation, the carburetor is cooled by the inducted air and the initial evaporation of the fuel. High environmental temperatures and subsequent heat after the engine is turned off can lead to operational problems.

The main problems are high component temperatures in the carburetor that lead to fuel evaporation, an engine with cylinder heads in a uniflow arrangement in which the intake manifold and exhaust manifold are stacked, and the boiling behavior of the fuel.

Improvements in relation to hot operation are possible with

- A hot idling valve to open a bypass for air to circumvent the carburetor. This is primarily used while the engine is idling hot to counter mixture enrichment.

- Fuel return. A valve connected parallel to the float needle valve returns unneeded fuel to the tank. This removes heat from the carburetor.

- Reduction of heat, e.g., by shields and an insulating flange

Altitude compensation: Generally speaking, the mixture is enriched in carburetors proportional to the root of the environmental pressure. For example, the enrichment at 1600 m above sea level is approximately 10%.

The following corrective options exist:

- Influence the pressure in the float chamber

- Influence the differential pressure signal for fuel metering

- Influence the air correction and the metering cross section for fuel

Icing: Because of the evaporation heat of the fuel, heat is drawn from the inducted air and the components of the carburetor, causing them to cool. This can cause water vapor in the air to freeze and, hence, cause problems in operation. The tendency toward ice formation is greatest at air temperatures of 5°C with high humidity, especially in fog.

Icing can be controlled very effectively by additives in the fuel (such as alcohols) that lower the freezing point.

Another possibility is to preheat the intake air and, hence, increase the air temperature.

Distinctions are drawn among the following:

Idling icing: This can arise when ice from the cooling mixture forms on the edge of the throttle valve at low engine loads. In addition, ice can form on the holes through which exists the premixture for idling, as well as on the transition holes, and can distort the differential pressure signal. In addition to using fuel with additives, this can, for example, be dealt with by increasing the amount that the intake air is preheated. The idling ice disappears as the heat increases.

Full-load icing: Full-load icing or air funnel icing arises in older carburetors in which the venturi tube of the main system is located in the middle of the air funnel, and the premixture enters the air over a short path.

This can be dealt with by increased preheating of the intake air or by fuel additives. In carburetors in which the venturi tube is not in the middle of the air funnel, carburetor icing rarely occurs.

Idling speed control: The idling speed can be indirectly controlled with mechanical means by controlling the intake manifold pressure. A separate idle controller is integrated in electronically controlled carburetors.

Engine afterrunning: To prevent the engine from “afterrunning” after being shut off due to the self-ignition of the mixture at hot areas in the combustion chamber, the supply of fuel is shut off along with the ignition.

Overrun: The transition from load operation to overrun must in certain cases be supported in two ways. Added mixture in overrun prevents an undesirable lean mixture. This is done with an additional mixture system. The other possibility is to shut off the fuel in overrun that is normally speed controlled and additionally serves to lower the fuel consumption.

The transition to overrun is accomplished with a throttle valve dashpot or an overrun air valve to minimize load change reactions.

Lambda Closed-Loop Control. There are two possibilities for a lambda closed-loop control:

- In a fixed air funnel carburetor, an additional possibility of intervention to achieve lambda closed-loop control is to provide valves that are in the main system and/or idling system, and that influence the air-fuel ratio. Alternately, an arrangement is used in the form of a partial load control in which a channel to the intake manifold is opened and closed with a solenoid valve.

- With electronic carburetors, the lambda closed-loop control is one of the features of an electronic control unit. The air-fuel mixture ratio is influenced with a choke.

Date added: 2024-11-26; views: 417;