Designs. Number of Intake Air Ducts

The designs can be categorized according to the number of intake air ducts and the spatial position.

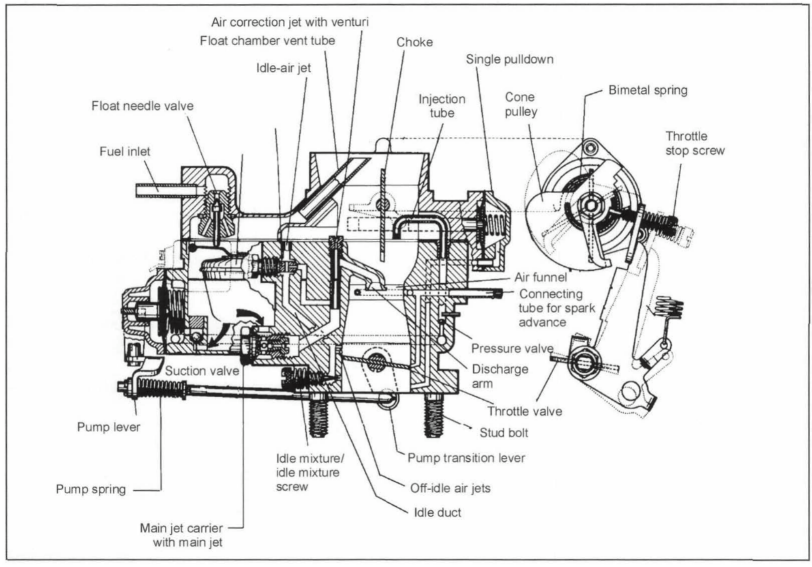

Number of Intake Air Ducts. Single-barrel carburetor: This type of carburetor has an intake air duct with a throttle valve and is the most frequent design. Figure 12-2 shows an example of a downdraft carburetor on which several sizes and expansions of the carburetor are based for “beetle” engines. This is a fixed air funnel carburetor.

The system consists of a float chamber with a float and float needle valve, and internal float chamber ventilation in the inlet. It has a main system with an air funnel, a discharge arm, a compensating air nozzle with a venturi tube, and a main nozzle, as well as a dependent idling system with an idling nozzle, idling air nozzle, idle mixtureadjusting screw, and transition holes.

Fig. 12-2. Downdraft carburetor as a fixed air funnel carburetor

A throttle valve stop screw serves to set the opening of the throttle valve and, hence, control the air and mixture flow for idling. In a development, an idling fuel shutoff valve was added. The accelerator pump with a diaphragm, as well as an intake and pressure valve is actuated via a linkage together with the throttle valve. The orifice of the injection tube is calibrated. A pressure-tapping hole for the spark advance ends at the narrowest cross section of the air funnel. The single-barrel carburetor can be equipped with an automatic choke.

Dual carburetor: A dual carburetor is the combination of two single-barrel carburetors in one housing. Each of the intake air ducts is assigned an equivalent set of systems. Usually, there is only one float chamber and on accelerator pump. There is only one set of the required control organs for the starting control, for example.

The dual carburetor has two parallel intake air ducts in a common carburetor housing, each with a throttle valve that supplies the two separate intake manifolds. The throttle valves are activated simultaneously and can be either on a common shaft or on two parallel shafts. The same holds true for the chokes.

Triple-barrel carburetor: This is a combination of three fixed air funnels and has three inline parallel intake air ducts, each with a throttle valve in a common carburetor housing. The classic application was two triple-barrel carburetors on a six-cylinder boxer engine.

Two-stage carburetor: Over a long section, the air stream is divided into two stages. The first is used for the smaller air throughputs including idling and partial load, and the second stage, frequently with a larger cross section, is opened only to attain maximum output. The two- stage carburetor contains two parallel intake air ducts in a common housing that are both connected to an intake manifold. The two throttle valves in the carburetor are opened sequentially.

The first stage of a two-stage carburetor has all the additional necessary systems. The accelerator pump and starting control are contrastingly required only for the first stage. This is generally directly opened with the gas pedal; the second stage is linked to the opening of the first stage in the carburetor. Similar to single-barrel carburetors, a two-stage carburetor can be combined to form a doublebarrel two-stage carburetor. Usually, double-barrel two- stage carburetors are supplied by means of a float chamber. Such carburetors are used in large volume six- and eight-cylinder engines.

Date added: 2024-11-26; views: 426;