Mode of Operation of the Carburetor

The functional principle of the carburetor is based on the fact that by reducing a cross section in an air-conducting channel, there is less pressure than in the larger cross section or than in the atmosphere due to the greater flow rate in the narrow cross section.

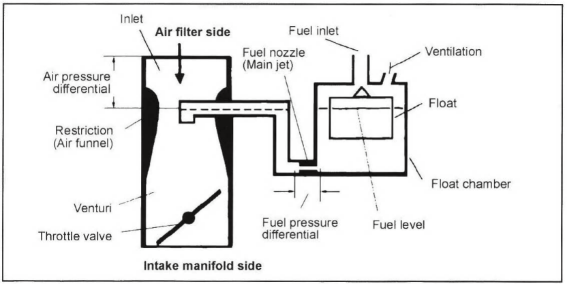

This pressure differential is used to supply fuel to the air through suitable cross sections (Fig. 12-1).

A characteristic feature of carburetors is the generation of a differential pressure signal from an air stream, and its direct conversion into a fuel stream. In principle, the air side and fuel side are designed identically and can be described with the Bernoulli equation for fluid mechanics.

Given a simplified assumption of an incompressible flow, the following equation results for the air mass flow:

A carburetor has a fuel accumulator (float chamber) with a free fuel surface whose level is kept constant. A distinction is made between the following:

Constant air funnel cross section (fixed air funnel carburetor) (Fig. 12-1): Most carburetors are constructed according to this principle. In the intake air duct, there is a venturi-shaped air funnel with a fixed cross section to which a main nozzle is assigned. In small air streams, the pressure differential generated with the air funnel remains low. The pressure differential between the inlet and the intake manifold must, therefore, also be used to meter the fuel.

Fig. 12-1. Functional principle of the carburetor

Carburetors with a constant air funnel cross section require several nozzle systems and an accelerator pump for an appropriate fuel supply in the engine map. To compensate for the influence of the different Reynold’s numbers in the fuel and airflow, compensating air is mixed with the fuel.

Variable air funnel cross section: The intake air duct cross section is normally changed with a movable element. The following items are conventionally used:

- An air valve

- A piston that penetrates the channel

- A swiveling lever that constricts the channel

This allows a wide range of air streams to be controlled using a differential pressure that changes only slightly. For symmetry, a conical nozzle needle that extends into a needle jet is connected to a movable element to meter the fuel.

If the movable element also works while the engine is idling, the fuel can be dosed with the needle jet for the entire range of the air streams in an idling engine warm from operation. This is termed a constant vacuum carburetor.

When the movable element does not work while the engine is idling and rests on a stop, this is termed a “constant pressure stage.” Constant pressure stages are frequently used as a second stage in multistage carburetors.

Date added: 2024-11-26; views: 404;