Remediation Methods

Each hazardous waste site is characterized by a unique set of challenges. Numerous remediation methods may be employed to meet the corrective needs of a particular site. Thorough site characterization helps determine the sources and extent of contamination, and which methods may be viable. There are common, risk-based goals for contaminated sediment and soil remediation.

The Environmental Protection Agency’s (EPA) contaminated sediment management goals consist of preventing the increase of contaminated sediment volume, mitigating existing contamination, conducting dredging operations in a safe manner, and improving sediment management techniques. Objectives for contaminated soil remediation used by the National Research Council (NRC) include mass removal, reduction of source transport, and plume size reduction.

As per the Code of Federal Regulations, title 40, Section 300.5, a treatment technology is defined as “any unit operation or series of unit operations that alter the composition of a hazardous substance or pollutant through chemical, biological, or physical means so as to reduce toxicity, mobility, or volume of the contaminated materials being treated. Treatment technologies are an alternative to land disposal of hazardous wastes without treatment" .

The Federal Remediation Technologies Roundtable, FRTR, produces the Remediation Technologies Screening Matrix and Reference Guide, a document supported by various federal agencies. The guide assists remedial project managers and associated parties in evaluating and selecting appropriate treatment technologies based on variables such as source material, overall cost, technology performance, contaminant type, and cleanup time.

The Screening Matrix states that most treatment technologies use one of the three strategies: contaminant destruction, extraction/separation, or immobilization. Treatment by destruction alters contaminants to less toxic by-products. Extractive technologies aim to transfer contaminant mass to a separate phase (e.g. solvent and gas) to effectively remove contamination from affected media. Lastly, immobilization or stabilization technologies reduce contaminant mobility and minimize contaminant leaching.

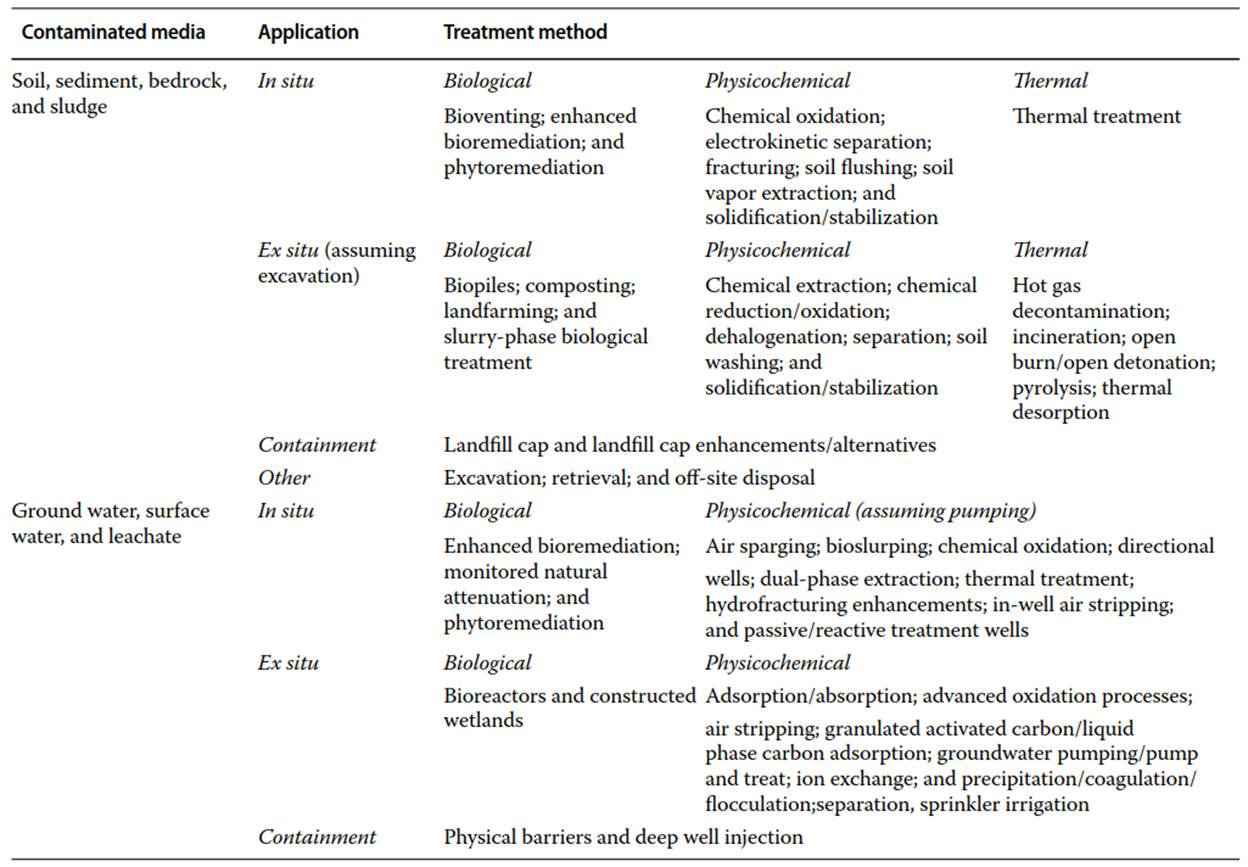

Table 1, adapted from the FRTR Screening Matrix, categorizes several treatment technologies based on contaminated media, type of application (e.g. ex situ, in situ, and containment), and type of treatment (e.g. biological, physical/chemical, and thermal). Contaminated media are subdivided into: (i) soils, sediments, bedrock, and sludge and (ii) ground water, surface water, and leachate, based on similar environmental conditions and remediation methods.

Table1. Types of treatment technologies used in contaminated site remediation

Treatment technologies are applied in different ways: in situ, ex situ, and containment. In situ methods treat contamination in place, without need for removal. In situ remediation approaches are desirable for cost-effectiveness and reduced ecological impacts. Ex situ removes contamination by excavation of soils and sediments, or by pumping for groundwater. Ex situ technologies are more resource intensive compared to in situ technologies, but take less time. Containment technologies reduce contaminant mass transfer while not altering chemical structure or requiring removal.

Types of treatment technologies include biological, physicochemical, and thermal processes. Biological processes use microorganisms to metabolize, and therefore degrade, pollutants to less toxic compounds. Physicochemical processes effectively destroy or separate contamination. Lastly, thermal treatment applies heat to volatilize, destroy, or immobilize contamination. Contaminant type and media properties place limitations on certain treatment processes. For instance, biological and chemical treatments such as enhanced bioremediation and chemical oxidation require aqueous phase contamination.

These treatment technologies are limited in media with highly sorbed contaminants because they require a two-step mass transfer process: desorption from soils/sediments to the aqueous phase, followed by aqueous phase treatment. Since mass transfer is the rate-limiting step of this two-step remediation process, additional treatment technologies to enhance mass transfer may be needed for biological or chemical treatment to be practical in these circumstances.

This article focuses on ultrasound, a treatment technology categorized as an advanced oxidation process (AOP) that can be applied in situ or ex situ. AOPs generate highly oxidizing, hydroxyl radicals (•OH) to degrade aqueous pollutants to less toxic compounds or to mineralize compounds to CO2 and H2O. Examples of AOP treatment technologies are ultraviolet (UV) irradiation, catalyzed hydrogen peroxide (H2O2), and ozone (O3). Because AOP mechanism of reaction is •OH, AOPs differ from chemical oxidation, as listed in Table 1. Therefore, since O3 may form •OH under appropriate conditions, O3 addition is both an AOP and chemical oxidant. An example of a chemical oxidant that is not an AOP is permanganate (MnO4-). Both AOPs and chemical oxidation require desorption prior to degradation.

Date added: 2025-01-04; views: 369;