Department Stores and Supermarkets. Workshops: Woodworking

When designing retail outlets all national regulations (building and planning, fire, health and safety at work etc.) should be observed.

Basic dimensional guidelines give the minimum heights of spaces in shops and storage facilities as:

up to 400 m2 retail floor space 3.00m

over 400m2 retail floor space 3.30m

over 1500m2 retail floor space 3.50m

Ventilation ducts or other structures should not reduce the required clear room heights. If possible rooms up to 25 metres wide should be free of columns. The load-bearing capacity of floors should be designed to take additional loads such as light fittings, suspended ceilings, decoration, ducts, sprinkler systems etc. (approximately 20kp/m2). In the shopping areas and store-rooms it should be 750-1000kp/m2, and 2000kp/m2 for ramps. The floors connecting sales areas, stores, and delivery ramps should be at the same level. Note that delivery ramps or platforms are 1.10-1.20m above ground level.

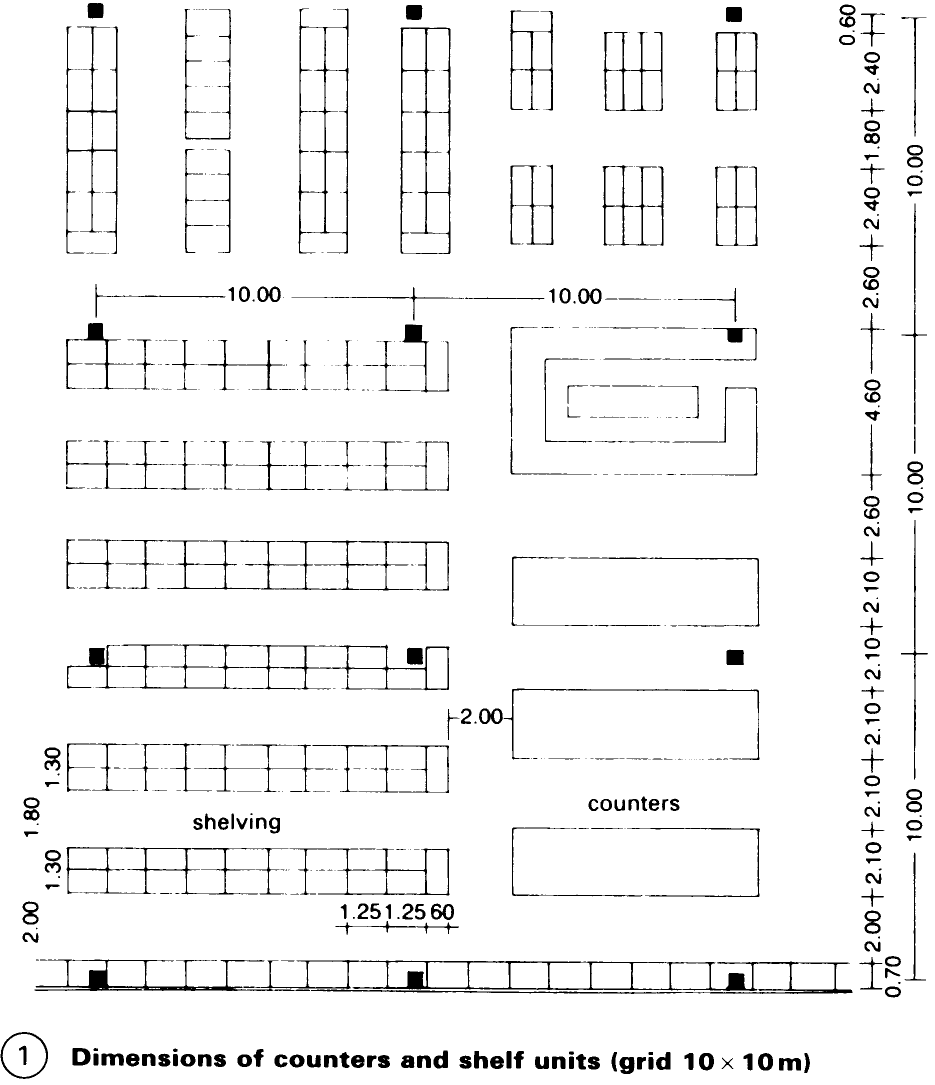

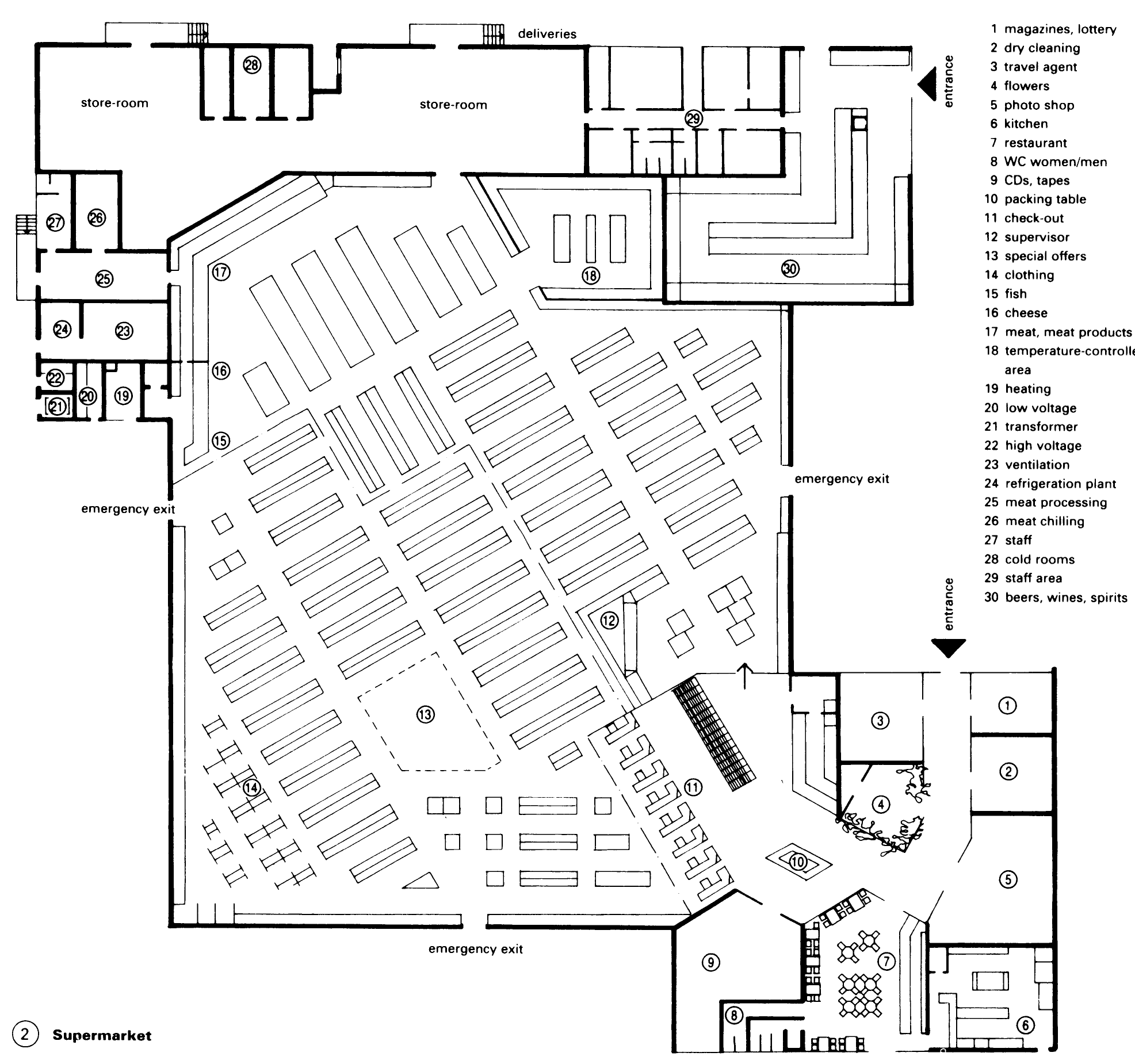

Shelf arrangements are developed from considerations of how best to lead customers past all the different ranges of goods – (1) – (2).

The department store is essentially a very large shop, generally on several floors, selling a wide variety of goods, including clothes, household goods and food. Their design should provide maximum flexibility to permit frequent adjustments required for the seasonal sales patterns. The food department is the only one purpose designed. A main structural grid between 5.4 and 6m is commonly used, with 5.4m being considered optimum.

The increasing requirement for car-parking space has led to the growth of purpose-built out-of-town shopping centres. These in turn have encouraged the development of huge DIY warehouses, discount markets and 'hypermarkets', which are modelled along supermarket lines.

The largest hypermarkets are about 250000 m2. Shoppers generally purchase a greater quantity of goods in hypermarkets than in supermarkets and therefore larger size trolleys are used. This needs to be considered in the design. The 'superstore' is a further development of the hypermarket.

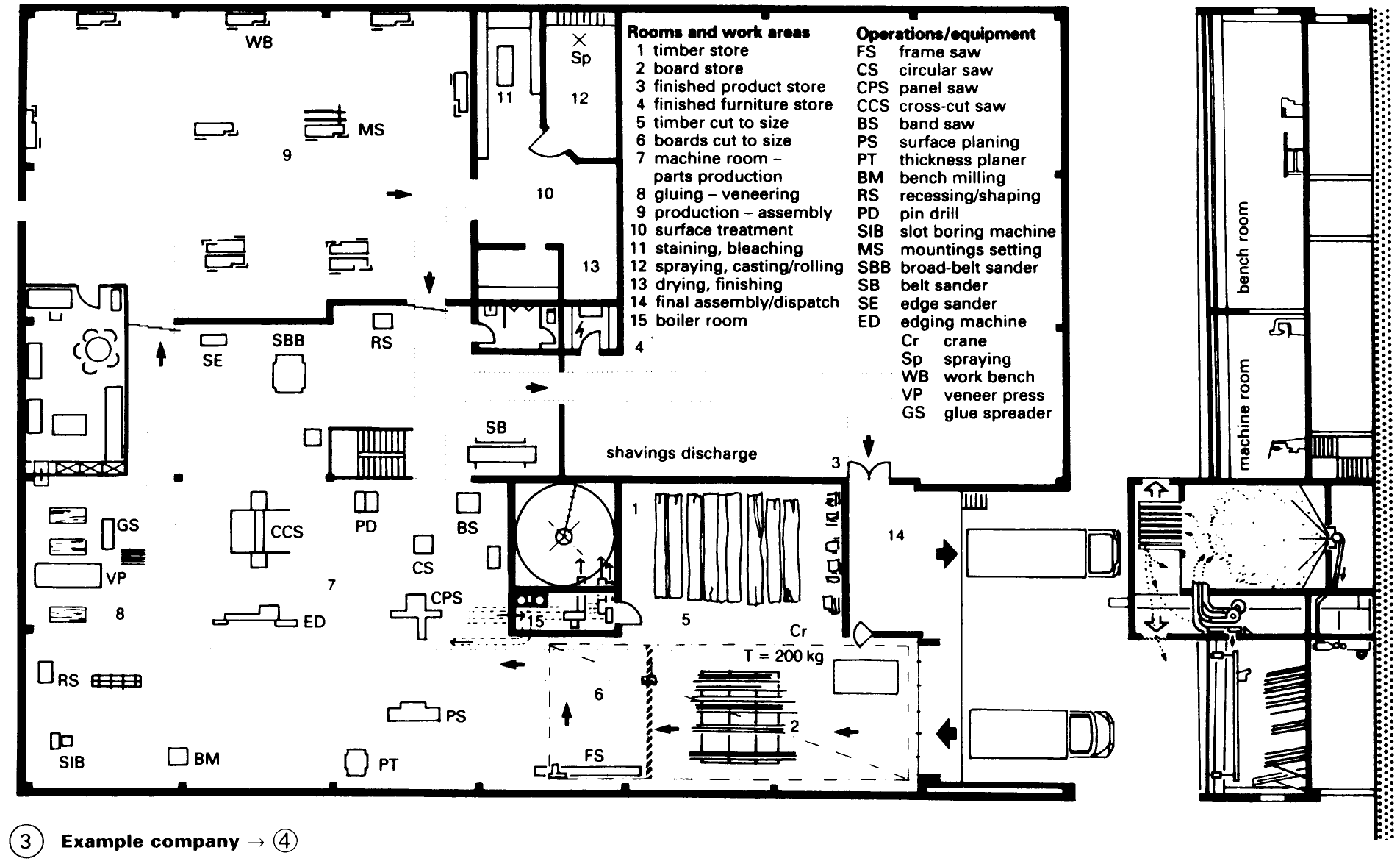

Workshops: Woodworking. Generally the change in plan form from long sheds to more compact developments - (2) - (3) improves economy: the site is more efficiently used; routes are shorter in mixed production; service ducts are shorter. Multistorey buildings are not appropriate for production areas but are recommended for offices, ancillary rooms and store rooms for small and/or valuable articles. Predominant building types have steel frames with reinforced concrete and metal or timber cladding. Walls and roofs of large manufacturing units should have good heat and sound insulation. Windows of insulating glass are mostly fixed; natural lighting from above is possible; a smaller proportion of window area as required by regulations should serve for ventilation and view.

Space requirements (for examples shown): an average of 70-80 m2per employee (without open storerooms).

An extractor system is required in virtually all cases to remove wood chippings, sawdust and wheel dust, both for the sake of regulations on health and safety at work and on economic grounds. The arrangement of machines is determined according to the sequences of operations. Rubber bonding to metal mountings can reduce high levels of machine noise.

In small companies with up to ten employees, general production flow can be in a line or L-shaped. In medium-sized companies with more than ten employees, a U-shaped or circular (or square) arrangement gives a better flow. In the latter case functions are combined: gate, load and unload, ramp, supervision, checking, goods in, dispatch.

Work sequence: timber store, cutting area, drying room, machine room, bench workshop, surface treatment, store, packing. Machine room and bench workshop is divided by a wall with doors - (3). Office and foreman's room are glazed, with view of workshop. Workshop floor: wood, wood-block or composition flooring. All workstations should face the light. Continuous strip windows, high sills (1.00-1.35m).

In the workshop, there should be enough space to give each worker not only sufficient bench room, but also the required space to assemble the work. A large number of joiners' shops are mechanised; larger ones have separate assembly and machine shops, but in smaller shops machines may be grouped at one end of the work area.

Rooms and areas. Stores: for rough timber, boards, veneers, glass, plastics, auxiliary materials and fittings; temporary stores; stores for finished and partially finished products.

Workshops: For drying wood, and cutting timber, boards and veneers. Machine shops for parts, processing timber, boards, gluing and veneering, production and assembly, bench work, bonding, surface treatment, final assembly and dispatch. Metal working facilities are often also required.

Administration and management: works office (foreman), technical offices, commercial offices, management and secretarial offices, meeting room, sales room.

Social and ancillary rooms should have wood-block or composition flooring, (not concrete).

Storage areas should be dust free (fine dust blunts tools).

Machines should be set up to match sequence of work. All workstations should face the light. Window area should be approximately 1/8 of floor space.

Operating design (planning): determine all factors relevant to the operational needs of the business. Machines: utilisation, costs and economic feasibility, power requirement, load-bearing capacity of floors, space requirement, costs. Production processes: production times, staffing levels, organisation of technical operations. Materials: types, quantities, weights, space requirement, storeroom dimensions. Energy supply: heat, electricity, compressed air. Waste materials: type, space requirement, waste management. Sequence of operations and tasks. Plan of operational utilisation of space (layout).

Date added: 2023-01-05; views: 646;