Vehicle Repair Shops

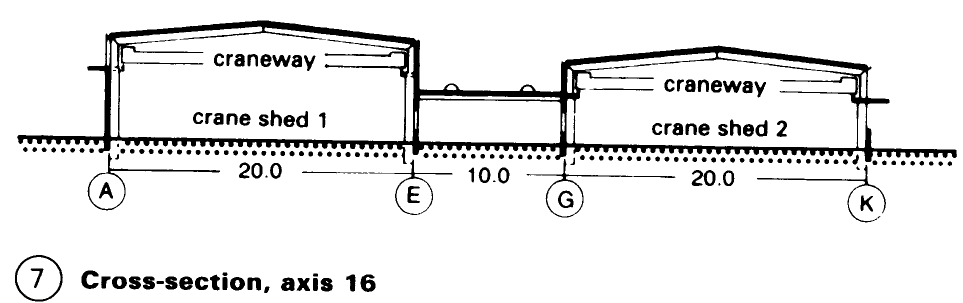

Usually single storey of light steel construction or prefabricated elements. Single-span shed without columns is preferable. Choose an appropriate module to allow extension.

Workshop floors should be sealed against grease and oil. Petrol and oil traps are essential. Provide extractor duct for exhaust fumes. Provide automatic doors with hot-air curtain. Installation of ducts for electricity, compressed air, used oil and water is recommended. For companies with a service department choose a location with good transport links if possible, even if development and building costs are higher. If the site is on the edge of town provide appropriate advertising and transport for customers.

Basic rules: site built area 1/з to 2/з unbuilt area. Allow for possible extension. For larger companies the average area is 200m2 per workshop employee. Added to this are rooms for sales, works office, customers' waiting room, social rooms etc. Check mains services. For car washes high water consumption should be taken into account.

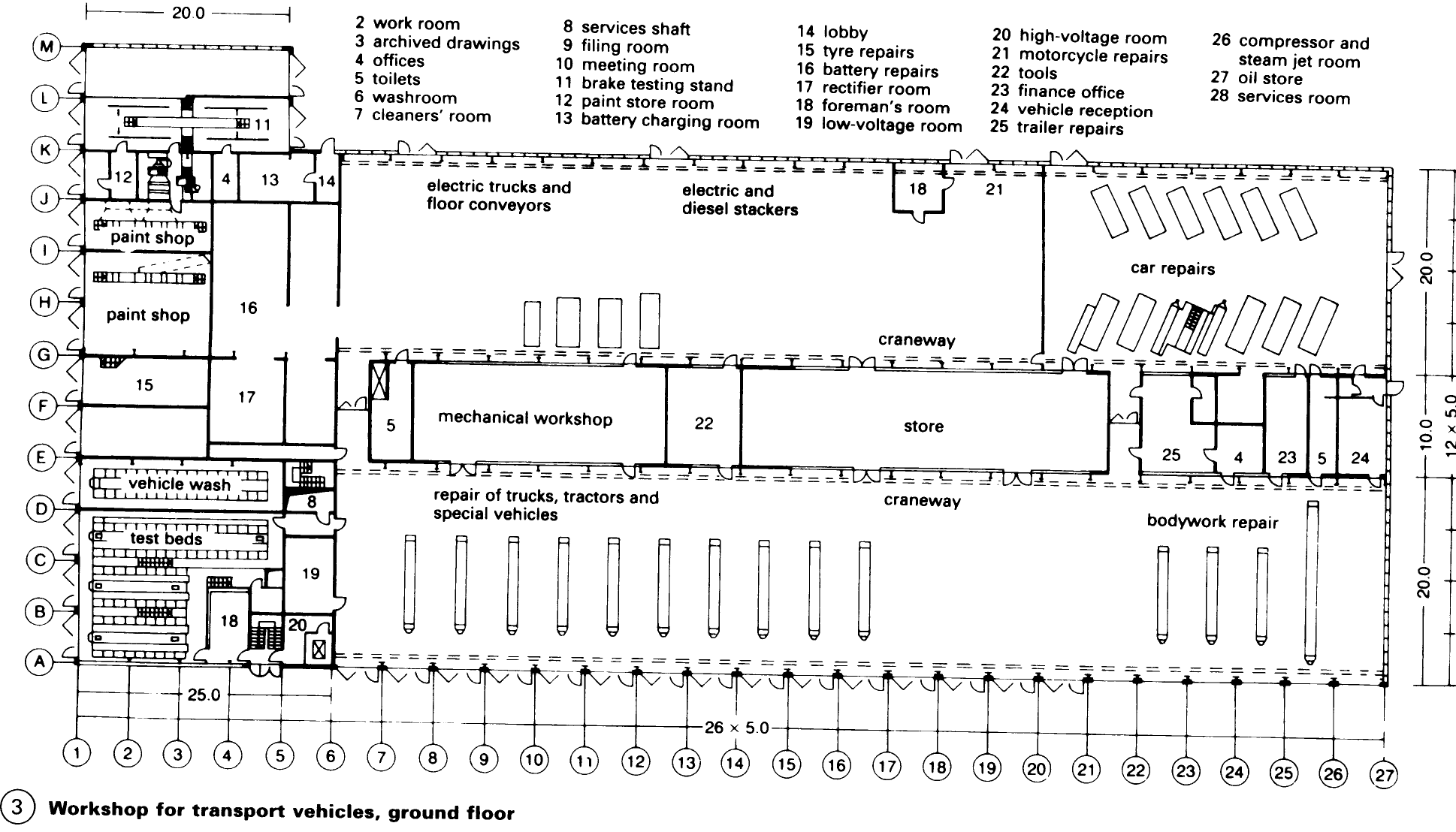

Large company workshop (3) – (7) for lorries, towing vehicles, special vehicles, containers and trailers, cars, fork-lifts and electric vehicles.

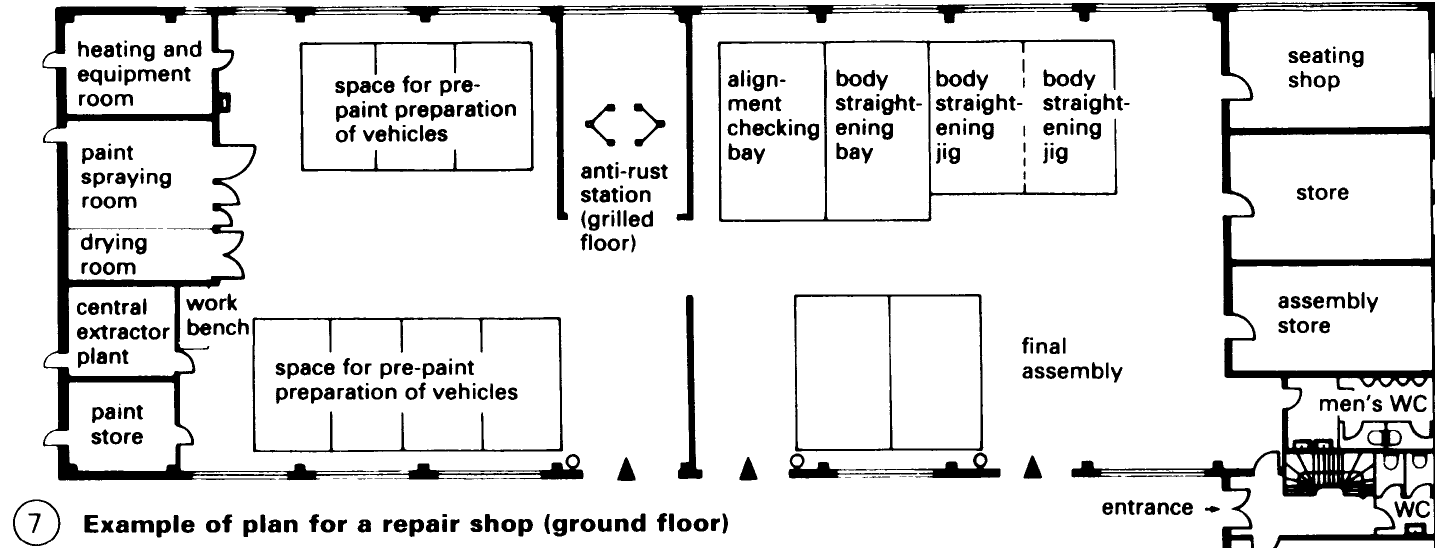

It is not possible to use a fixed scheme when planning and building car-body repair shops, as local conditions usually vary considerably. Instead, it is necessary to use a planning method which is based on service and working procedures and which takes company-specific features and needs into account.

On completion of the first building phase the operation should be fully functional. Thereafter, it should be possible to enlarge the company at any time.

In a car-body repair shop the workstations are virtually all fixed and equipped with different tools. They should be designed in such a way that tasks can be carried out economically and in the shortest possible time, with minimum movement.

For companies involved in vehicle repair it is useful to structure the workshop on a 'performance production principle'. Vehicles are driven into the workshop and remain at the designated repair bay until the work is finished.

Example - (7) shows a plan of a bodyshop for repairing and servicing cars and small trucks, employing about 14 people in the workshop and two in the offices. All functional areas where repair work is done are on one level and kept apart from the customer area by separate entrances.

To avoid noise and dust pollution the paint- and bodyshops should be separate. Due to the different sizes of vehicles to be repaired and the different kinds of repair work there is only a limited possibility of making fixed plans for workstations and machine positions.

The dimensions of the workstations should therefore be such that even when the repair shop is fully occupied, mobile work benches or the required tools can be moved to the vehicle. Lay service ducts overhead.

In paintshops use the following standard dimensions for spray booths (clear dimensions): length 7.00m, width 4.00m, height 2.85m. Design: construction in insulated sheet metal or brickwork or self-contained system for use outdoors.

Customer reception area should be on the ground floor; accounts, manager's office, social rooms etc. can be on upper floors.

Date added: 2023-01-05; views: 628;