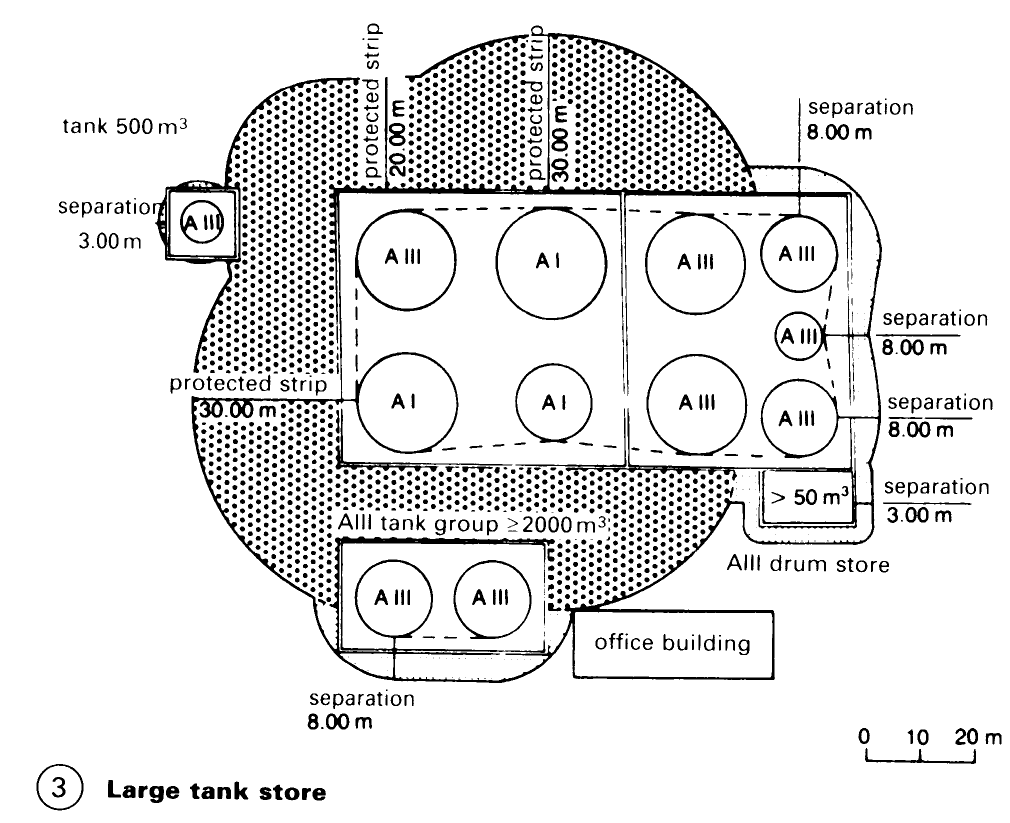

Heating: Oil Storage Tanks

The fuel containment enclosures must be designed so that, if fluid escapes from a storage device, it is prevented from spreading beyond the enclosure area. The enclosures must be able to safely contain at least one-tenth of the volume of all the tanks it contains, and at least the full volume of the largest tank.

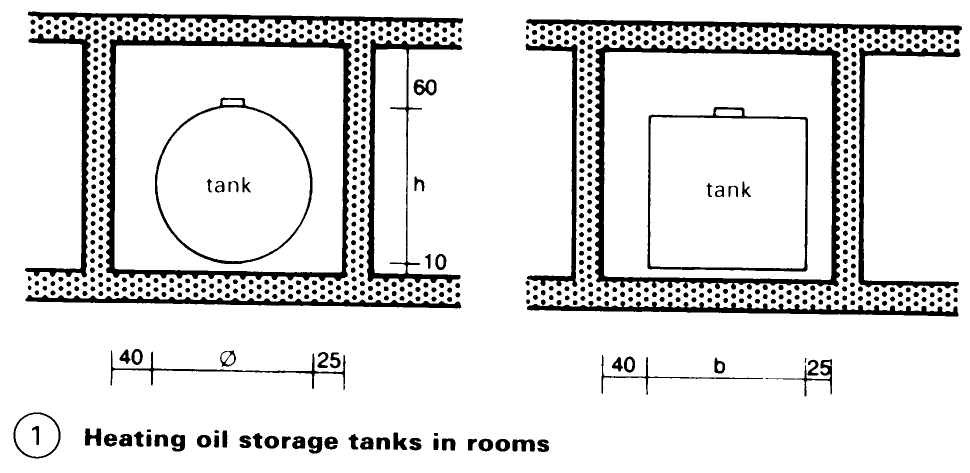

Tanks in rooms: containment enclosures are required if the storage volume is > 4501, unless the storage tanks are of steel with a double wall. Tanks can have a capacity of up to 1000001, with leakage indicator devices, or manufactured from glass fibre reinforced plastics of an approved type of construction, or they can be metal tanks with plastic inner linings of an approved form of construction. Containment enclosures must be constructed from non-flammable fire-resistant materials of adequate strength, leakproof and stability, and must not contain any outlets. The tanks must have access on at least two sides with a minimum clearance of 400mm from the wall, or 250mm in other cases, and at least 100mm from the floor and 600mm from the ceiling – (1).

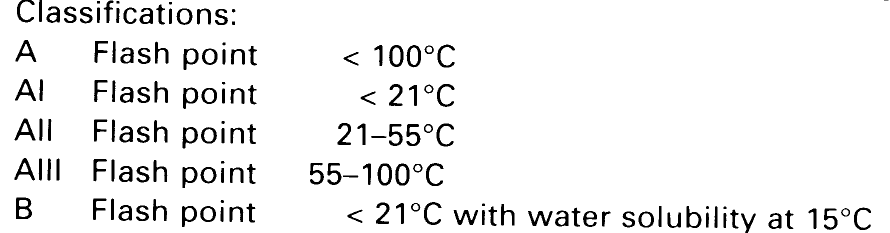

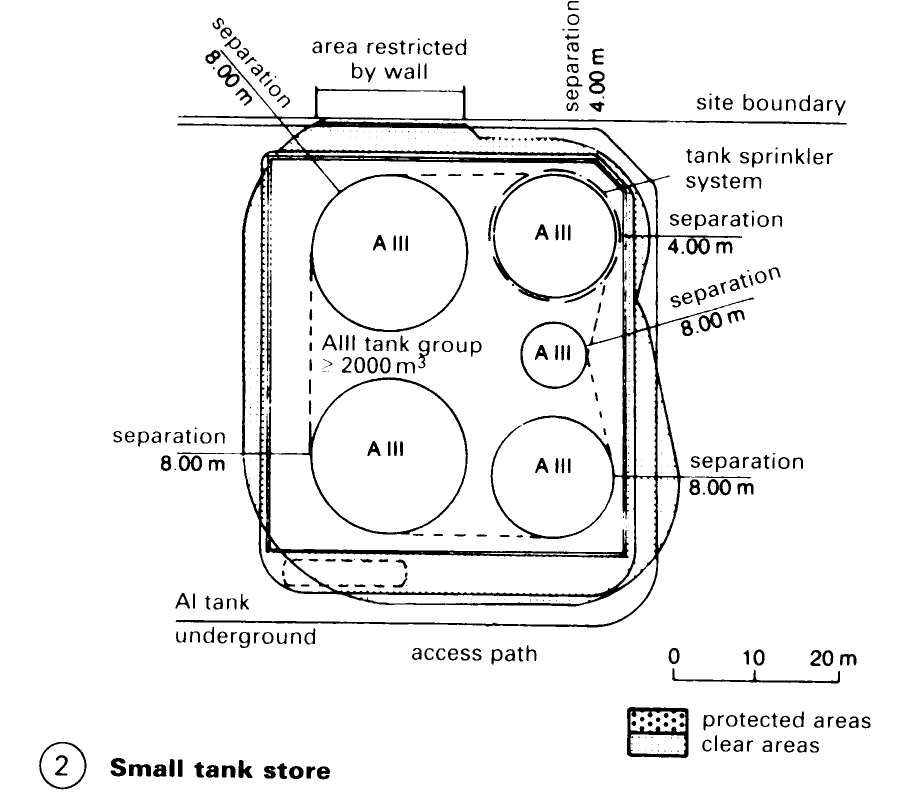

Outside tanks, above ground: containment enclosures are required for capacity >10001. Otherwise, conditions are as for tanks in rooms. Storage areas can be ramparts. For tanks >100m3 capacity, clearance to the ramparts, walls or ringed enclosures must be at least 1.5m. For vertical cylindrical tanks of capacity <2000m3 in square or rectangular catchment areas, clearance may be reduced to 1 m. Arrangements must be made for the removal of water and these must be capable of closure. If water can discharge by itself, then separators must be built in. Above ground facilities require protected access. A distance of at least 3m from neighbouring facilities is required if there is a storage capacity >500m3 and correspondingly more as capacity increases, to a clearance of 8m for a storage capacity of 2000m3. Access routes are required for fire-fighting appliances and equipment – (2) – (3).

Underground tanks: > 0.4m clearance of tanks from boundaries; >1m from buildings. Underground anchorage of the tanks is required to prevent movement of empty tanks in the presence of ground water or flooding. Backfilling is required to a depth of 0.3-1 m above the tanks. Also, 600mm diameter access openings into the tanks are needed, serviced by a watertight shaft with a clear width of at least 1 m, and 0.2 m wider than the tank access opening lid. The shaft cover must be able to withstand a test proof loading of 100kN where vehicular access is to take place. Filling points are subject to approval for combustible fluids in hazard classes AI, All or B. They must be immediately accessible, with protected access. The ground surface must be impermeable and constructed of bitumen, concrete or paving with sealed joints. Drainage outlets with separators, overfilling protection, and emptying and washing facilities for tanker vehicles are required.

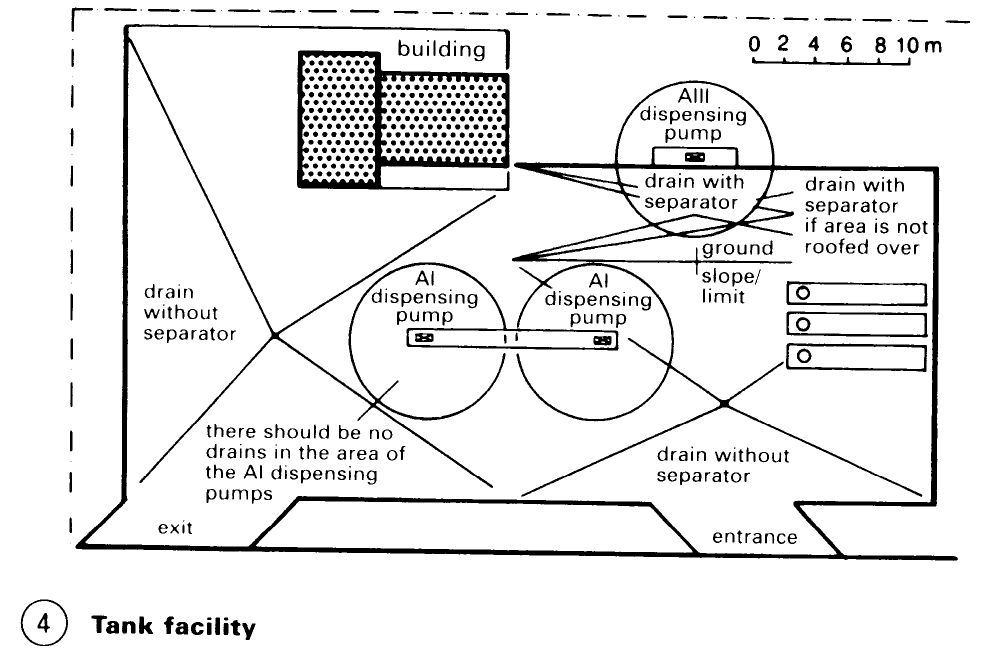

Tankage facilities for the fuelling of all vehicles with combustible fluids in hazard classes AIM (e.g. heating oil and diesel fuel) must not be stored together with those in hazard classes AI, All or B. Neither must the effective regions of separators and operating surfaces of such storage areas overlap – (4).

Requirements for all tanks: Ventilation and venting facilities must be sited at least 500mm above the access cap, or above ground level in the case of underground tanks, and be protected from the ingress of rain water. Devices must be provided to determine the filling levels in the tanks. Access openings must have a clearance diameter of at least 600 mm and visual inspection openings, 120mm diameter. Protection must be provided against lightning and electrostatic discharge. Additional provisions cover flame spread resistance, internal and external corrosion, and fire extinguishers of the appropriate type. Tanks for diesel fuel or heating oil EL with a capacity over 10001, must have fill meters and overfill protection.

Date added: 2023-01-05; views: 608;