Cold Storage Rooms. Meat Cooling and Refrigeration

To determine the cooling requirements for cold rooms, attention must be paid to the requirements of the commodities stored; humidity content, air changes, cooling or freezing duration, type of storage, etc. Also, consider the specific heat of the goods, internal environment, method of manufacture, position, heat from lighting and movements within the cold store. Calculation of the cooling requirement takes the following form.

(1) Cooling/refrigeration of the goods (cooling to the freezing point - freezing - supercooling) (Q=m x cp x Δt); if goods are to be frozen solid, the necessary heat must be removed at the freezing point, and, subsequently, the specific heat of the frozen goods is lower; the humidity extraction is approximately 5%

(2) Cooling and drying of the extracted air

(3) Heating effects through walls, ceiling, floor

(4) Losses: movements in and out of storage (door opening), natural and electric lighting, pump and ventilator operation

(5) Condensation of water vapour on walls

The cold storage of freshly slaughtered meat is cooled from 303.15K to a temperature of 288.15K. This is achieved by placing it in a temperature of 280.15-281.15К at a relative humidity of 85-90% in the pre-cooling room for 8-10 hours, and then storing it at 275.15K-281.15K at a relative humidity of 75% for up to 28-30 hours in the cool room. Cooling and storage takes place separately. Weight loss over 7 days is 4-5%. Today, rapid cooling is used increasingly, no pre-cooling stage, meat is cooled from a slaughter temp, of 303.15K to a storage temp, of 274.15K, with 60-80 circulations of the air per hour and at a relative humidity of 90-95%.

Meat cooling and refrigeration. The freezing process changes the condition and distribution of the water in meat, while the meat composition remains unchanged.

Beef is frozen to 261.15K and pork to 258.15K, at a relative humidity of 90%. Duration of freezing: mutton, veal, pork, 2-4 days; beef, hindquarters 4 days, forequarters, 3 days. Correct thawing period: 3-5 days to 278.15-281.15K, restores the meat to a fresh condition.

Recently, mainly in the USA, rapid freezing methods have been employed, at temperatures of 248.15-243.15K, involving 120-150 air circulations per hour. The advantages are: lower weight loss, increase in tenderness, replacement of the curing process, lower liquid loss, good consistency and preservability after thawing.

Storage duration is dependent on the storage temperature; for example, for beef the storage duration is 15 months at 255.15K, 4 months at 261.15K and 3 months at 263.65K.

Cold room volume: 1 m3 is suitable for the storage of 400-500 kg of mutton, 350-500 kg of pork, 400-500 kg of beef, with a standard stacking height of 2.5m.

Refrigeration of fish. Fresh fish can be maintained in this condition on ice at 272.15K and at a relative humidity of 90-100% for a period of 7 days. Longer storage times can be achieved through the use of bactericidal ice (calcium hypochlorite or caporite). For even longer storage, rapid freezing to 248.15 -233.15K is required, if necessary use glazing with fresh water to keep air out and prevent drying up. Fish crates are 90 x 50 x 34, giving a weight of approx. 150kg.

Refrigeration of butter. Butter refrigerated to 265.15K has a storage duration of 3-4 months and a duration of 6-8 months at a temperature of 258.15-252.15 K. Lower temperatures can provide a period of up to 12 months. The relative humidity should be 85-90%. Butter drums are 600mm high with a diameter of 350-450mm, resulting in a weight of 50-60kg.

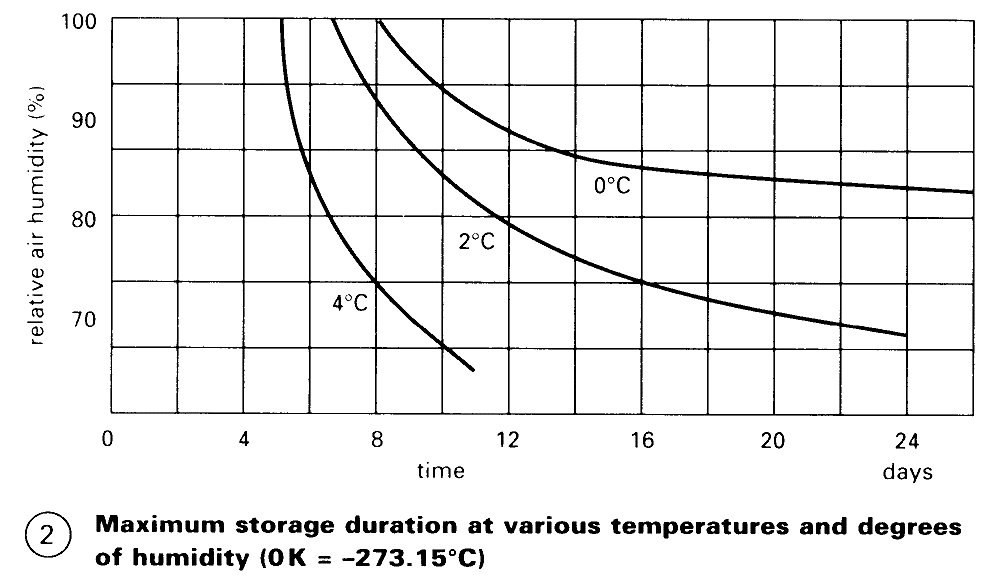

Refrigeration of fruit and vegetables. Immediate cooling is required, since a reduction of temperature to 281.15K delays ripening by 50%. Storage duration depends on air quality (temperature, relative humidity, movement), variety, maturity, soil quality, fertilising, climate, transportation, pre-cooling, etc.

Cooling of eggs. Cold storage eggs are those stored in rooms whose temperature has been artificially controlled to a value lower than 8°C. Such eggs must be identified as 'cold storage eggs'. To avoid sweating, if the temperature outside the cold storage room is more than 5°C greater than inside, the eggs must be warmed in a defrosting room with controlled air conditioning on removal from cold storage. The area of the defrosting room is approx.12% of that of the cold storage room. The warming-up time for quarter crates is approx. 10 hours; 18-24 hours for complete and half crates.

Stacking of the quarter crates in the defrosting room: around 5000-6000 eggs (approx. 400kg gross) per m2. Crates of 500 eggs are 920mm long, 480mm wide and 180mm high; for 122 dozen (= 1440) eggs, 1750 x 530 x 250mm. A basis for calculation is 10-13 crates for 30 dozen, occupying 1 m3 in the storage room; since one egg weighs 50-60 grams, there is a weight of between 180-220kg of eggs in the 1 m3. A net volume of 2.8m3 cold room capacity is required for 10,000 eggs. Two million eggs fill 15 freight wagons. For export, the eggs are packed in crates of 1440 items; wood shavings are used as packing between the eggs, giving a gross weight of 80-105kg. For Egyptian eggs, this weight is 70-87 kg, tare, i.e. the empty crate and shavings weigh 16-18kg.

One wagon contains 100 half export crates holding 144,000 eggs or 400 'lost' crates with 360 items each. Standard crates for 360 eggs are 660mm long, 316mm wide and 361mm high (the so-called 'lost' crates). They can be divided into two by a central partition. Cardboard inserts are used. The crates are made from dry spruce; pine is unsuitable. Stacked 7 crates high, 10,000-11,000 eggs can be stored on a net area of 1 m2. Dry air, at 75% humidity and air-tight packaging is used, with cube-shaped crates with 360 eggs in each, in protective cardboard pockets. If the eggs are exposed to the ingress of air, the air humidity can be 83-85%. The air humidity in the store is controlled by first supercooling then heating it within the ventilation system.

The weight loss during the first months in cold storage is severer than later months; a weight loss of 3-4.5% occurs after 7 months. Eggs can also be conserved in a gaseous atmosphere of 88% C02 and 12% N, after Lescarde-Everaert, in gas-filled autoclaves at around 0°C. This preserves the eggs in their natural state. Uniformity of temperature and air humidity are important factors. Ozone is frequently introduced into egg cold storage rooms. The cooling requirement during storage is 3300-5000 kJ/day per m2 of floor surface - higher during the period when eggs are introduced. The storage periods run from Apr/May to Oct/Nov.

Date added: 2023-01-05; views: 678;