Thermal Insulation. Types of Construction

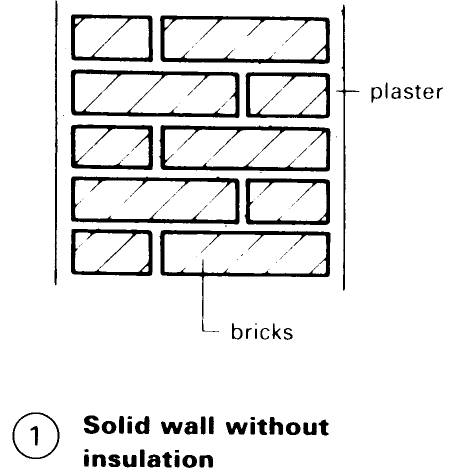

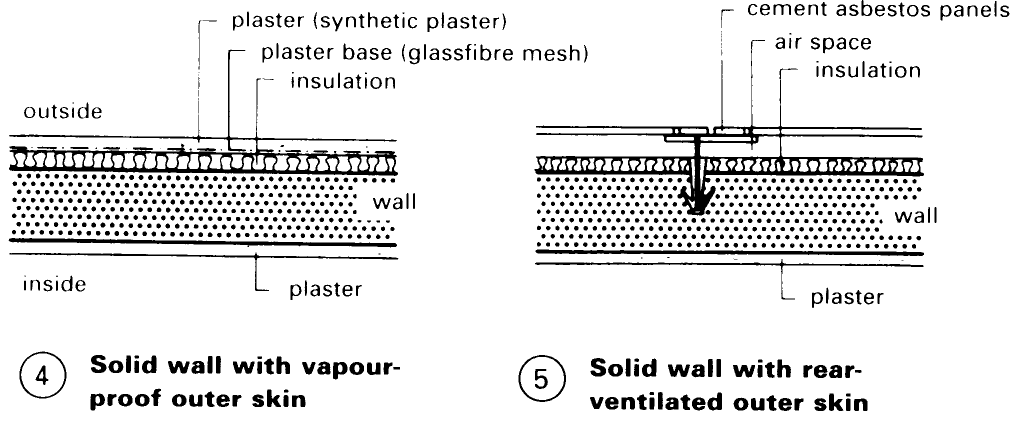

Construction without vapour barrier – (1). Conventional construction contains no vapour retarding layers. Layers should be provided so that no condensation occurs: for sufficient thermal insulation, the layer factor λ should fall from inside to outside. In the case of very damp rooms (e.g. swimming pools), the vapour pressure variation should be checked either graphically or by calculation.

Note: on the outside of thermal insulation layers with normal plastering, there is a danger of cracking due to the build up of heat and low shear strength of the base material; therefore, glass fibre reinforced finishing plaster should be applied.

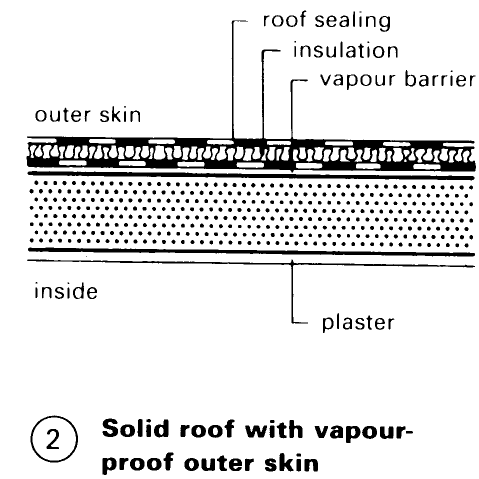

Construction with vapour barrier - (2). In more recent building construction ('warm roof', 'warm fagade'), there is a vapour impermeable outside layer, resulting in the necessity for an internal vapour barrier. On vertical components, this is difficult to accomplish; a better form of construction is to provide a rear-ventilated outer skin (except for prefabricated walls). Note: the thermal insulation, including the air boundary layer on the layers up to the condensation barrier, must not exceed a specific level of contribution to the resistance to heat. In solid constructions, protection of the vapour barrier against mechanical damage can be achieved by means of a protective layer. Since no high pressure - in the sense of a steam boiler - occurs on the inside of the vapour barrier, only vapour pressure, the frequently recommended 'pressure compensation' provided by this layer, is not in fact required.

Construction with rear ventilated outer skin – (5). Rear ventilation avoids the vapour barrier effect of relatively vapour tight outer layers. It works by exploiting height difference (min. fall 10% between air inlet and air outlet). If there is only a small difference, then a vapour-retarding layer or vapour barrier is required (arrangement – construction with a vapour barrier), otherwise there will be excessive vapour transmission and condensation at the outer skin. The layering on the inner skin should be as for construction without a vapour barrier. However, the inner skin must always be airtight.

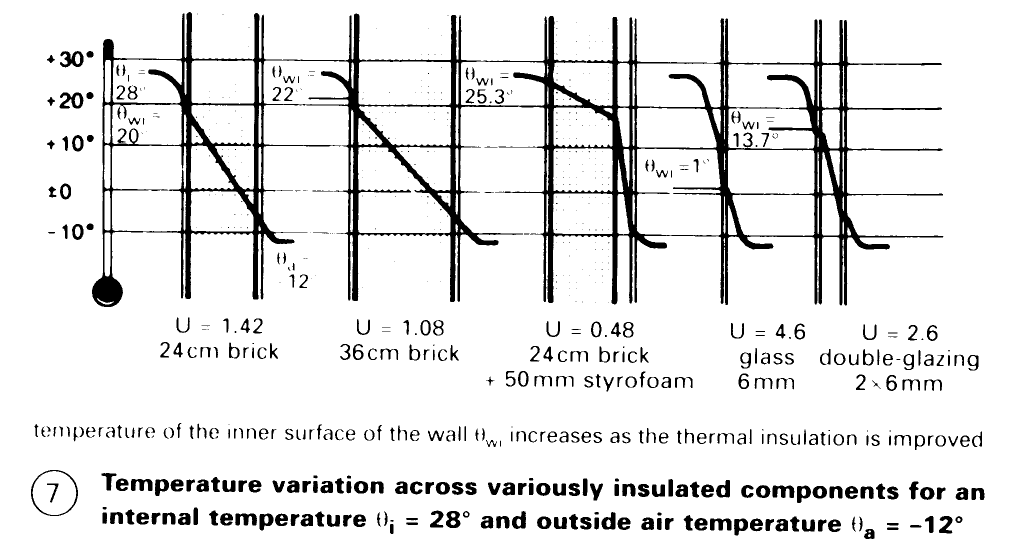

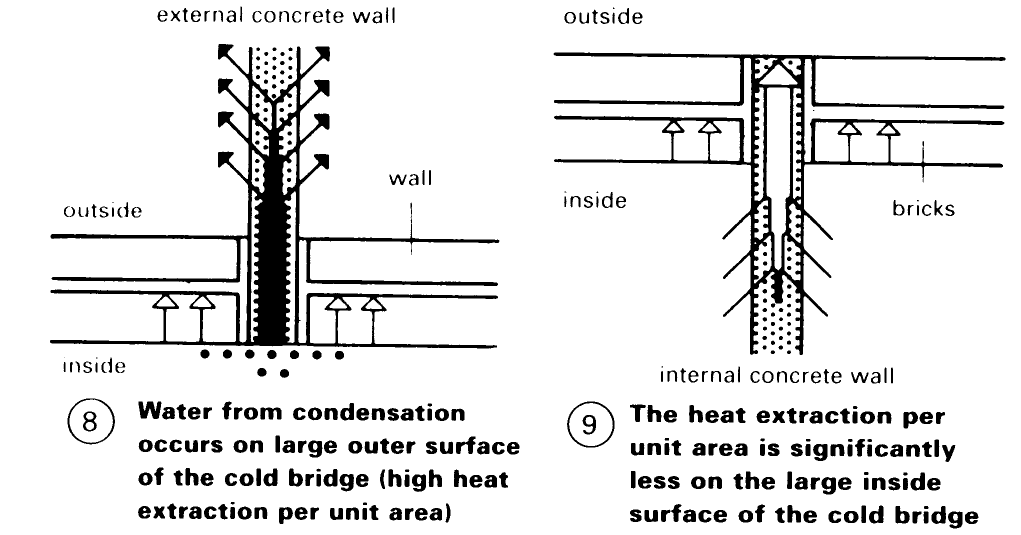

Cold bridges are places in the structure with low thermal insulation relative to their surroundings. At these places, the contribution of the air boundary layer to the resistance flow to heat increases, such that the surface temperature of the inner surface of the cold bridge reduces and condensation can occur there. The increase in heating costs due to the cold bridge, on the other hand, is insignificant, so long as the cold bridge is relatively small; this is not the case, however, for single-glazed windows which, in reality, are also cold bridges – (7).

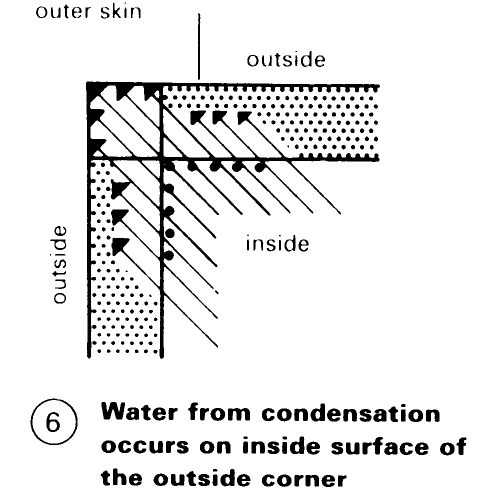

To avoid condensation on the surface of the component and its unwelcome consequences (mould growth, etc.), the temperature of the inner surface of the cold bridge must be increased. This can be achieved by either reducing the heat extraction through the cold bridge by means of an insulating layer against the 'outer cold' (increasing the thermal insulation reduces the percentage contribution of the air boundary layer to the resistance to heat flow ΣR), or increasing the heat input to the cold bridge by increasing the inner surface of the cold bridge, e.g. good conducting surroundings to the cold bridge, and/or blowing with warm air. This will result in an actual reduction in the inner surface resistance 1/a in relation to the cold bridge and hence also the contribution of the air boundary layer to the resistance to heat flow ΣR. Typical examples are shown in (8). However, a normal outer corner in a building - (6), forms a cold bridge, since, at such a point, the opposite to that shown in (9) occurs; a large heat transmitting outer surface is in combination with a small heat inputting inner surface, so that the insulation of the air boundary layer in the corners is appreciably higher than that on the surface.

For this reason, condensation and mould are often seen in the corners of walls with minimal thermal insulation.

Date added: 2023-01-05; views: 608;