Sound Conduction Through Structures

Vibrations in solid bodies, 'structure-borne sounds', are created either by sound in air, or directly, by mechanical excitation – (1) – (2).

Since the alternating mechanical forces are usually higher than any produced by fluctuating air pressure, the audible radiation is usually greater in the case of direct excitation. Frequently, resonance phenomena occur, which lead to higher audible radiation in narrow frequency ranges.

If the radiated sound remains monotonic, the cause is usually the result of direct excitation of the structure. Anti “structure-borne” sound measures must therefore seek to reduce this direct excitation and its further propagation.

Precautions to combat structure-borne sound transmission. In the case of water installations, only valves carrying inspection symbols in accordance with group I or II should be used. The water pressure should be as low as possible.

The water velocity plays a subordinate role.

Pipework should be attached to walls in accordance with good practice, with surface loading m" > 250kg/m2.

Baths and tanks should be installed on floating screed and separated from walls. Walled enclosures should be flexibly jointed to the primary walls. Wall-suspended WC fittings cause direct excitation of the structure; however, rigid fixing is unavoidable, so if necessary, elastic layers should be introduced.

Water and drainage pipes must be fixed using elastic materials and should not be in direct contact with the structural wall.

Lifts should be installed in separate shafts - (3) and joints filled with at least 30mm mineral fibre, or the top of the shaft provided with Neoprene bearing strips - (4).

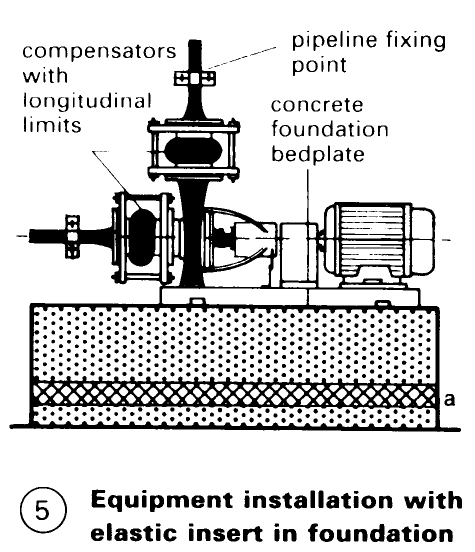

Pumps and equipment must be installed on structure- borne sound insulated foundations and elastically connected.

Compensators are subject to tensile stresses, since the internal pressure also acts on the longitudinal axis of the assembly – (5).

Rubber granulate panels are particularly suitable as insulating material for foundations, due to their high compressive strength. If required, impact sound insulating materials of mineral fibre and plastic foam can be built in. Cork and solid rubber are unsuitable, since these materials are too stiff. The more the insulating materials are compressed together under load, without being overloaded, the better is the insulating effect.

With flat insulating materials, the loading must usually be greater than 0.5N/mm2. If this cannot be guaranteed, then individual elements are required, effectively to add to the weight of the equipment.

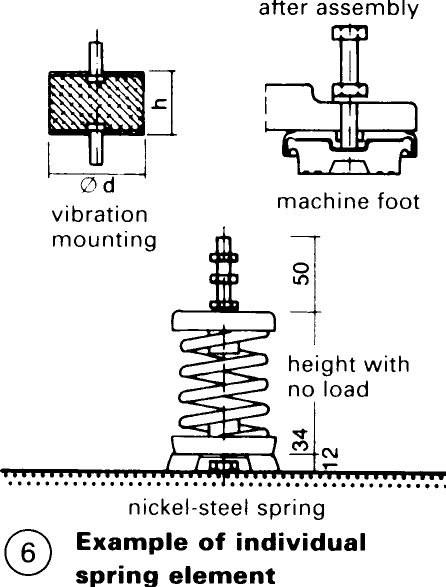

The insulating effect is also greatest here if the elements are loaded to a maximum, without becoming overloaded. The individual elements can be of Neoprene or steel (6).

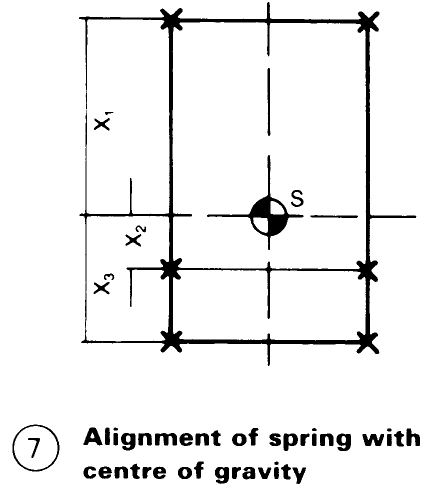

Steel springs provide the best structural sound insulation, due to their low stiffness. In special cases, air springs can be used. In the case of individual springs, attention must be paid to the centre of gravity, to ensure the elements are uniformly loaded – (7).

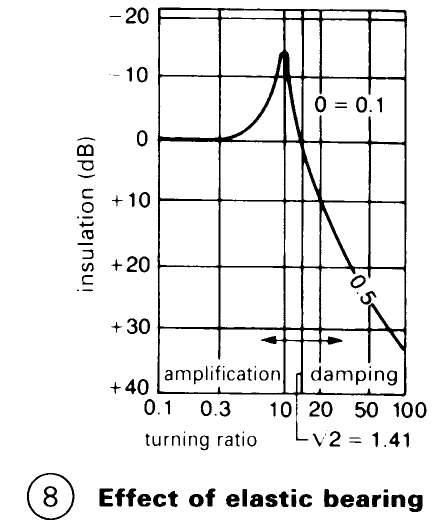

In the case of periodic excitation (e.g. due to oscillating or rotating masses), the frequency of excitation must not coincide with the natural frequency of the elastically suspended system. Large motions result from the reverberation which, in the case of elements with low damping, can lead to structural failure (8). Particularly high insulating properties may be obtained by using doubled elastic suspensions (9). Unfavourable interaction between foundations on floating layers can lead to a reduction in insulation.

Date added: 2023-01-05; views: 745;