House Dividing Walls. Impact Sound Insulation

House dividing walls constructed from wall leafs with leaf weights per unit surface area < 350kg/m2 must be separated by a cavity over the entire depth of the house; their mass should be >150kg/m2 (200kg/m2 in multi-storey residences). If the dividing wall commences at the foundations, no additional precautions are necessary; if it commences at the ground level (as for dividing walls between separate residential accommodation), the floor above the cellar must have a suspended floor or a soft springy covering. The cavity should be provided with filling material (foam panels, etc.) preferably with staggered joints; small jointing areas can reduce the sound insulation, because the structure is resistant to bending.

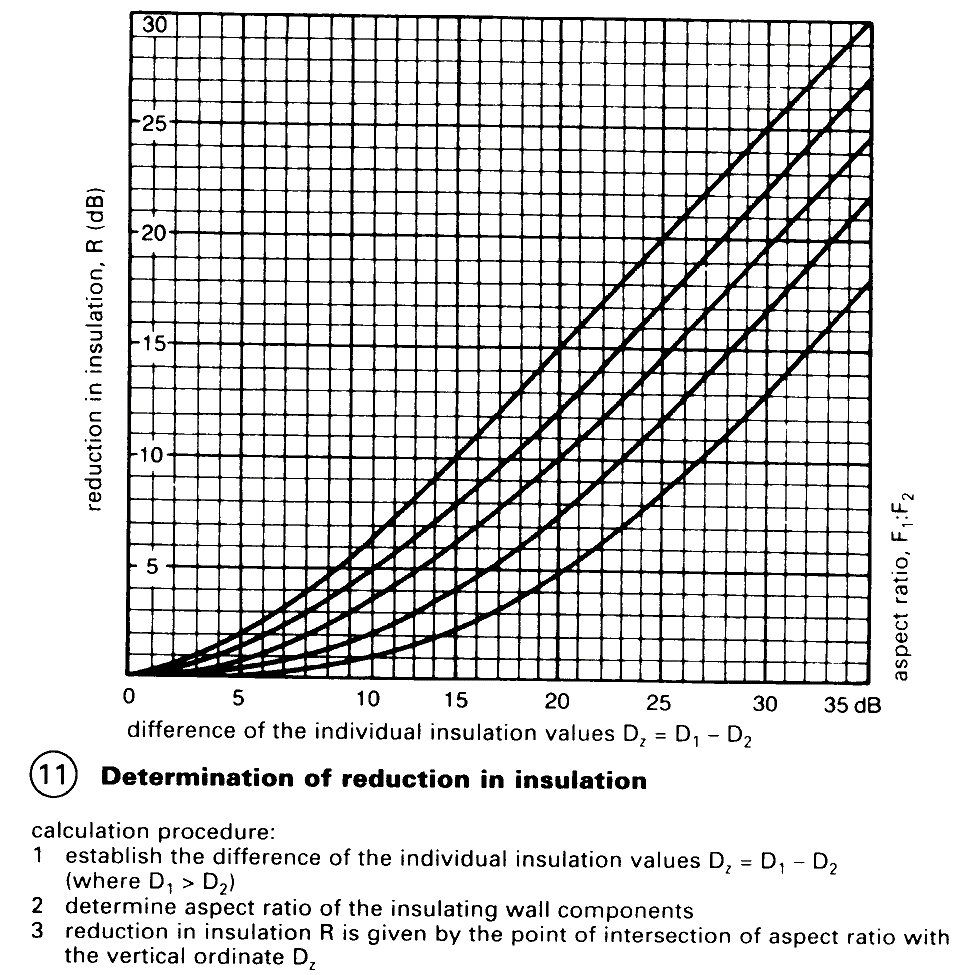

Composite walls.In this case (including any walls with areas of different sound insulation properties, e.g. with a door), the total insulation value Dg is obtained after deducting the insulation reduction R from the overall insulation value – (11).

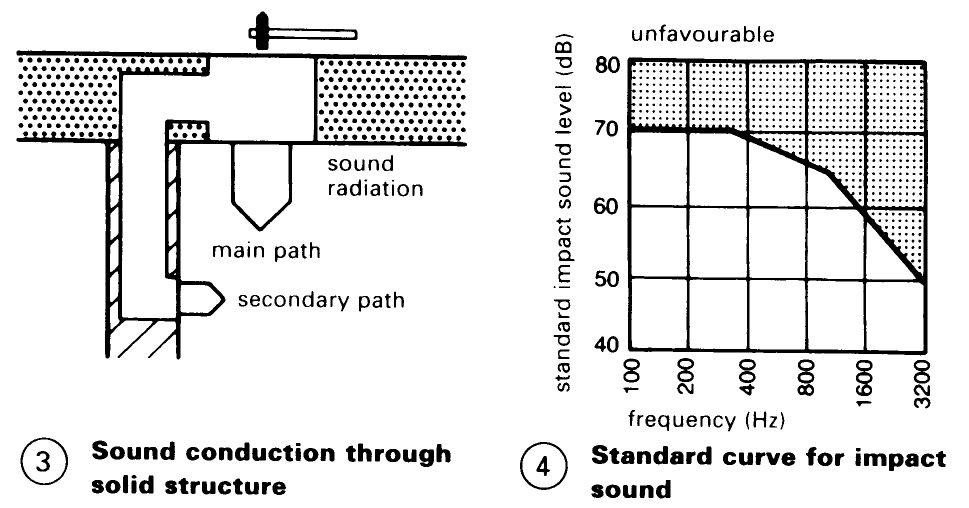

Impact sound insulation. In the case of impact sound (e.g. noise due to footsteps), the ceiling is directly excited into vibration - (3). The standard curve – (4) gives a standardised impact sound level, i.e., the maximum that should be heard in the room below when a standard Tramper' is in action above. To allow for ageing, the values achieved immediately after construction must be 3dB better than the values shown.

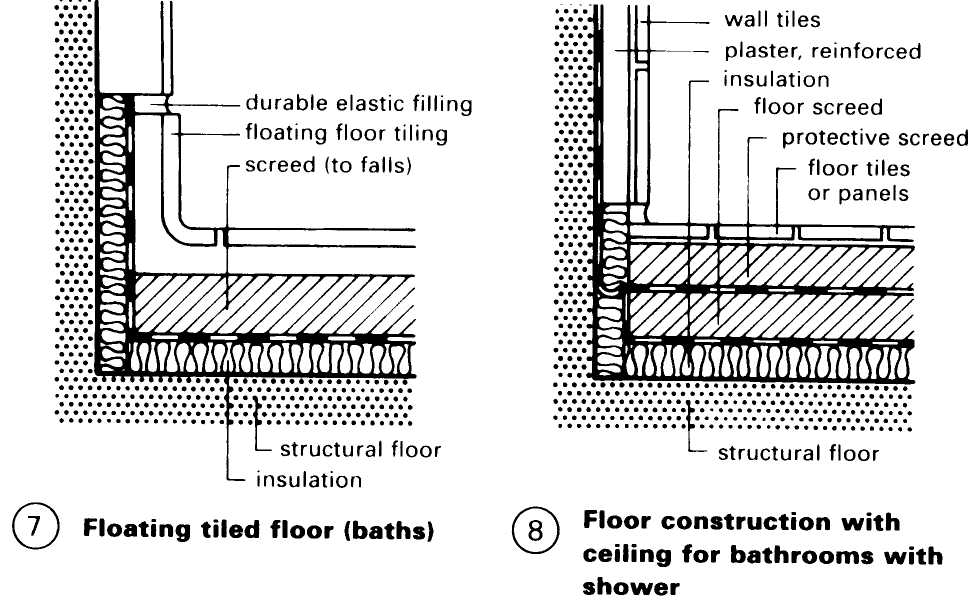

The usual form of impact sound insulation is provided by 'floating' screed, i.e. a jointless, soft, springy insulating layer, covered with a protective layer and, then, a screed of cement concrete, anhydrous gypsum or poured asphalt. This simultaneously provides protection against airborne sound and is therefore suitable for all types of floors (floor groups I and II). The edge should be free to move, and mastic joint filler with enduring elasticity should always be used, particularly with tiled floors (7), since the screed is thin and stiff, and is therefore extremely sensitive to sound bridges.

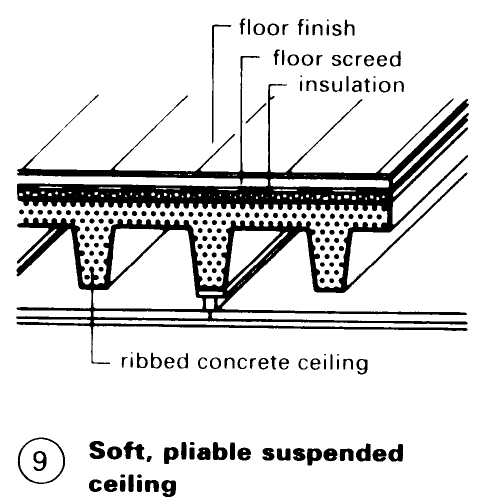

With floors whose airborne sound insulation is already adequate (floor group II), impact insulation can also be provided by using a soft, spring floor finish - (8). Floors in floor group I can be upgraded to group II by the provision of a soft, springy suspended floor (9). The degree to which this floor finish improves the impact sound insulation is judged from the improvement in dB attenuation.

Noise from services. Noise from services can occur as plumbing fixture noise, pipework noise and/or filling/emptying noises:

- For plumbing fixture noise, the remedy is provided by sound- insulated valves with inspection symbols (test group I with at most 20dB(A) overall noise level, test group II with at most 30dB(A) only permissible for internal house walls and adjoining service rooms). All installations are improved, among other measures, by sound dampers.

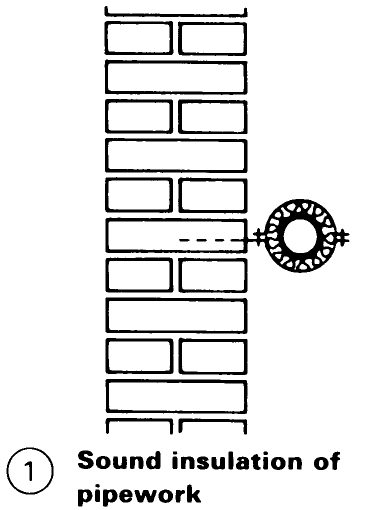

- For pipework noise due to the formation of vortices in the pipework, the remedy is to use radiused fittings instead of sharp angles, adequate dimensioning, and sound damping suspensions - (1).

- For filling noise caused by water on the walls of baths, etc. the remedy is to muffle the objects, fit aerator spouts on the taps, and to sit baths on sound damping feet (and use elastic joints around the edges).

- For emptying noise (gurgling noises), the remedy is correct dimensioning and ventilation of drain pipes.

The maximum permissible sound level due to services in adjoining accommodation is 35dB(A). Sound generating components of domestic services and machinery (e.g. water pipes, drain pipes, gas supply pipes, waste discharge pipes, lifts) must not be installed in rooms intended for quiet everyday activities (e.g. living rooms, bedrooms).

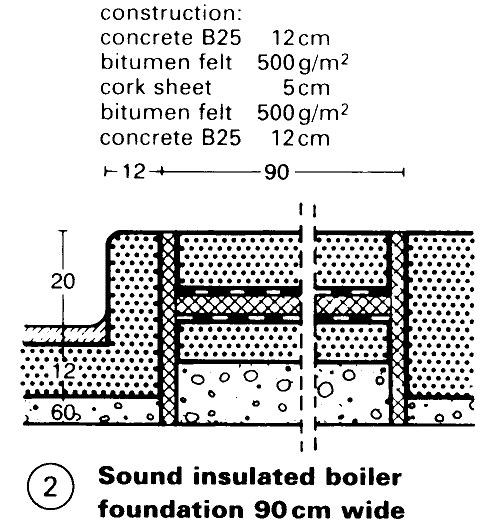

Sound insulation for boilers can be effected by sound-damped installation (isolated foundation - (2), sound-absorbing subconstruction), sound-damping hood for the burner, connection to chimney with sound-damping entry, and connection to hot pipework by means of rubber compensators.

In ventilation ducts of air conditioning systems, noise from sound transmission is reduced by means of so-called telephonic sound dampers; these comprise sound-absorbing packings, between which the air flows. The thicker the packing, the lower the frequencies which are covered. The ventilation ducts themselves should also be sound insulated.

Sound absorption. In contrast to sound insulation, sound absorption does not usually reduce the passage of sound through a component. It has no effect on the sound which reaches the ear directly from the source; it merely reduces the reflected sound.

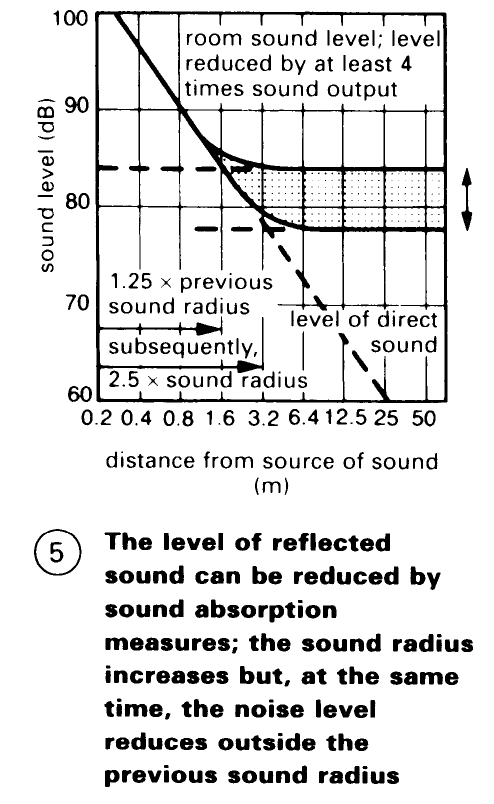

Although the direct sound diminishes with distance from the source, the reflected sound is just as loud, or louder than the direct sound, at a distance greater than the 'sound' radius about the sound source - (5). If the reflection of sound is reduced, then the level of the reflected sound is reduced outside the original 'sound' radius, while the sound radius itself increases. Nothing changes within the original sound radius.

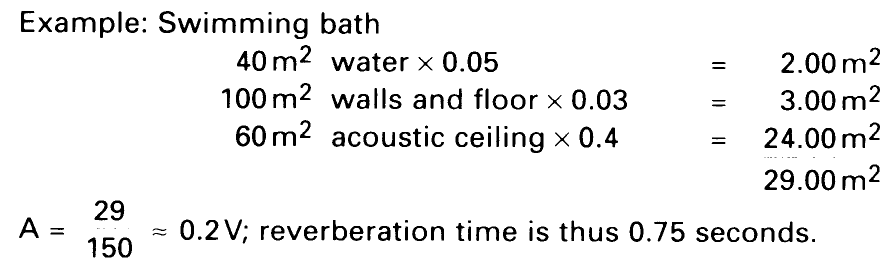

The sound absorption capability of a room is expressed in m2 equivalent sound absorption, i.e. the ideal sound absorbing surface that has the same absorption capability as the room itself. For a reverberation time of 1.5 sec. - ideal for private swimming baths, etc. - the equivalent sound absorption surface A must be 0.1 m2 for every m3 of room volume v (the sound radius would then be only 1.1 m in a room 6 x 10 x 2.5m) and twice as large to achieve half the reverberation time.

Date added: 2023-01-05; views: 629;