Garage/Warehouse Doors. Locking Systems

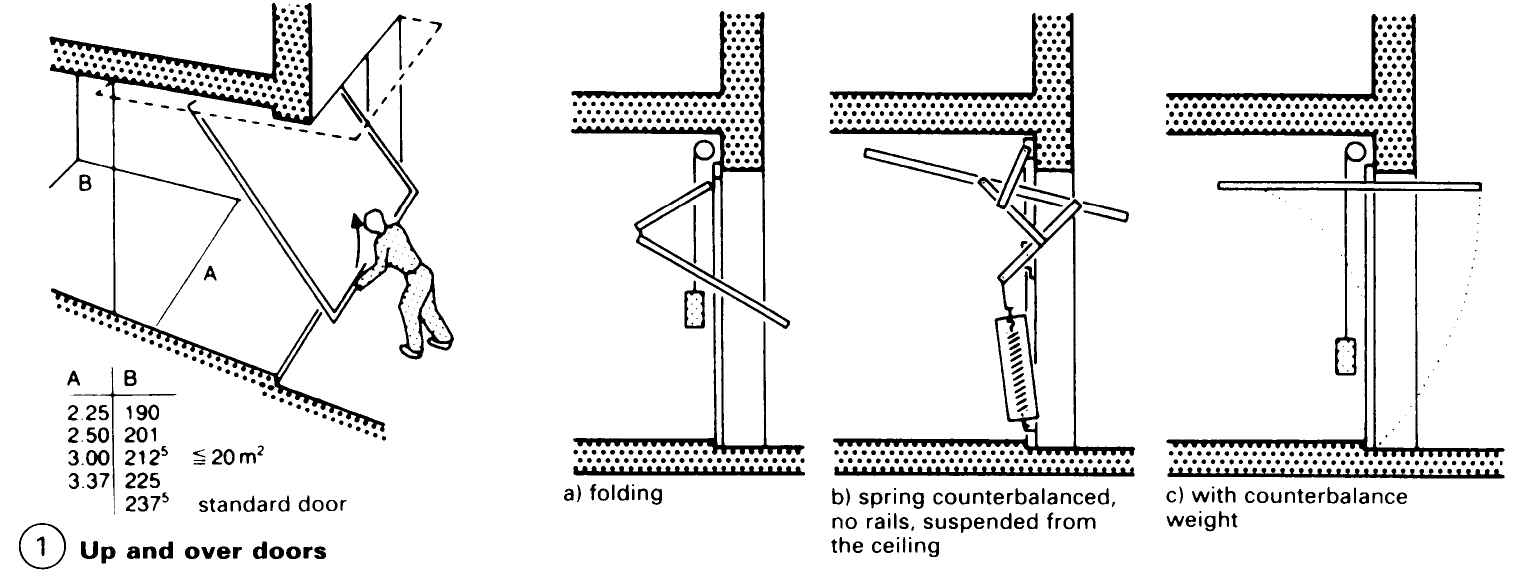

Up and over doors can be used for garages and similar installations - (1). They can be folding doors, or doors with a spring counterbalance or a counterbalance weight. They can have a single or a double skin, and be solid, partially glazed or fully glazed. They can have wooden panels, or be made of plastic, aluminium or galvanised sheet steel. The largest available dimensions for access purposes are 4.82m x 1.96m, and the maximum panel area is approx. 10m2. Up and over doors are also available in arched segments. They are easy to operate since the door drive is mounted on the ceiling and controlled by radio.

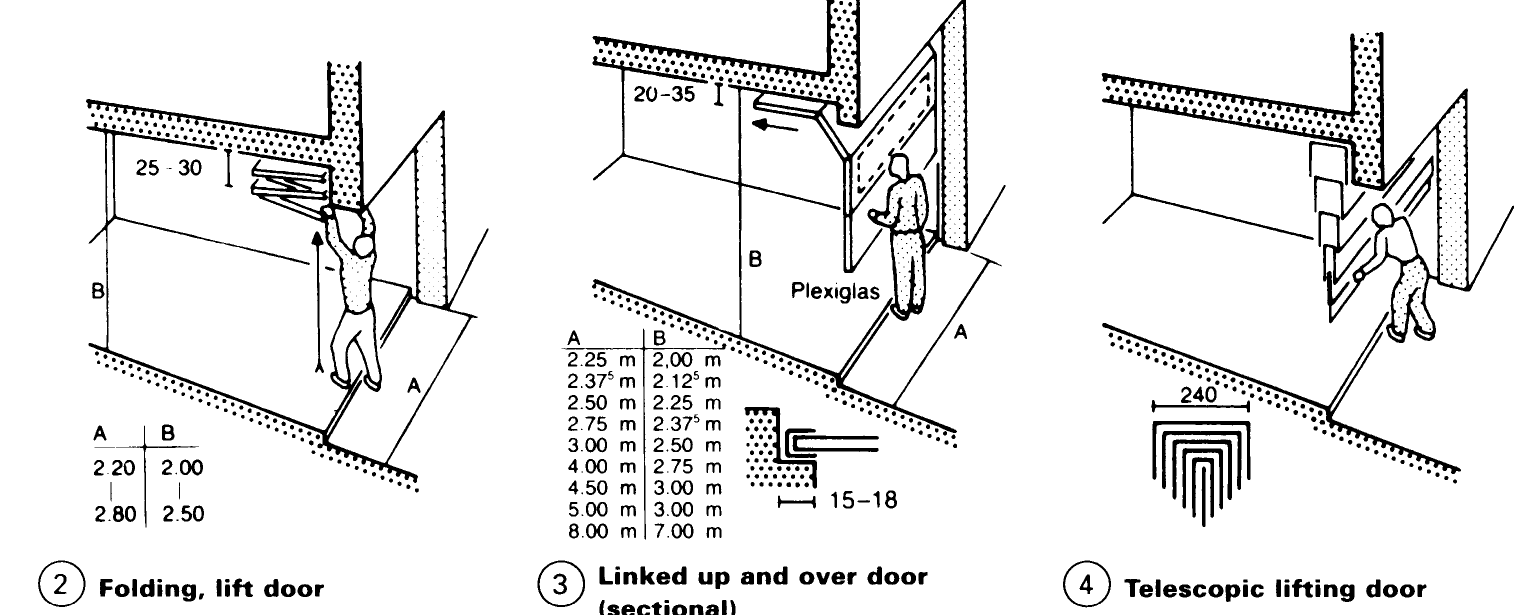

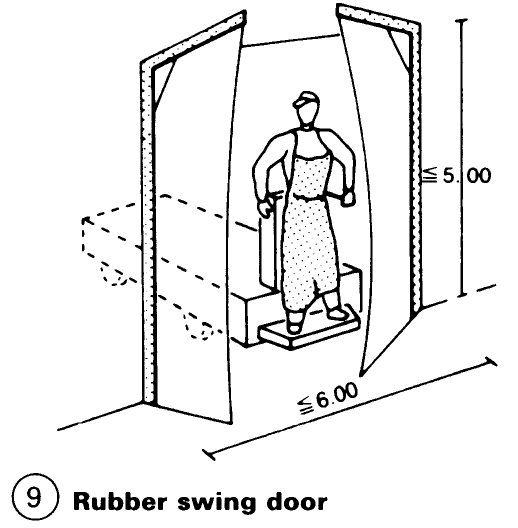

Also available are lifting folding doors - (2), sectional doors - (3), telescopic lifting doors - (4) and roller shutter doors made of aluminium - (5) which are completely out of the way when open. Single - or multiple-skin doors can be used for industrial, transport and workshop buildings. The maximum available size is 18m wide and 6m high. These doors can be activated by a ceiling pull switch, a light barrier, an induction loop or remote control (either electric or pneumatic), or contact pads.

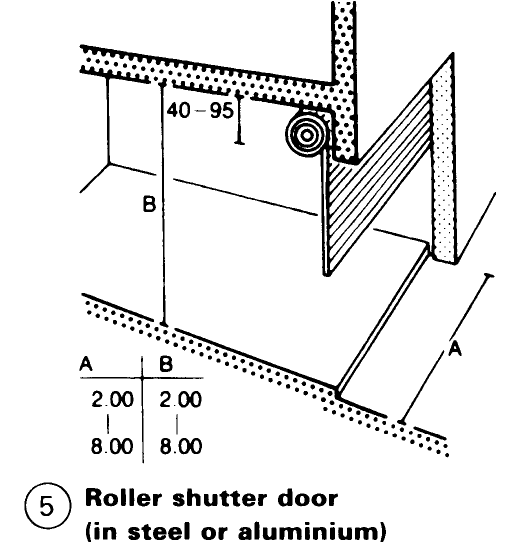

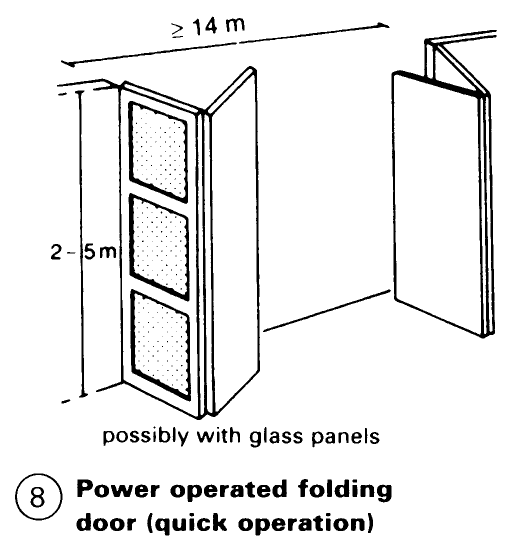

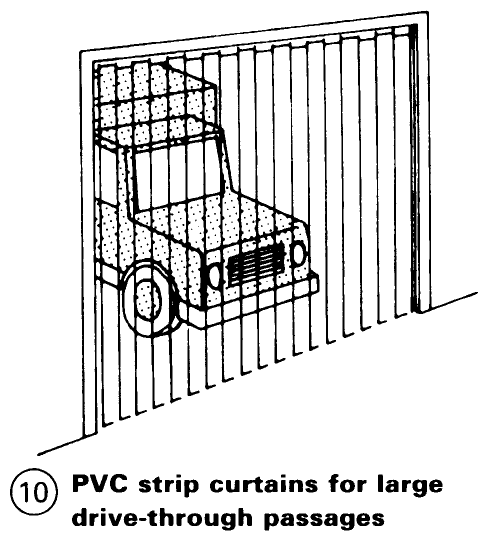

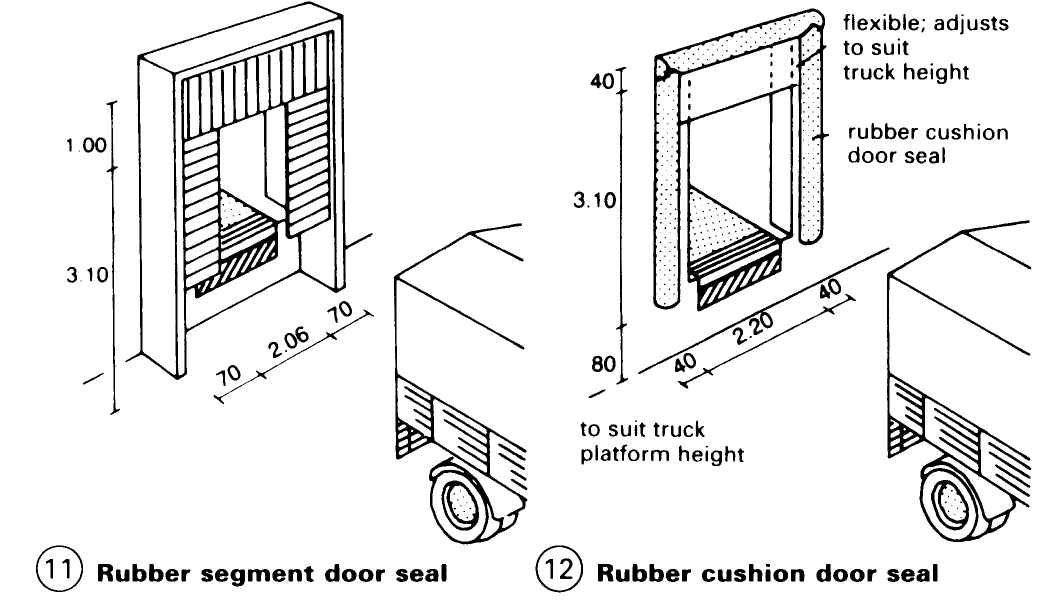

Drive-through doors should be power-operated for speed (8). Rubber swing doors - (9) and single-layer clear PVC are resistant to abrasion and impact, and PVC strip curtains are also available — (10). Rubber sections which serve as door seals and rubber cushion seals are available for loading and unloading from docks and in and out of heated storage depots. They give protection from the effects of the weather during these operations – (11), (12).

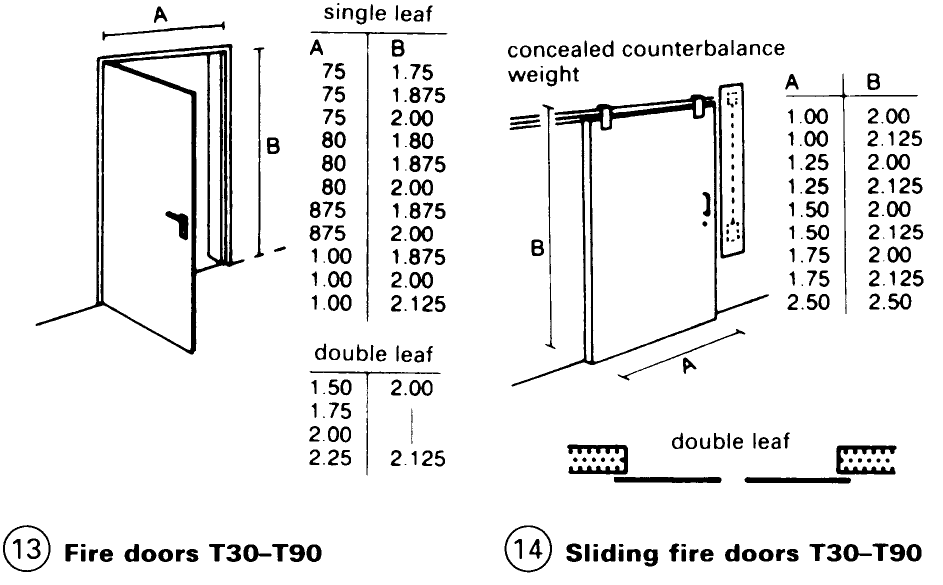

Fire protection doors T30-T90 can be single- or double-leaf – (13). Sliding fire protection doors are also available – (14). Any movable fire-resistant barrier, such as sliding, lifting or swing doors, must be able to operate independently of the mains electricity supply. In the event of fire, they must close automatically.

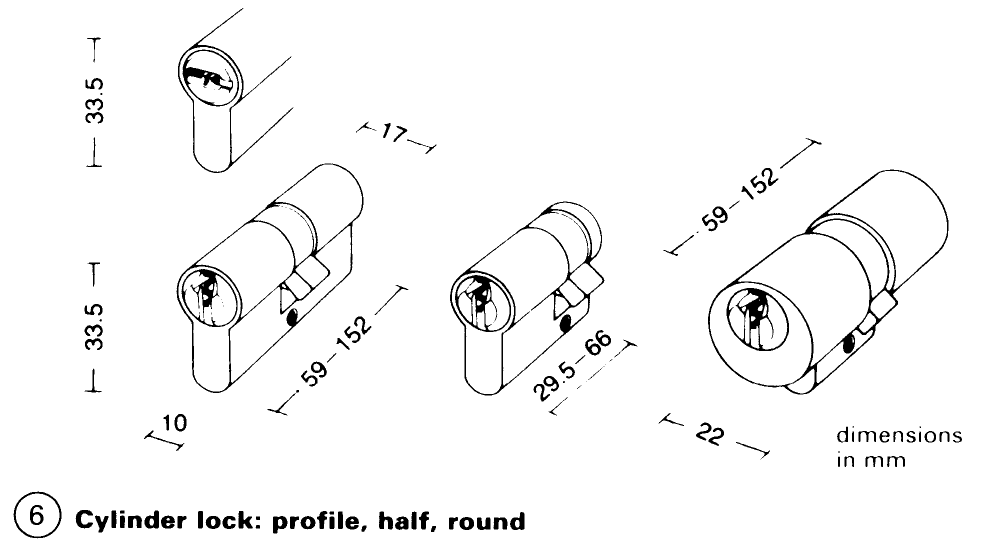

Locking Systems. Cylinder locks offer the greatest security, for it is virtually impossible to open them with tools. The cylinder lock developed by Linus Yale is very different from other locking systems. There are profile, oval, round and half cylinder locks. Cylinder locks are supplied with extensions as necessary on one or both sides, increasing in increments of 5mm, to suit the thickness of the door - (6).

During the planning and ordering phase for a locking system, a locking plan is drawn up which includes a unique security certificate. Replacement keys are only supplied after production of this document.

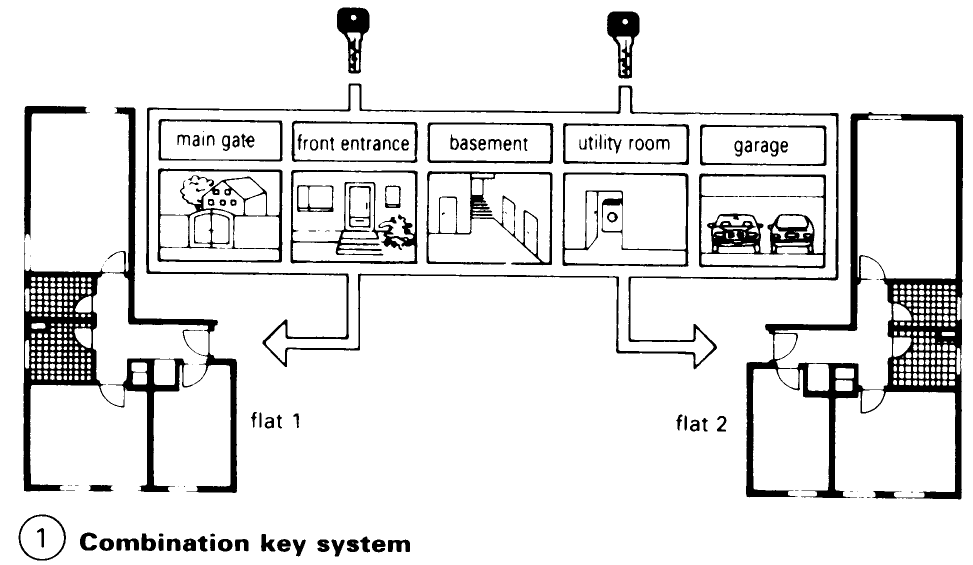

Combination key systems. With a combination key system, the key of the entrance door to each flat also opens all doors to shared facilities as well as shared access doors, e.g. courtyard, basement or main front door. This is suitable for houses with multiple family occupancy or estate houses - (1).

Master key systems. In a master key system, a principal pass key opens all locks throughout the complete system. This is suitable for single family occupancy houses, schools and restaurants.

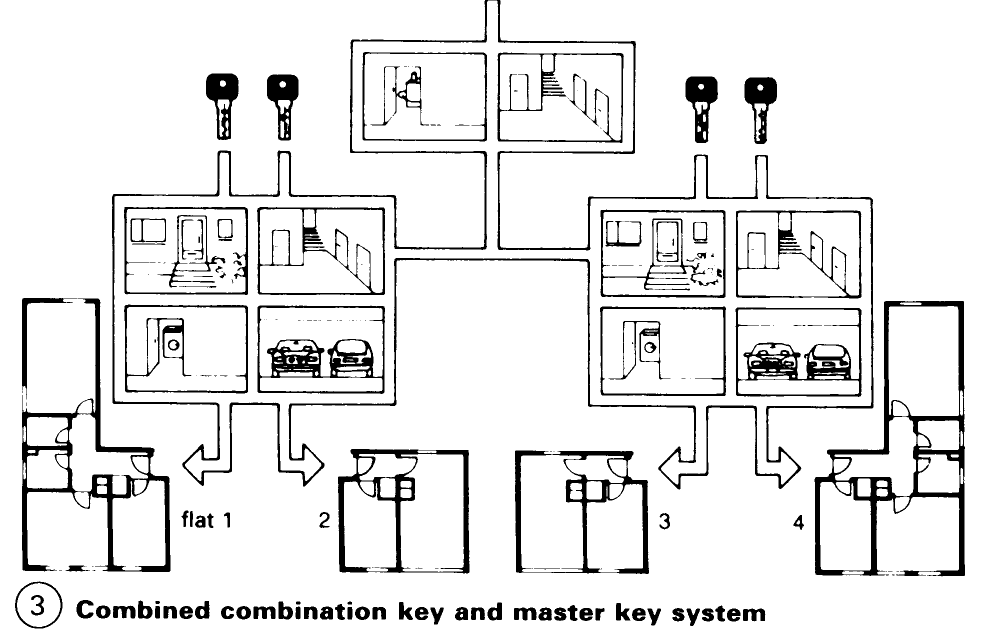

Central key systems. With a central key system, several combination key systems are combined. This is suitable for blocks of flats - (3). Separate keys unlock the front door to each flat and to all shared facilities. In addition, there is a master key which unlocks all the shared doors in the blocks.

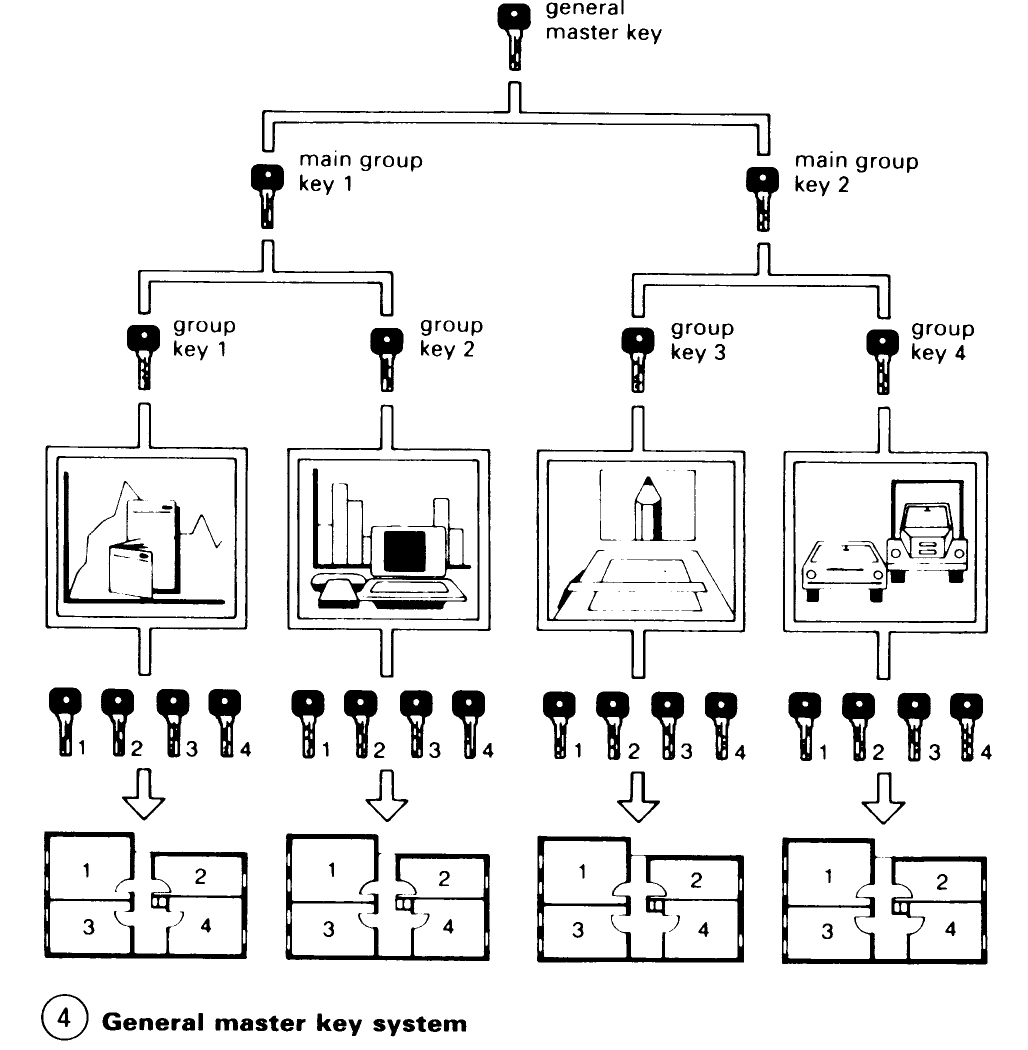

General master key systems. A general master key system consists of multiple master key systems. The general master key allows one person access to all rooms. It is possible to subdivide areas by using main and group keys. Each cylinder has its own individual lock and, with the exception of the correct master (or pass) key, can only be opened with its own key.

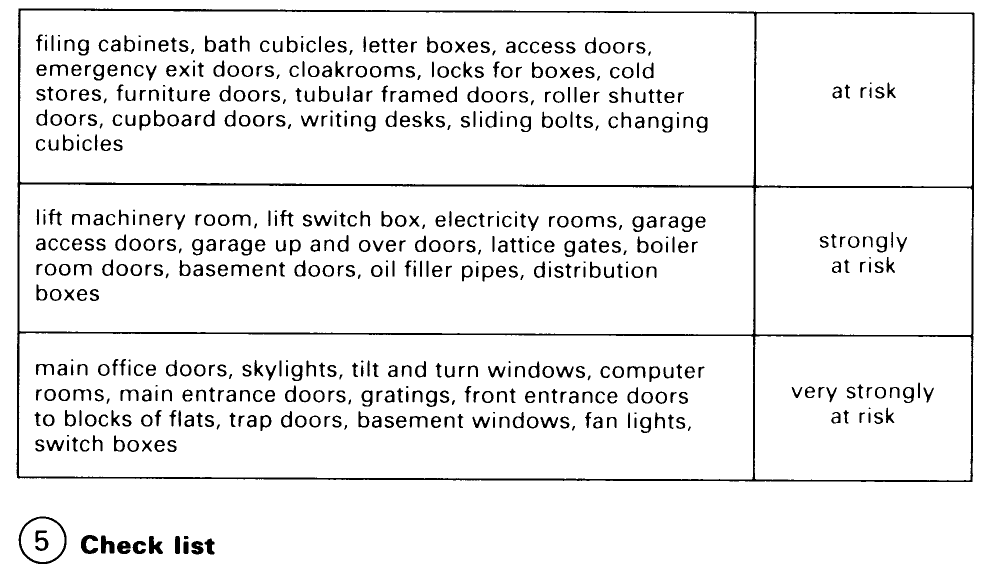

This system is suitable for factories, commercial premises, airports and hotels – (4). Vulnerable points which should be taken into account during the planning stage are set out in - (5).

Date added: 2023-01-01; views: 746;