Sound Damping. Plant Rooms. Air Conditioning Systems For Large Offices

Sound dampers are provided in air ducts to reduce noise from installed machinery into the air-conditioned rooms. The length of these in the direction of air flow is 1.5-3m, depending on the damping to be achieved. The design may embody baffles made from non-combustible material, e.g. moulded fibre boards or from sheeting with a rockwool filling. The requirements for sound insulation in building construction should be observed.

Ducts and air outlets and inlets are in galvanised steel sheet, high-grade steel or fire-resistant fibre board or similar. Ideally, the cross-section should be square or round, or rectangular with an aspect ratio of 1:3. Regular servicing is necessary, and the requirements for fire protection of ventilation systems must be observed.

Masonry or concrete built ducts are more economical than sheet construction for large floor or rising ducts. Masonry ducts dampen noise better than concrete. The insides should be smoothly plastered and have a washable surface coating. Air entry ducts should be provided with lightweight insulation only, so that heat retention is avoided. The duct cross-sections should be large enough for cleaning (soiling impairs the condition of the air). So, the floor air-exhaust ducts should be equipped with drainage pipes or channels with sealed screwed connections and the air ducting should have adequate access openings for cleaning purposes.

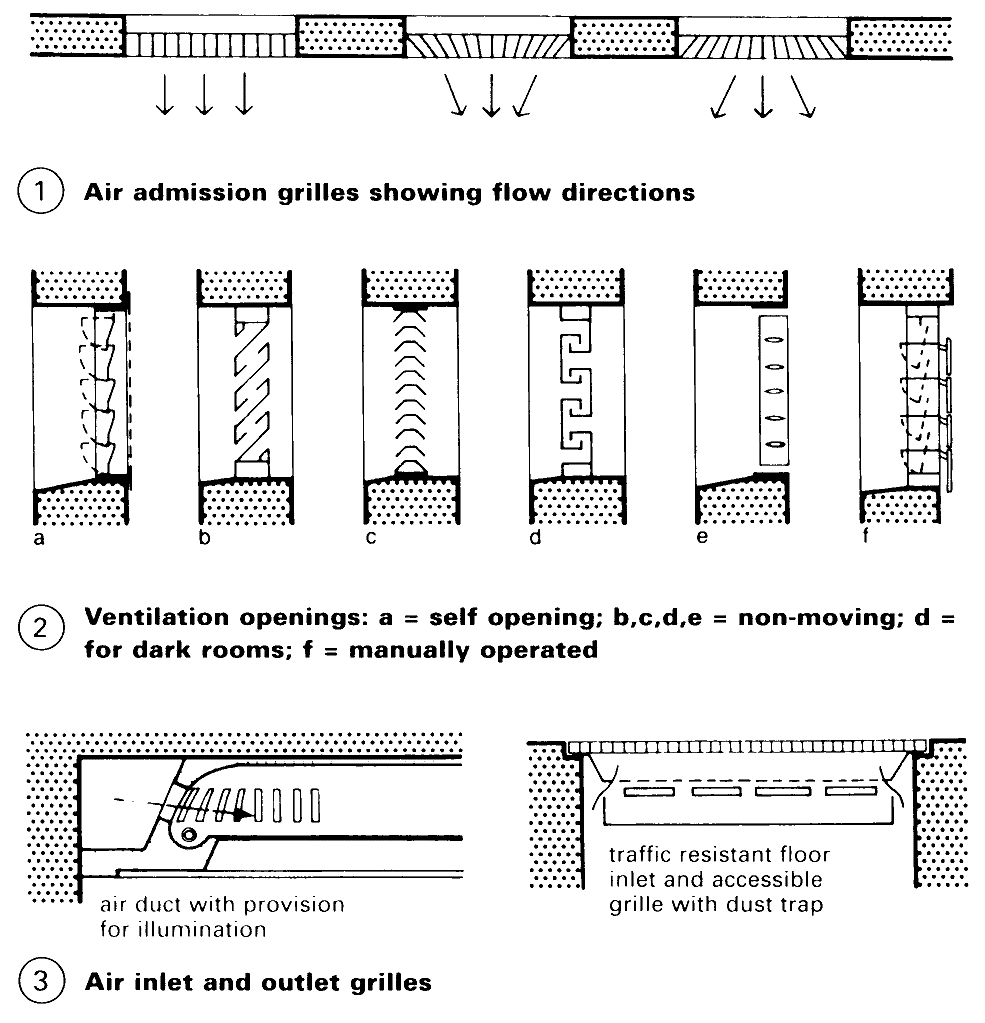

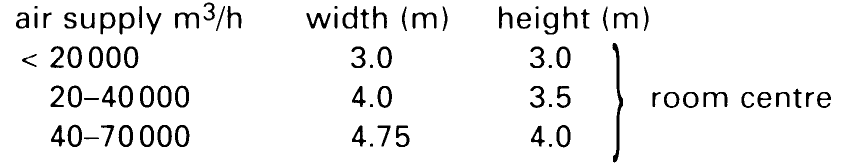

Cement fibre ducts (asbestos-free) are suitable for moist, non-acid containing air and plastic ducts for aggressive, gaseous media. Inlet and outlet gratings should not be sited in accessible floor areas (except in industrial construction and electronic data processing rooms). Air outlets are crucial for the distribution of air in rooms; the flow should be directed horizontally and vertically. Grilles for air inlets and outlets should be designed from an air conditioning standpoint, but should also be easy to clean - ideally made from stove enamelled sheet. (1) – (3).

The introduction of air into offices should, when possible, be at a window (point of most pronounced passage of cold and heat). Air removal should be on the corridor side. For theatres, cinemas and lecture rooms, admit air under the seats, and remove through the ceiling. This method depends on the shape and usage of the room.

Plant rooms. Air conditioning and ventilation systems should be considered during preliminary planning, as they have a major influence on building design and construction. Plant rooms should be as near as possible to the rooms to be air-conditioned, provided this is acoustically acceptable, and have good accessibility. The walls should be of masonry, plastered, with a washable coating, preferably tiled.

Floor drainage should be provided in all compartments, and have traps and airtight removable covers. Where plant rooms are above other rooms, watertight floors should be provided. External walls need insulation and vapour barriers, to avoid damage by condensation. The extra floor loading for machinery in a plant room can be 750-1500kg/m2, plus the weight of the walling of the air ducting. In situations where there are extremely high requirements for noise and vibration reduction, consideration should be given to flexible mounting and isolating a plant room as a 'room within a room'.

Space requirements for air conditioning equipment are very much dependent on the demand for air filtering and sound damping. In narrow, long floor shapes, the compartments can be arranged in sequence, one after the other.

- Simple industrial conditioning systems: approx. 12 m long

- For full air conditioning systems: approx. 16-22m long

- For air extract systems: approx. 4-6m long.

Width and height (clear space) for industrial and full air conditioning system plant rooms:

An additional 1.5-2m should be allowed for assembly and maintenance access. In the case of large installations, for heating and air conditioning distribution systems, allowance should be made for common maintenance access and space for the control panel.

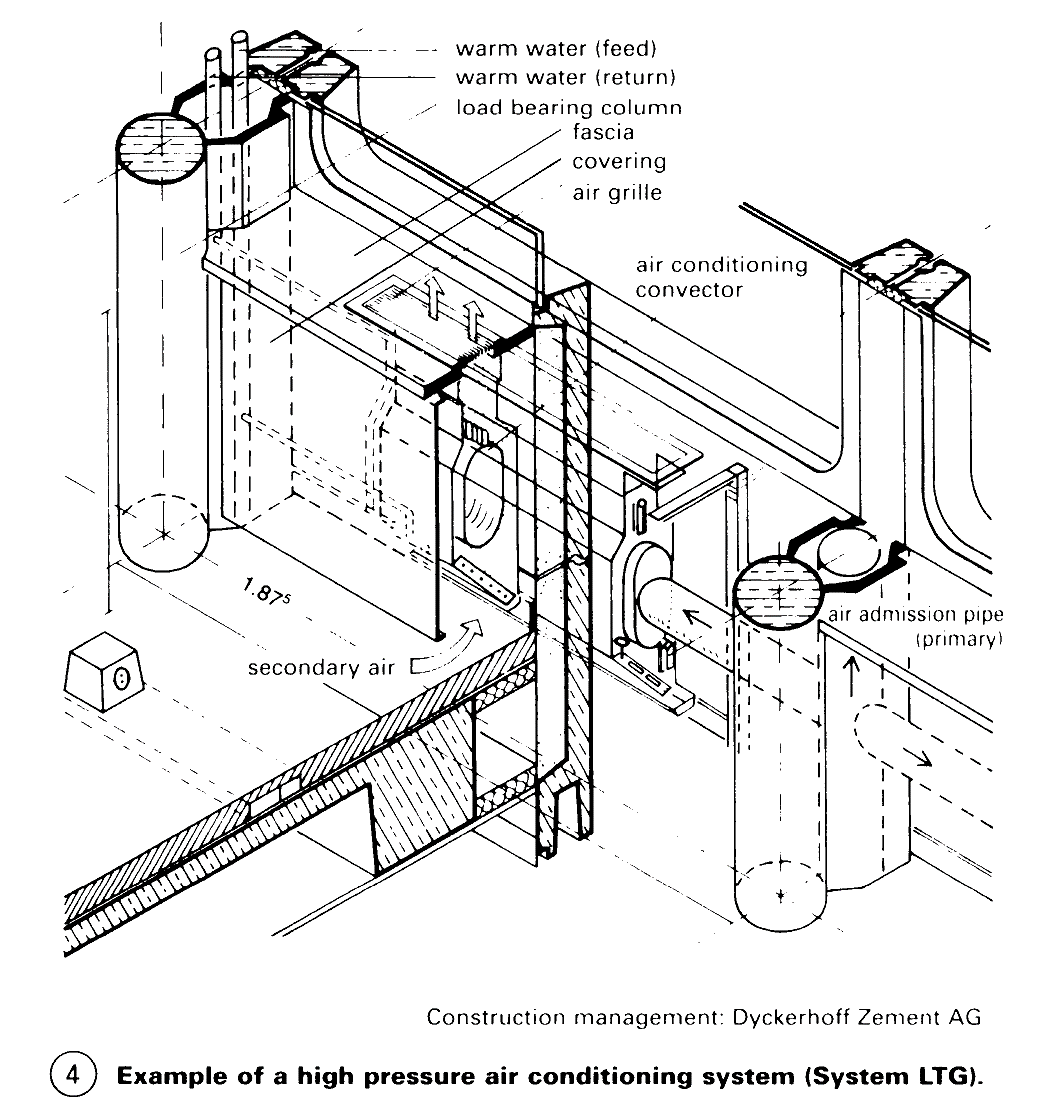

Air conditioning systems for large offices. It is useful to use several conditioning systems for large and open planned rooms. An isolated conditioning zone can be installed in the fagade area (high-velocity systems) and a separate area for the internal zone, with low pressure or high velocity systems - (4).

Date added: 2023-01-05; views: 575;