Cooling and Refrigeration of Poultry and Game. Room Cooling, General

Large game (red deer, roe deer, wild boar) must be drawn before freezing, but this is not necessary for small game (hare, rabbit, game birds). Freezing takes place before plucking, with the game free-hanging; storage being in stacks on gridded floor panels. There should be plenty of air movement during freezing, but little during storage. These numbers of game can be stored per square metre of floor area (3[t]m high): approx. 100 bares, or 20 roe deer, or 7-10 red deer. The air humidity should be approx. 85% at -12°C.

Domestic poultry should not be frozen and stored with game, as the fat content of the former requires a lower temp, and is sensitive to the smell of game. The cooling of poultry takes place at 0°C and at 80-85% relative humidity, with the birds suspended on frames, or alternatively, in iced water; storage at 0°C and 85% relative humidity, with a storage duration of approx. 7 days. Freezing at approx. -30--35°C, storage at around -25°C and 85-90% relative humidity. The freezing time for a chicken is approx. 4 hours at an air velocity of 2-3m/sec. Deep freezing, using the cryovac method, takes place in vacuum latex bags. Young chickens will freeze through in 2-3 hours. Storage duration is approx. 8 months at -18°C. To prevent rancidity, the poultry is protected by wrapping in water vapour tight polyethylene film.

Brewery products. Malt floors: 8-0°C

Cooling requirement per m2 of floor area: 5000-6300 kJ/day

Fermentation cellars: duration is 8-10 days at 3.5-6°C

Cooling requirement: 4200-5000kJ/day per m2 of floor area

Cooling requirement for the fermentation vat cooling:

500-630kJ per hi fermented wort per day

Storage cellar: -1.0°C to +1.5°C; cooling requirement approx. 20-25Wm3, related to the empty room, or 2.5-3kcal/h per hi of storage capacity

Installed cooling power: approx. 2.1-2.3Whl yearly output

Room cooling, general. From the viewpoint of reserves and safety, the cooling system is designed to have a higher performance than the calculated cooling requirement. It is assumed that the cooling system will operate for 16-20 hours per day in cooling and freezing rooms; in individual cases, e.g. for efficient utilisation of electrical tariffs, the period may be even shorter. In meat cold storage rooms, the cooling power should not be too high, so that during periods of reduced cooling requirements, adequate operating durations and the required throughput of air in the room will still be guaranteed.

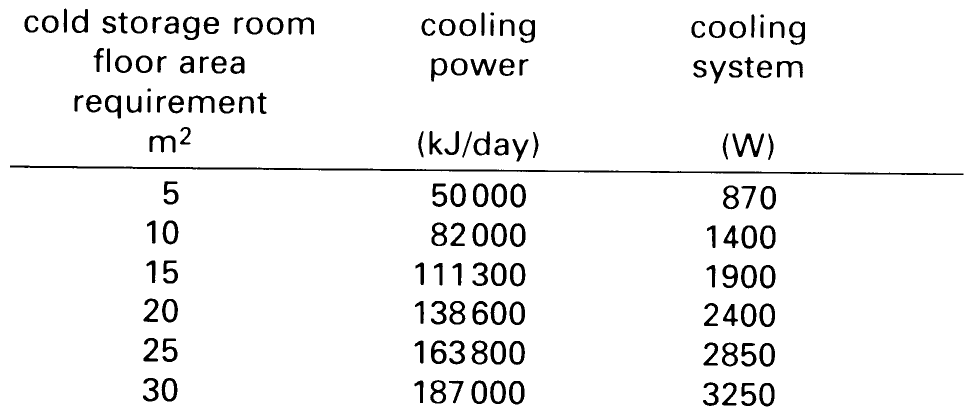

In small commercial cold storage rooms with a temperature of approx. 2-4°C and a product throughput of 50kg/m2 per day, the following table serves as a reference to determine the cooling requirement and the requisite power of the cooling system.

The following figures can be used for further calculations: Cold storage rooms with multi-storey construction: 5000-8400 kJ/day/m2

Cold stores of single-storey construction: 1050-1700 kJ/day/m2

Storage capacity per m2 of floor area - hanging storage - after reduction of approx. 15-20% for gangways: mutton 150-200kg (5-6 items), pork 250-300kg (3-3.5 whole, 6-7 sides), beef 350kg (4-5 quarters of beef).

Per running metre - low hanging rail: 5 halves of pork or 3 quarters of beef or 2-3 calves

Distance from centre to centre of rails (low rail): approx. 0.65 m, height to centre of rail: 2.3-2.5 m

Distance from rail to rail (high rail): 1.20-1.50m with free passage way; height with tubular track: 3.3-3.5m

Per running metre of high rail: 1-1 5m (2-3 sides of beef), depending on size.

Estimate of cooling requirements for meat: rapid cold storage room, 21000-31500kJ/m2/day; most rapid cold storage room, 4200kJ/m2/hour.

Storage room for frozen meat - storage capacity per m3 of room volume: frozen mutton, 400-500kg; frozen pork, 350-500 kg; frozen beef, 400-500 kg Standard stacking height: 2.5m.

Fats become rancid with the passage of time under the effects of light and oxygen, so that the storage duration is limited.

Meat curing room: temperature 6-8°C Cooling requirement per m2 of floor area: 4200-5000kJ/day.

Brine in curing vats absorbs moisture from the air. One railway goods wagon of 15000kg loaded weight can accept approx. 170 hanging sides of pork over a floor area of 21.8m2.

Date added: 2023-01-05; views: 612;