Piston Cooling. Piston Designs

Spray Cooling. One version often found is a nozzle located at the lower end of the cylinder, through which motor oil is sprayed onto the inside contours of the piston. The cooling effect is dependent upon the volume of cooling oil and the surface area available for heat transfer. In this way temperature reductions of up to 30°C can be attained at the first groove and the boss. A simpler version is a bore through the big-end eye, which is provided with oil from the conrod bearing lubrication system. In addition to a lesser cooling effect, the part of the stream of oil that meets the cylinder running surfaces provides better lubrication, which in turn offers greater security against fuel friction.

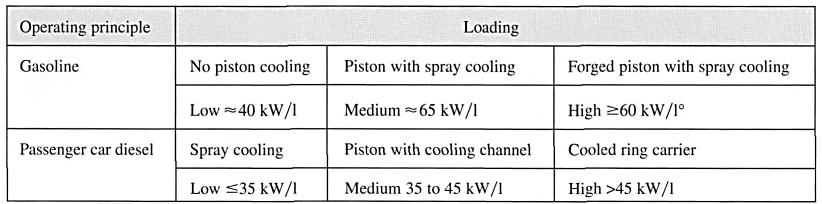

Pistons with Cooling Oil Cavities. A more complex but more effective option for piston cooling is to provide cavities in those areas at the piston head and the ring grooves that are subjected to severe thermal loading. An annular cooling channel is supplied with oil, through a feed opening, by a spray nozzle; after taking on heat (ΔT up to about 40°C) the oil passes through a discharge opening on the opposite side of the piston and returns to the oil sump. The recommended specific masses for cooling oil come to about 5 kg/kWh. A cooling channel cast directly at the ring carrier ("cooled ring carrier") provides ideal effectiveness in regard to groove cooling. Figure 7-11 shows the typical application ranges for various piston designs.

Fig. 7-11. Survey of cooling variants

Piston Designs. Ongoing piston development has produced a large number of designs, the most important of which, having proven themselves in practice, are presented here. In addition, new directions for development are being pursued, for example, pistons for engines with an extremely low profile, pistons made of composites with local reinforcing elements, or pistons with a variable compression height, which permit variable compression ratios.

Modern gasoline engines use lightweight designs with symmetrical or asymmetrical oval skirt shapes (cam ground pistons) and, if indicated, differing wall thicknesses for the contact side and the opposite side. These piston designs are distinguished by optimized weight and particular flexibility in the center and lower skirt areas. It is for the reasons mentioned here that the regulating piston is becoming less and less common. Older designs are also discussed briefly in the interest of completeness.

Pistons with Strip Inserts to Regulate Thermal Expansion, for Installation in Gray Cast Iron Engine Blocks. The primary objective in regulating piston design and for many inventions in this sector was and is the effort to reduce the relatively large differences in the coefficients of thermal expansion between gray cast engine blocks and aluminum pistons. Known solutions range from Invar strip pistons to the Hydrothermik or Hydrothermatik pistons.

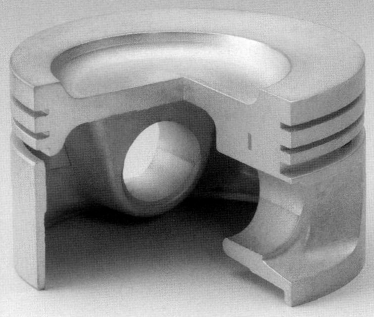

Hydrothermik Piston. Hydrothermik pistons, Fig. 7-12, are designs with a skirt profile formed in accordance with hydrodynamic aspects. They are installed in gasoline engines for passenger cars. The pistons are slotted at the transition from the piston head to the skirt, at the level of the third groove. These pistons are characterized by particularly smooth running and long service lives. The strips cast in place between the skirt and the wristpin bosses, made of nonalloyed steel, in conjunction with the lightweight metal that surrounds them, form regulation elements that reduce the thermal expansion of the skirt in the direction that is important for guidance within the cylinder.

Fig. 7-12. Hydrothermik piston

Hydrothermatik Pistons. Hydrothermatik pistons, Fig. 7-13, operate on the same expansion regulation principle as the Hydrothermik pistons. In the Hydrothermatik piston, the transition from the head area to the skirt is not slotted; the transitional cross sections are dimensioned so that, on the one hand, the flow of heat from the piston head to the skirt remains relatively unhindered while, on the other hand, the effect of the steel strips, because of the connection of the skirt with the rigid head section, is not affected in any essential way.

Thus, this piston design joins the high strength of the non-slotted piston with the advantages of the design using regulation strips. The Hydrothermatik piston is also suitable for use on naturally aspirated diesel engines.

Fig. 7-13. Hydrothermatik piston

To extend the service life and to reduce wear the pistons used in diesel engines are fitted with a ring carrier (groove insert) made of austenitic cast iron.

Asymdukt Piston. The Asymdukt piston, Fig. 7-14, is a modern piston design distinguished by very low weight, optimized support, and a boxlike, oval-shaped skirt section. It is excellently suited for use in modern gasoline engines for passenger cars. It is suitable both for aluminum engine blocks and for gray cast engine blocks. With the flexible skirt design the differences in thermal expansion between the gray cast block and the aluminum pistons can be excellently compensated within the elastic range. The pistons may be either cast or forged. The forged version is used above all in high-performance sport engines or in heavily loaded, turbocharged gasoline engines.

Fig. 7-14. Asymdukt piston

Piston for Race Cars. These are always special designs, Fig. 7-15. The compression height (KH in the illustrations) is very short, and the piston as a whole is superbly optimized for weight. Only forged pistons are used here. Weight optimization and piston cooling are decisive criteria for the design of these pistons. In Formula 1 engines' specific output of more than 200 kW/1 and engine speeds exceeding 18000 rpm are common. The service life of the pistons is matched to the extreme operating conditions.

Fig. 7-15. Formula 1 piston, forged

Pistons for Two-Cycle Engines. In the two-cycle piston, Fig. 7-16, the thermal loading is particularly high because of the more frequent exposure to heat; there is one ignition event for each rotation of the crankshaft. In addition, it has to close or open the inlet and outlet channels in the cylinder during its upward and downward strokes. This means that it has to control the exchange of gases. The result is severe thermal and mechanical loading.

Fig. 7-16. Piston and cylinder for a two-cycle engine

Two-cycle pistons are equipped with one or two piston rings and, with regard to their outward design, can vary from the open "windowed" piston to a version with a full skirt. This depends upon the design of the overflow channels (long or short channels). In this case the pistons are normally manufactured from the MAHLE 138 supereutectic Al-Si alloy.

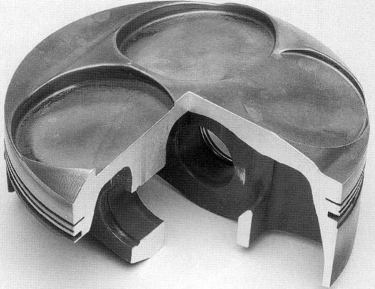

Ring Carrier Piston. In the case of ring carrier pistons, Fig. 7-17, introduced to mass production as early as 1931, the topmost ring groove and, in some cases, the second ring groove lie in a so-called ring carrier or groove insert that is joined permanently with the piston material by a metallic bond.

Fig. 7-17. Ring carrier piston

The ring carrier material is made of a nonmagnetic cast iron with a coefficient of thermal expansion similar to the material used for the piston itself. This material is particularly resistant to friction and impact wear. The groove that is most seriously endangered and the piston ring seated in it are effectively protected in this way against excessive wear. This is particularly advantageous where high operating temperatures and pressures are encountered, such as those found in diesel engines in particular.

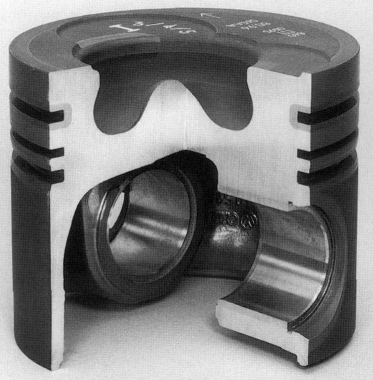

Cooled Pistons. There are various types of cooling channels and cooling spaces to achieve particularly effective heat dissipation in the area near the combustion chamber and to combat the elevated temperatures resulting from performance increases. The cooling oil is generally delivered through the so-called fixed nozzles mounted in the crankcase.

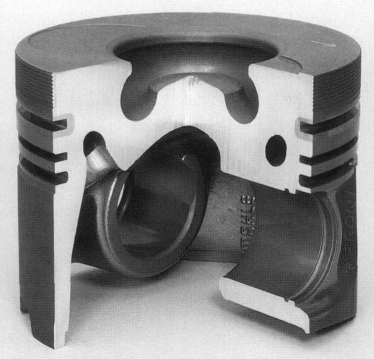

In the cooling channel piston, Fig. 7-18, the ring-shaped cavities are created by inserting salt cores during casting. These cores are dissolved and removed with water introduced at very high pressure.

Fig. 7-18. Cooling channel piston with ring carrier for a diesel engine for passenger car use

Date added: 2022-12-29; views: 729;