Measures to Reduce Crankshaft Excursions

Without damping, the excursions of the crankshaft would become increasingly larger until the shaft breaks. In practice, however, damping always exists: Material damping, friction damping, and damping from the lubrication film. However, these are usually insufficient in today's highly stressed crank gears so that additional measures must be taken. To avoid hazardous rotational oscillation states, one can.

- Influence the exciter work by varying the firing sequence

- Shift the natural vibration frequency by changing the mass and spring rigidity

The feasibility and effectiveness of these measures is limited, however. An apparently simple measure is to increase the moment of inertia of the flywheel. This lowers the natural frequency, but at the same time the oscillating nodes are displaced toward the flywheel, and the shaft load is increased.

For these reasons, the only possibility is to reduce the rotational oscillations to a safe level. There are basically two options for this:

- Damping: Convert the vibration energy into heat. In the case of stationary forced vibrations and speed- proportional damping, there is an equilibrium between the moments of mass inertia, damping, return force, and excitation. The greater the damping moment, the smaller the vibration amplitude.

- Absorption: That is, "extinguishing" resonances by detuning the system, or, more precisely, shifting the natural frequencies into other speed ranges by counter-acting with a mass: By coupling an additional mass, the absorber, the system is given one more degree of freedom. The original natural frequency splits into two natural frequencies that lie closely above and below the original. If the system is excited in the original natural frequency, then it remains unexcited while the absorber vibrates. Such absorbers are effective only for a single frequency. A pendulum attuned to a specific vibration frequency and articulated to the oscillating system enters a reverse phase when this vibration arises and, hence, counteracts the exciting moment. The resonance speed is split and shifted upward or downward. Centrifugal force absorbers are speed dependent.

The effect of vibration dampers in passenger vehicle engines are based on both damping and absorbing. With regards to spring rigidity, damping behavior, and mass inertia, they are designed to continuously reduce rotational oscillation excursions of the system.

For passenger car engines, rubber vibration dampers are used: An annular damper mass (secondary part) connected to the primary-side L-shaped driving disk is elastically coupled via a vulcanized rubber layer. The vibration energy is converted by the material damping (hysteresis) of the rubber into heat. The resonance peak is divided into two resonances whose peaks are reduced by the damping.

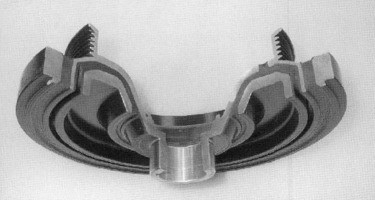

Depending on the design, the damper mass is affixed radially and/or axially to the primary part. Two-stage dampers are also used in which two damper masses are tuned to two different frequencies (Fig. 6-63). An example of this is with the two-mass rubber vibration damper for a five-cylinder diesel engine (2.5 L) in which both masses are harmonized to the torsion.

Fig. 6-63. Two mass rubber vibration damper (by Palsis) with vulcanized strips of rubber, V-belt strip on the primary side, primary side with shaft sealing flange made of St24W, secondary side made of GGG 40, primaryside moment of inertia Θ = 0.008 kg m2, secondary side 0.012 kg m2/220 Hz and 0.006 kg m2/360 Hz, rubber AEM (Vamac) (source: Palsis)

By reducing the rotational oscillation amplitude (Fig. 6-64), not only are the crankshaft and camshaft mechanically relieved, the play-induced noise of the engine and the excitation of the accessories to vibrate are reduced.

Fig. 6-64. Effect of a vibration damper

Passenger car engines increasingly require vibration dampers to deal with large engine dimensions (stroke volume) and greater specific work (effective average pressure) because of the stronger excitation. These are also used to lower natural frequencies as a result of greater crank gear masses. (The natural frequencies of passenger car crank gears range from 300 to 700 Hz.)

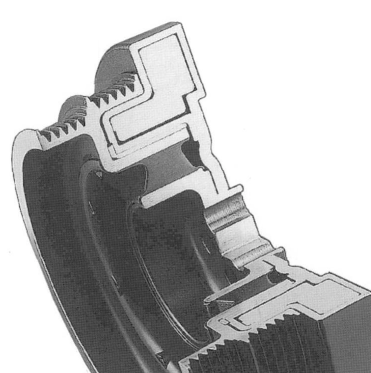

Recently, viscous dampers like the ones that have been used for larger engines have also been used (Fig. 6-65).

Fig. 6-65. Viscose vibration damper with a decoupled belt pulley (torsionally elastic rubber coupling) for inline six-cylinder diesel engines (Palsis)

Date added: 2022-12-29; views: 755;