Definition and Classification of Reciprocating Piston Engines

Piston machines are machines in which energy is transferred from a fluid (a gas or a liquid) to a moving displacer (e.g., a piston) or from the piston to the fluid. They are thus part of the category of fluid energy machines that, as driven machines, absorb mechanical energy in order to increase the energy of the conveyed fluid. In drive machines, on the other hand, mechanical energy is released in the form of useful work at the piston or at the crank mechanism.

The occurrence of a periodically changing working chamber as a result of the motion of the displacer (piston) is characteristic of the manner of operation of piston engines. One differentiates between reciprocating displacer engines and rotary displacer engines depending on the nature of the displacer's movement. In reciprocating piston engines, the displacer takes the form of a cylindrical piston that moves between two extreme positions, the "dead centers," in a cylinder. The term "piston" is also frequently applied to noncylindrical displacers. In rotary piston engines, a rotating displacer is normally responsible for varying the working chamber.

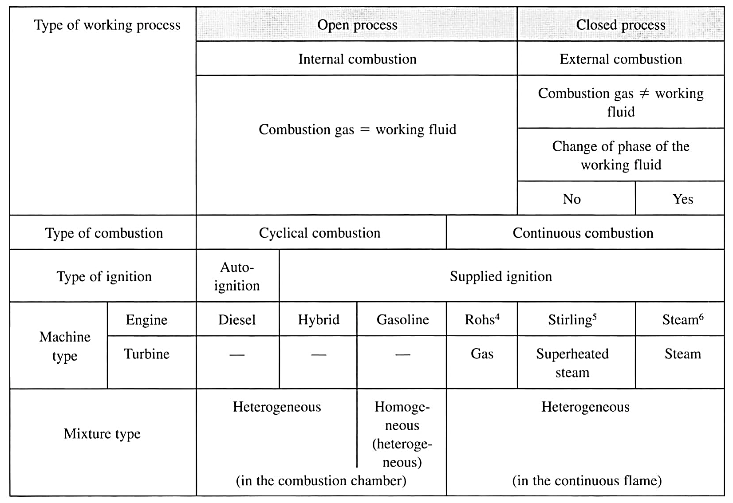

Combustion engines are machines in which chemical energy is converted to mechanical energy as a result of the combustion of an ignitable mixture of air and fuel. The best-known combustion engines are internal combustion engines and gas turbines. Figure 2-1 provides an overview.

Fig. 2-1. The classification of combustion engines

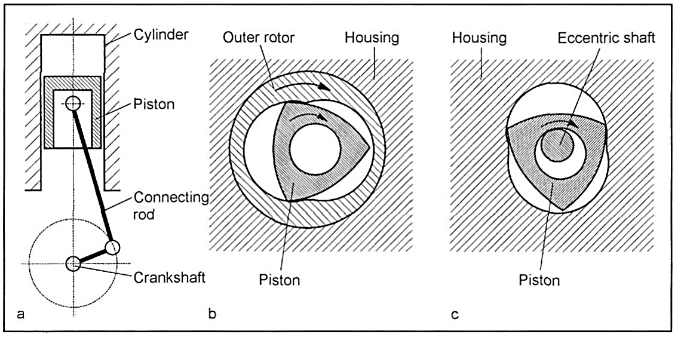

Internal combustion engines are piston engines. One differentiates between reciprocating piston engines (featuring oscillating piston movement) and rotary piston engines (featuring rotating piston movement) depending on the geometry of the gastight, changing working chamber and on the type of piston motion. Rotary piston engines are, for their part, subclassified again into rotary engines (featuring an internal and an external rotor with purely rotary motion about fixed axes) and planetary rotary engines (that feature an internal rotor, the axis of which describes a circular motion). Figure 2-2 shows the differing working principles. Only the Wankel engine, a planetary piston engine, has achieved any significance.

Fig. 2-2. The working principles of reciprocating piston engines, rotary engines, and planetary piston engines. (a) Trunk piston engine. (b) Rotary piston engine; power-yielding external rotor with epitrochoid internal contour and internal rotor as a sealing element. (c) Planetary piston engine (Wankel engine): Housing with epitrochoid internal contour and power yielding internal rotor that rotates eccentrically around a pinion and seals simultaneously.

It is also necessary, depending on the type of working process, to differentiate between combustion engines with internal combustion and those with external combustion. In engines featuring internal combustion, the working fluid (air) is simultaneously the source of the oxygen necessary for combustion. Combustion of the fuel fed produces waste gas, which must be replaced in a "gas exchange" cycle prior to every working cycle. Combustion is therefore cyclical, differentiation being made between gasoline, diesel, and hybrid engines, depending on the combustion process.

In the case of external combustion engines (such as the Stirling engine, for example), the heat produced outside the working chamber as a result of continuous combustion is transferred to the working fluid. This permits a closed-circuit working process and the use of any fuel. Only reciprocating piston engines featuring internal, cyclical combustion is examined from this point on.

Date added: 2022-12-29; views: 764;