Potentials for Classification. Combustion Processes. Configuration

The potentials for the classification of reciprocating engines are extremely diverse because of the complex interrelationships involved. Internal combustion reciprocating engines can be differentiated by their

- Combustion process

- Fuel

- Working cycle

- Mixture generation system

- Gas exchange control system

- Charging system

- Configuration

Further differentiating features may take the form of the

- Ignition system

- Cooling system

- Load-adjustment system

- Application

- Speed and output graduations

A number of differentiating features are currently only of historical significance, however.

Combustion Processes. Among the combustion processes, differentiation is made primarily between the Otto cycle and the diesel cycle. Hybrid engines exhibit characteristics of both the Otto cycle and the diesel cycle.

The gasoline engine is a combustion engine in which combustion of the compressed fuel + air mixture is initiated by means of synchronized extraneous ignition. In the diesel engine, on the other hand, the liquid fuel injected into the combustion chamber ignites on the air charge after this has previously been heated, by means of compression, to a temperature sufficiently high to initiate ignition.

In the case of hybrid engines, one differentiates between engines featuring charge stratification and multifuel engines.

Fuel. Gaseous, liquid, and solid fuels can be combusted in combustion engines:

- Gaseous fuels: Methane, propane, butane, natural gas (CNG), generator, blast furnace, biogas (sewage treatment and landfill gas), and hydrogen

- Liquid fuels: Light liquid fuels: Gasoline, kerosene, benzene, alcohols (methanol, ethanol), acetone, ether, liquefied gases (LNG, LPG)

Heavy liquid fuels: Petroleum, gas oil (diesel fuel), fatty-acid methyl esters (FAME), and, primarily in Europe, rape-seed methyl esters (RME), also referred to as "biodiesel," vegetable oils, heavy fuel oils, and marine fuel oil (MFO)

Hybrid fuels: Diesel + RME, diesel + water, and gasoline + alcohol

- Solid fuels: Pulverized coal

Working Cycles. In the field of working cycles, differentiation is made between four-stroke and two-stroke processes. Common to both is the compression of the charge (air, or a fuel vapor + air mixture) in the first step (stroke) by the reduction of the working chamber and ignition occurring shortly before the reversal of piston motion. Also, combustion associated with an increase in pressure up to the maximum cylinder pressure and the expansion of the working gas in the subsequent stroke, during which work is applied to the piston, is similar in both processes.

The four-stroke process requires two further strokes in order to remove the combustion gas from the working chamber by means of displacement and to fill the working chamber with a fresh charge by means of natural induction (normal aspiration).

In the two-stroke process, gas exchange occurs in the vicinity of bottom dead center as a result of expulsion of the combustion gases by the fresh charge with only a slight change in the working volume, with the result that the complete stroke is not exploited for compression and expansion. An additional scavenging blower is necessary for the scavenging process.

Mixture Generation. Combustion engines can be differentiated in terms of their type of mixture generation:

- External mixture generation: Formation of the fuel-air mixture in the inlet system

- Internal mixture generation: Formation of the mixture in the working chamber on the basis of the quality of mixture generation:

- Homogeneous mixture generation: Carburetor and intake manifold injection in the case of the gasoline engine, or gasoline direct injection during the induction stroke

- Nonhomogeneous mixture generation: Injection at extremely short intervals in the diesel engine and in gasoline engines with gasoline direct injection (GDI) and on the basis of the location of mixture generation:

- Direct injection into the working chamber in the case, for example, of DI diesel engines and GDI engines. Injection may be air-directed, jet-directed, orwall-directed.

- Indirect injection into a subsidiary chamber, such as antechamber, swirl-chamber, and air-chamber diesel engines.

- Intake manifold injection (in gasoline engines)

Gas Exchange Control. Valve, port, and slide-valve timing systems are used for control of the gas exchange.

In the case of valve timing mechanisms, one differentiates between overhead and side-actuated engines. The overhead-actuated engine has overhead valves; i.e., the closing movement of the valves occurs in the same direction as the movement of the piston toward top dead center (TDC). The side-actuated engine, on the other hand, has vertical valves, and closure of the valves occurs in the same direction as the movement of the piston toward bottom dead center (BDC).

Only the OHV arrangement, with overhead valves located in the cylinder head, is used in modern four-stroke engines. The camshaft may be located in the cylinder head or in the crankcase.

Two-stroke engines mainly employ port-based timing systems (slots, or "ports" in the cylinder sleeve, with the piston acting as a slide valve), and also bevel slide valves, disk valves, slide valves, and diaphragm timing systems in individual cases. In addition, a valve timing system (an exhaust valve in many cases) is also used in some recent motor-car and large marine engine developments.

Supercharging. In a normally aspirated engine, the fresh charge (air or mixture) is drawn into the cylinder by the working piston (natural aspiration).

Supercharging enlarges the quantity of the charge as a result of precompression; a supercharger conveys the fresh charge into the cylinder. The primary aims of supercharging are the enhancement of power and torque output and the reduction of fuel consumption and exhaust gas emissions.

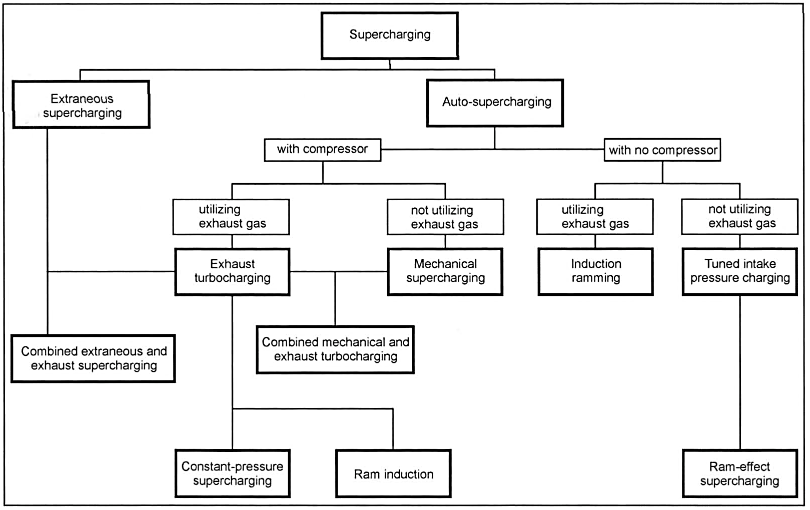

Figure 2-3 shows an overview of possible types of supercharging (after Ref. [11]). The most widely used and effective variant in practice is self- or auto-supercharging, using a compressor:

- Mechanical supercharging: The compressor is driven directly by the engine.

- Exhaust turbo-supercharging: A turbine (exhaust turbine) powered by the engine exhaust drives the compressor.

Fig. 2-3. Various supercharging methods, after Ref

Processes without a compressor, which exploit the gas-dynamic processes in the intake and exhaust systems to increase the charge, are also used.

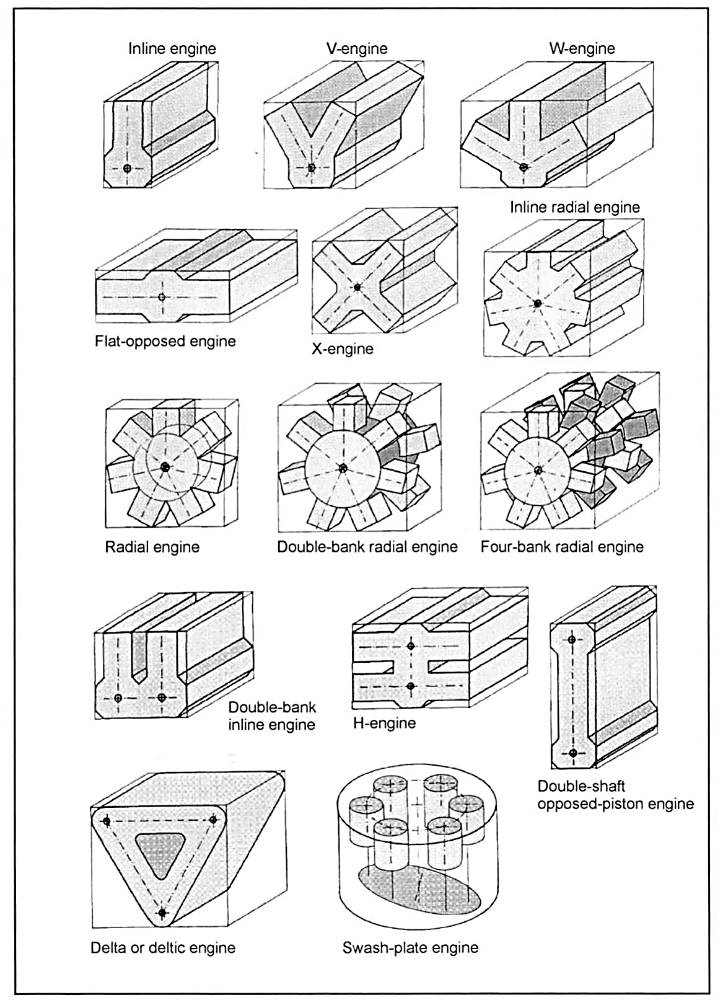

Configuration. Numerous variants of cylinder arrangement have been suggested in the more than 120-year history of the internal combustion engine. Only a few standard configurations have stood the test of time.

Starting from the single-cylinder engine, the number of cylinders selected can range up to as high as 12 in the case of vehicle engines. Aircraft engines with up to 28, or even as many as 48 cylinders, and high-performance engines with up to 56 cylinders have also been constructed.

There are numerous possible combinations for the cylinder arrangement, some of which are identified in a self-explanatory manner by letters. Figure 2-4 shows a selection of possible cylinder arrangements and configurations.

Fig. 2-4. Cylinder arrangements in reciprocating piston engines

The following are presently of significance:

- The inline engine (one bank of cylinders and one crankshaft).

- The V-engine (two banks of cylinders and one crankshaft): Two connecting rods are coupled to each crank pin. Common V-angles are 45°, 60°, 90°, and 180°. The VR engine has a V-angle of 15°, the crankshaft having a separate crank pin for each connecting rod.

- The W-engine (three banks of cylinders and one crankshaft): Three connecting rods are connected in each case to one crank pin. A V-engine consisting of two VR banks is referred to as a V-VR engine, or also as a W-engine.

- The boxer (flat-opposed) engine: Unlike the 180° V-engine, each connecting rod is connected to a separate crank pin.

The crank mechanism has proven its value in engine design. Trunk piston engines and crosshead engines may be differentiated as variants. Slider crank mechanisms and cam engines are also described in the relevant literature, as are crankshaftless engines (curved-plate, curved-track, and swash-plate engines).

Single- and double-acting engines can be differentiated according to their manner of action, depending on whether the combustion gases act on only one side or on both sides of the piston. The double-piston engine has two pistons to each combustion chamber, the pistons being arranged either opposing (opposed-piston engine) or concurrent (U-piston engine)

Vertical, horizontal, and overhead engines are differentiated on the basis of the location of the cylinder axis, and overhead-actuated and side-actuated engines by the location of the timing mechanism.

Date added: 2022-12-29; views: 654;