Heating. Remote heating systems

Heating systems are distinguished by the type of energy source and type of heating surface.

Oil firing: nowadays, light. Advantages: low fuel costs (relative to gas, approx. 10-25%); not dependent on public supply networks fuel oil is the most widespread source of heating energy; easy to regulate. Disadvantages: high costs of storage and tank facilities; in rented housing, space required for oil storage reduces rent revenue; where water protection measures apply or there is a danger of flooding, this form of heating is only possible if strict regulations are observed; fuel paid for prior to use; high environmental cost.

Gas firing: natural gas is increasingly being used for heating purposes. Advantages: no storage costs; minimal maintenance costs; payment made after usage; can be used in areas where water protection regulations apply; easy to regulate; high annual efficiency; may be used for individual flats or rooms; minimal environmental effects. Disadvantages: dependent on supply networks; higher energy costs; concern about gas explosions; when converting from oil to gas; chimney modifications are required.

Solid fuels such as coal (anthracite), lignite or wood, are rarely used to heat buildings. District heating stations are the exception, since this type of heating is only economical above a certain level of power output. Also, depending on the type of fuel used, large quantities of environmentally damaging substances are emitted, so that stringent requirements are laid down for the use of these fuels (protection of the environment). Advantages: not dependent on energy imports; low fuel costs. Disadvantages: high operating costs; large storage space necessary; high emission of environmentally unfriendly substances; poor controllability.

Regenerative forms of energy include solar radiation, wind power, water power, biomass (plants) and refuse (biogas). Since amortisation of the installation costs is not achieved within the lifetime of the plant required, the demand for this type of energy is correspondingly low.

Remote heating systems are indirect forms of energy supply, as opposed to the primary forms of energy discussed above. Heat is generated in district heating stations or power stations by a combined heat/power system. Advantages: boiler room and chimney not required; no storage costs; energy is paid for after consumption; can be used where water protection regulations apply; environmentally friendly association of power/energy coupling. Disadvantages: high energy costs; dependency on supply network; if the heating source is changed, a chimney must be fitted.

Electrical heating: Apart from night storage heating, the continuous heating of rooms by electrical current is only possible in special cases, due to the high costs of electricity. Electrical heating of rooms in temporary use may be advantageous, e.g. garages, gate keepers' lodges and churches. Main advantages: short heating-up period; clean operation; no fuel storage; constant availability; low initial costs.

Night storage heating is used for electrical floor heating, electrical storage heaters or for electrically heated boilers. Off-peak electricity is used to run the heaters. For electrical floor heating, the floor screed is heated overnight to provide heat during the day to the room air. Correspondingly, for electrical storage heaters and electrically heated boilers, the energy storage elements are heated during the off-peak period. However, by contrast to the floor heating system, the latter two devices can be regulated. Advantages: neither a boiler room nor chimney is required; no gases are generated; minimal space requirement; low servicing costs; no need to store fuel.

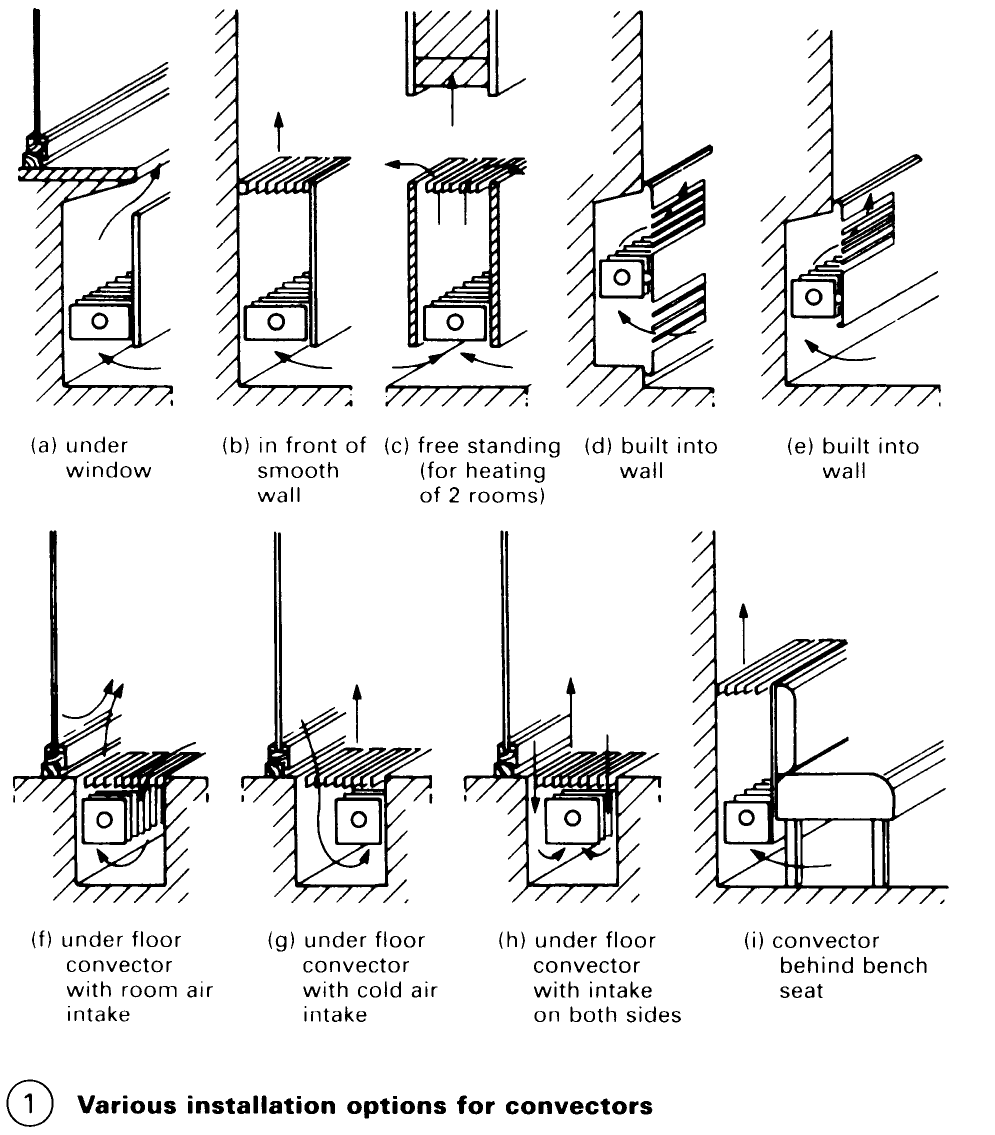

Convectors: Heat is not transferred by radiation, but by direct transmission to the air molecules. For this reason, convectors can be covered or built in, without reducing the heat output. Disadvantages: strong movement of air and the dust swirling effect; performance of convector depends on the height of the duct above the heated body; crosssections of air flowing into and away from the convector must be of sufficient size. ф For under-floor convectors – (1)f – (1)h, the same prerequisites apply as for above-floor convectors. The disposition of the under-floor convectors depends on the proportion of heating requirement for the windows as a fraction of the total heating requirement of the room. Arrangement – (1) f should be adopted if this proportion is greater than 70%; arrangement – (1) h for 20-70%; if the proportion is less than 20%, then arrangement – (1) g is favoured.

Convectors without fans are not suitable for low-temperature heating, since their output depends on the throughput of air and, hence, on the temperature difference between the heated body and the room. The performance of convectors with too low a duct height (e.g. floor convectors) can be increased by the incorporation of a blower. Blower convectors are of limited use in living-room areas, due to the build-up of noise. Heaters can be covered in various ways. Losses in efficiency can be considerable, and attention should be paid to adequate cleaning. For metal cladding, the radiative heat contribution is almost entirely given to the room air.

For material coverings with a lower thermal conductivity, the radiative heat is damped considerably. A representation is shown of the movement of air within a heated room. The air is heated by the heater, flows to the window and then to the ceiling and is cooled on the external and internal walls. The cooled air flows over the floor and back to the heater. A different situation arises if the heater is on a wall which is away from the window: air cools on the window, then flows cold over the floor to the heater, where it is heated up.

Date added: 2023-01-05; views: 636;