Refrigeration, Mechanical. Vapor-compression Refrigerator

Over 170 years elapsed between William Cullen’s experiments on refrigeration at the University of Glasgow and the mass production of mechanical- compression refrigerators for the consumer market in the 1920s.

Beginning with Cullen in 1748, scientists and inventors across the Western world manipulated the basic properties of the elements to produce ice and cold air. The most prominent methods of refrigeration included air-cycle compression, vapor compression (or mechanical compression), thermoelectric, and absorption. While no single method proved superior in all circumstances, mechanical-compression refrigeration emerged by the 1940s as the dominant method for both domestic and industrial refrigeration.

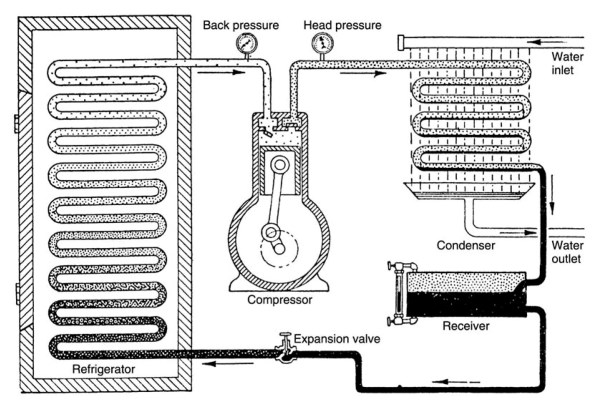

Inventors throughout the Western world contributed to the development of mechanical-compression refrigeration throughout the nineteenth century. Oliver Evans, the American inventor of the automated flour mill, laid the foundation for the continuous-cycle vapor-compression refrigerator (see Figure 26) when he conceived a method in 1805 for recycling vaporized refrigerant. After removing heat from the surrounding environment, vaporized refrigerant would move through a compressor, and then a condenser, where it would revert back into a liquid form and begin the process again.

Figure 26. Vapor-compression refrigerator

Although Evans failed to transform his idea into a practical device, Jacob Perkins, an American- born resident of London who befriended Evans during a stay in Philadelphia, built on Evans’ ideas to construct a cyclic vapor-compression machine in 1834. The Perkins machine, which used ether as a refrigerant, was the first full-scale machine to contain a compressor, a condenser, an expansion valve, and an evaporator—the basic parts of the modern mechanical-compression refrigeration system. Perkins, however, never developed his machine for commercial use.

Dr. John Gorrie, the director of the U.S. Marine Hospital in Apalachicola, Florida, received a patent in 1851 for the first refrigeration system operated for practical use. Gorrie, however, installed his machine only at his own hospital, and it was an air-cycle compression machine rather than a vapor-compression machine.

Whereas the refrigerant in a vapor-compression machine alternates between a gaseous and a liquid state, the refrigerant in an air-cycle compression machine— air—remains gaseous throughout the compression and expansion cycles. Alexander Twining, a college professor and practicing civil engineer, received a patent in 1853 and built the first commercially viable continuous-cycle vapor-compression refrigeration machine based on Jacob Perkins’ original design.

Several inventors subsequently developed large-scale compression machines for industrial settings that varied from Twining’s machine only in component design and choice of refrigerant. Many of the early machines used ether, a highly volatile and toxic substance, as a refrigerant. In the 1870s, David Boyle in the U.S and Carl von Linde in Germany introduced ammonia, a less toxic refrigerant that changed states more readily than ether. However, other more toxic refrigerants remained in use alongside ammonia. Reciprocating compressors were first developed in 1880 for industrial applications, such as ice making, brewing, and meat packing.

Demand for domestic refrigeration emerged by the 1880s, as indicated by the widespread use of iceboxes in households. Rudimentary mechanical refrigeration units for the home first appeared in 1910, and the Kelvinator Corporation began quantity production of the first domestic refrigerator unit with automatic controls in 1918. These early machines, however, were unreliable, expensive, plagued with technical problems, and even dangerous.

Most systems used sulfur dioxide or methyl chloride as refrigerants, both of which are highly toxic. Even less-toxic ammonia could prove lethal if it leaked, and leakage was a constant problem with the early machines. They also required regular servicing due to chronic problems with thermostats, motors, and compressors. The separation of the refrigerating machinery from the refrigeration compartment exacerbated these problems by forcing the compressor to work harder.

The redesign of the refrigerating unit and the development of a new class of refrigerants helped to increase the reliability and safety of mechanical- compression refrigerators. General Electric developed the first hermetically sealed motor-compressor for domestic refrigeration in the mid- 1920s. The GE Monitor Top, which was based on a 1905 design by Audiffren in France, contained all its mechanical parts in a single unit, ingeniously placed on top of the refrigerator box.

The machine was air cooled and made of steel rather than wood, which was commonly used for most machines at the time. Other manufacturers soon replicated GE’s design. By 1940, almost all domestic refrigerators were self-contained units and made of steel with no external parts.

The discovery of chlorofluorocarbon (CFC) refrigerants by Thomas Midgely and a team of researchers at General Motors in the late 1920s eliminated the immediate health and safety hazards of refrigeration. The company announced its discovery in 1930. Soon thereafter, the Kinetic Chemical Company, a joint venture of GM and DuPont, began manufacturing the CFC refrigerant known commercially as Freon.

Although General Motors initially intended to restrict use of Freon to machines produced by its Frigidaire Division, the benefits and the potential profits from widely distributing the nontoxic and nonflammable refrigerant were too great to resist. Within a few years Freon became the refrigerant of choice for mechanical-compression refrigerators.

Other important landmarks in the history of refrigeration include the development of the humidity drawer for fruits and vegetable in 1930, General Electric’s 1939 introduction of the dual temperature refrigerator, which had separate compartments for chilled and frozen foods, and Frigidaire’s replacement of reciprocating compressors with quieter and smaller rotary compressors in 1933. Automatic defrosting was introduced in the early 1950s.

Whereas immediate health and safety concerns stimulated the development of chlorofluorocarbon refrigerants, long-term environmental concerns led to the abandonment of CFCs. In 1974 two chemists at the University of California at Irvine, F. Sherwood Roland and Mario Molina, discovered that chlorine atoms catalytically break down ozone when exposed to high-frequency ultraviolet light. Roland and Moline concluded that CFCs were stable enough to pass through the troposphere but would decompose and release chlorine in the stratosphere, where they would deplete the earth’s ozone shield.

Not until the British Antarctic Survey discovered a hole in the ozone layer in 1985, however, did concern over CFCs become widespread. In keeping with their commitments under the 1987 United Nation’s Montreal Protocol, industrialized nations abandoned the use of CFCs by 1996. The search for refrigerants to replace CFCs yielded new chemical compounds, such as hydroflourocarbons (HFCs), which were less damaging to the ozone layer. However, no single refrigerant emerged as a global standard. Research on refrigerants and refrigeration methods at the end of the twentieth century was as vibrant as it was at anytime during the century.

Date added: 2023-10-27; views: 792;