Refrigeration, Absorption. Absorption Refrigeration Machine

William Cullen’s seminal experiments on the evaporation of liquids in the 1750s served as a precursor to the development of absorption refrigeration. Cullen, who accepted a chair in chemistry at the University of Edinburgh in 1756, demonstrated the possibility of refrigeration when he produced a small amount of ice through vaporization by reducing the pressure under a bell jar.

One of Cullen’s students, Joseph Black, made an important contribution to both physics and refrigeration engineering with his articulation in 1761 of the theory of latent heat, which accounts for the release and absorption of heat as a substance changes state. Another of Cullen’s students at Edinburgh, Edward Nairne, improved upon the pioneer’s laboratory experiments by placing a cup of sulfuric acid along with a cup of water under a partially evacuated bell jar.

The sulfuric acid absorbed the vaporized water and thereby hastened the evaporation process. Nairne’s successor at Edinburgh, John Leslie, and later a British brewer named John Vallance made further improvements to Nairne’s sulfuric acid-water absorption device in the early part of the eighteenth century, but neither developed their devices beyond the experimental stage.

Edmund Carre, a French inventor, developed a sulfuric acid absorption refrigeration device in the 1850s. Although it was installed in a number of bars and restaurants in France, the device malfunctioned and underwent disabling corrosion. Edmund’s brother, Ferdinand Philippe Eduard Carre;, concluded that the problem was not the device itself, but the choice of refrigerant. By replacing the sulfuric acid and water mixture with an ammonia and water mixture, Ferdinand Carre; developed the first successful absorption refrigeration system.

The initial Carre; device had just two components. One component combined the functions of a generator and an absorber; the other combined the functions of a condenser and an evaporator. Because of the dual functions of each component, the machine operated intermittently rather than continuously. Soon thereafter, however, Carre; developed a continuous machine.

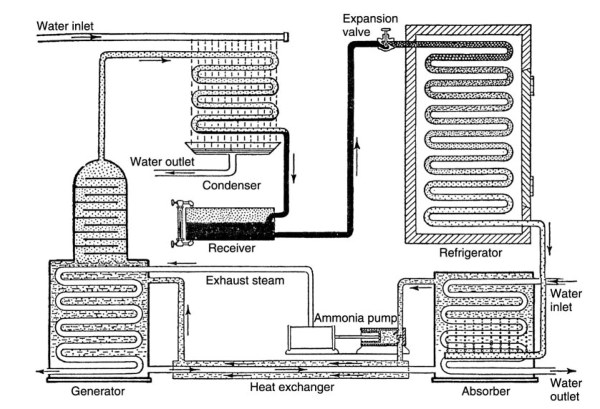

The Carre; absorption unit had all of the components of a modern day absorption machine, including: an evaporator, an absorber, a generator, an expansion valve, and a pump. In ammonia- water absorption systems, the ammonia refrigerant flows at low pressure through the evaporator where it absorbs heat from the refrigerator cabinet. It then moves to the absorber where it mixes with water. The water and ammonia mixture is then pumped into the generator, and the heat of the generator separates the mixture into water and high-pressure ammonia gas.

The water returns to the absorber, and the ammonia gas then flows into the condenser, where cool water passing over the outside of the coils removes heat from the ammonia and allows it to return to a liquid form. From there, the ammonia gas moves through an expansion valve and is ready to flow back into the evaporator where, once again, it absorbs heat from the refrigerator cabinet (see Figure 25).

Figure 25. Absorption refrigeration machine

The absorption machine gained quickly in popularity. It was adopted and produced in Germany, Great Britain, and the U.S. Carre; refrigeration units were shipped through Union blockades during the U.S. Civil War to a military hospital in Augusta, Georgia, and King Ranch near Brownsville, Texas. Manufacturers readily improved upon the Carre; design.

The use of wood chips to heat the generator was the most glaring problem with the machine. To gain greater control over the heating process, manufacturers of industrial machines replaced the wood-burning system with steam coils. Manufacturers developed more efficient rectifiers and new types of absorbers throughout the late nineteenth and early twentieth centuries.

The refrigeration units were developed almost exclusively for large-scale commercial establishments, such as ice-making plants and breweries. The production process, therefore, resembled a construction operation. Without the possibility of stable designs, refrigeration companies depended on specialty manufacture, craft skill, and on-site engineering improvements to build their systems.

A number of characteristics distinguish absorption refrigerators from mechanical-compression systems. Both force the evaporation and condensation of a refrigerant to transfer heat across physical boundaries, but the absorption system uses heat to generate the pressure necessary to enable the evaporation process, while the mechanical-compression system relies on an electric-powered compressor.

Rather than mechanical processes and electrical energy, the absorption system depends on heat and physiochemical processes for its operations. The absorption system, furthermore, has more components than its competitor, has no moving parts, and has a refrigerant consisting of two substances, not one.

Absorption refrigeration remained competitive with compression systems up to World War I in the U.S. During the interwar years, however, absorption refrigeration for both industrial and domestic settings plummeted in popularity. The higher initial cost of absorption machines and the inability of manufacturers to match the innovations of producers of compression systems are only part of the story. Household absorption refrigerators depended on gas heat, while the compression systems depended on electrical power.

The emerging giants of the electrical industry in the U.S.—General Electric, Westinghouse, and the Frigidare Division of General Motors—and their well-financed partners in the electrical utility industry were able to muster far greater financial and technical resources than producers of absorption refrigeration systems.

The single major producer of absorption refrigerators, Servel, was at too great a financial disadvantage to compete with the electrical industry in research and development, and marketing. Absorption refrigeration, however, did not vanish from the marketplace. Despite its early eclipse, it occupied an important niche in the global refrigeration market throughout the twentieth century.

Date added: 2023-10-27; views: 707;