Systems with Stepped Variation of the Valve Stroke or Opening Time

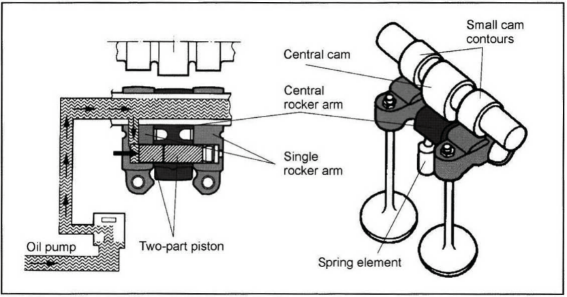

Honda used variable valve actuation for the first time in the mass production of spark-ignition engines with its VTEC system that influences the valve stroke or valve opening time. The principle is based on a rocker arm solution in which, by moving small, hydraulically actuated pistons inside the rocker arm, different coupling states can be achieved to allow switching between different cam contours. Figure 10-77 shows an outline of the system used in a four-valve engine with dual camshafts.

The right part of the figure shows an isometric representation of the valve and camshaft arrangement. For each cylinder, the camshaft has a central cam with a large valve stroke and opening time geometry. To the side is a cam profile with smaller cam contours. Inside the rocker arm module, a two-part piston is shifted by oil pressure parallel to the axis of the camshaft. This is done depending on the engine mapping as a function of the engine speed, the induction pipe pressure, the vehicle speed, or the coolant temperature. The oil is supplied for switching the cam contour through openings and channels in the bearing shaft on which the rocker arm module pivots. When operating at low speeds, the smaller cam contours act on the gliding surface of the rocker arm.

Fig. 10-77. Honda VTEC system

The rocker arms are separated by precisely harmonizing the geometry of the two-part adjusting piston with the rocker arm width. A relative stroke is created between the central rocker arm and the individual rocker arms on the side. The central rocker arm is supported on a spring element. The space for this must be created in the cylinder head. In cylinder head designs with more than four valves, this is a particular challenge to the developer. When coupled as shown in Fig. 10-77, the central cam acts on the rocker arm module, and all components are moved simultaneously without a relative stroke. The two-part adjusting piston is reset with a small spring. The adjusting oil pressure is established by the engine oil circuit without an additional oil pump. The VTEC system is located on the intake and exhaust valve side.

For this and similar solutions, Honda developed numerous patent applications. By the number of different inventors alone of the patent applications, we can guess at the enormous amount of development. Four-valve solutions with one or two camshafts have been created for production engines. Both rocker rollers and rocker arms with sliding surfaces are used. Up to three differently acting cam contours have been realized in this context.

Mitsubishi has also developed a similar series system for four- and six-cylinder engines based on the same functional principle. In this solution, three cam contours are used, and one cam contour consists of a base circle to stop the valve. With both engines, two and three cylinders are stopped using this valve actuation system. To achieve this, Mitsubishi requires a small oil pump in the cylinder head.

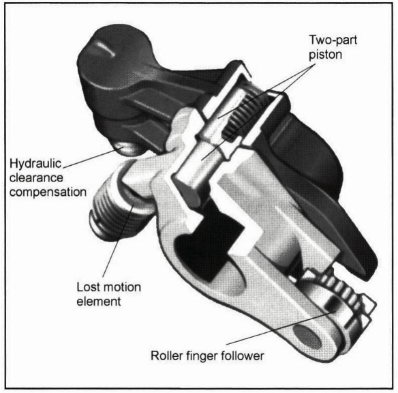

DaimlerChrysler uses variable valve actuation to stop the cylinders in its stock V8 and V12 engines. The solution is based on a valve rocker module that is used with a central camshaft in a three-valve approach. Figure 10-78 shows the valve rocker module of this system without a camshaft. The functional principle is the same as the above-described Honda solution. Inside the rocker roller module, a two-part adjusting piston is moved electrohydraulically against a spring force. Depending on the coupling state, different cam contours are selected between valve strokes, except that one valve stroke is a zero stroke, and this stops the valves to shut off the cylinders.

Fig. 10-78. Rocker roller module to stop the valves by DaimlerChrysler

The primary goal of the system used in this instance is to reduce fuel consumption during partial load operation by stopping the cylinders. This is particularly effective with high-displacement engines with many cylinders. There is little effect on the smooth running of these engines. These measures can reduce consumption by approximately 15% in contrast to conventional engines.

Similar to Mitsubishi and Honda, Toyota has also pursued solutions for mass production involving switching the valve contour on the intake and exhaust valve side. In this case as well, an adjusting piston in a rocker arm module is electrohydraulically pushed against a spring force (Fig. 10-79).

Fig. 10-79. Toyota valve actuation VVTL-i for different valve strokes

The interesting fact about this solution is that a rocker arm module is used in which a roller is the contact surface that faces the cam at low speeds, and a sliding surface is used at high speeds. At high speeds, the rocker arm module is pivoted by the sliding contact, and a stop below the lost-motion element provides coupling.

The stop is held by oil pressure and is moved by spring force at low speeds toward the bearing center of the rocker arm module. At high speeds, the sliding surface lowers with the lost-motion element into the rocker arm module. The spring force of the lost-motion element can be minimal since the moved mass of the element is also low. For this solution, Toyota also uses a continuously variable camshaft adjuster on the intake valve side. This combination allows the valve lifting curve to be widely varied in contrast to engines with fixed control times.

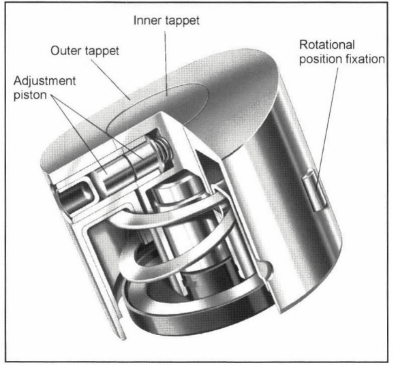

Porsche has traditionally used bucket tappet solutions for four-valve engines. In 2000, Porsche presented a turbo engine for the first time with variable valve actuation using different valve strokes with a switching bucket tappet.

In addition, a camshaft control device was placed on the intake valve side to offer two control time positions. As with Toyota, a combination of two independently functioning systems of variable valve actuation is used. The switching bucket tappet can execute two valve strokes and consists of an inner and an outer tappet (Fig. 10-80).

Fig. 10-80. Switching bucket tappet by Porsche

Its rotational position is oriented by a special guide in the cylinder head. The surface can be ball-shaped for correspondingly strong maximum strokes. Inside the tappet are small hydraulically actuated pistons that activate the inner or outer tappet for valve actuation depending on the position. In this case as well, the term “mechanically variable valve actuation” is appropriate since only the adjusting piston is electrohydraulically controlled, and the valves are actuated by the mechanical positive engagement of the components.

Usually a new generation of cylinder heads is used with this type of valve actuation. The geometry of the cam contours is conventional; i.e., they are smooth and can be manufactured by normal cam production systems. Corresponding to the categorization in Section 10.4, these solutions represent systems with a variable transmission element between the cam and valve. The functional principle is mechanical since only mechanical actuators and contact elements are used in the flow of force toward valve actuation. The adjusting piston is controlled hydraulically via an electrically actuated directional control valve. It is anticipated that these or similar systems will become more widespread in production engines.

Date added: 2024-11-26; views: 358;