Infinitely Variable Valve Actuation

In the following, we briefly discuss a few systems that enable an infinitely variable valve lifting curve. These are systems that use camless controls as well as those with a mechanical functional principle that use a camshaft.

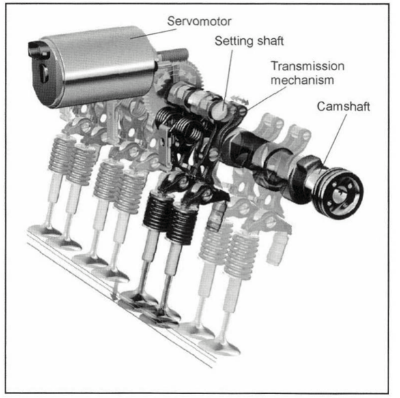

Mechanical Systems. With its Valvetronic system, BMW has created a continuously variable valve actuation system on the intake valve side. The load of the engine can be controlled solely by variable valve lifting. The system uses a special force transmission mechanism between the cam and valve and, corresponding to the categorization in Section 10.4, is classified as a mechanical variable valve actuation system. In Fig. 10-81 we see the Valvetronic system with the intake camshaft and intake valve module. In the flow of force between the camshaft and valve, there is a transmission mechanism that swings the roller rocker arm to actuate the valves.

Fig. 10-81. "Valvetronic" system by BMW as a module with the valve gear components

A setting shaft designed as an eccentric shaft and driven by an electrical control motor changes the lever geometry of the transmission mechanism. Valve strokes between 0.3 and 9.7 mm can be set. The entire adjustment processing can take place within 0.3 s. The conventional throttle valve can be dispensed with. The friction loss of the valve gear can be reduced during operation by the variable valve strokes in comparison to conventional valve gears since the valve springs are compressed less with smaller valve strokes.

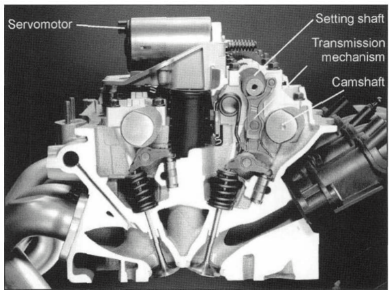

Figure 10-82 shows an installed variable valve actuation system in a cross section of a cylinder head. The exhaust valve side remains conventionally actuated with a rocker arm. The required space for valve actuation is kept within limits. Space in the vehicle is required only for the control motor. The eccentric shaft, the transmission mechanism, the camshaft, and the control motor are premounted in a separate cast holder and attached as a module to the cylinder head.

Fig. 10-82. Arrangement of the "Valvetronic" system in a cylinder head

Similar systems have also been developed. They have not yet been found in stock engines, however. BMW has also used continuously variable camshaft adjusters on both camshafts in addition to the variable stroke. The variation of the control times that can be attained is substantial. This combination was used first in a four-cylinder engine in compact passenger cars. In contrast to the predecessor model, savings in consumption of approximately 15% have been attained.

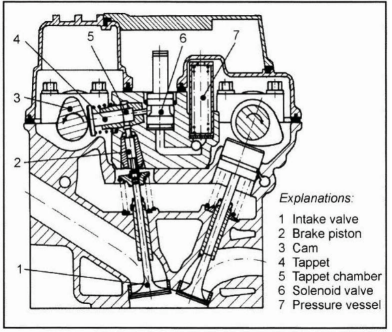

Hydraulically Actuated Systems. In the 1980s, there was a whole series of research efforts dealing with hydraulically variable valve actuation. The developmental goal was a freely settable valve actuation via the medium of oil. An example of a design to change the control times based on a hydraulic functional principle is the system by Fiat shown in Fig. 10-83. Developments toward similar solutions were made at many companies.

Fig. 10-83. Hydraulically variable valve actuation by Fiat

The intake valve is actuated via the camshaft and a hydraulic transmission mechanism. With the movement of the tappet in the tappet chamber, pressure builds that moves the piston above the valve and, hence, moves the valve. The oil pressure in the tappet chamber can be interrupted by a solenoid valve. This limits the valve stroke, and the engine load can be controlled without a throttle valve. Oil can be conveyed to the tappet chamber via a small pressure tank. The solenoid valve must be designed to switch extremely quickly. A problem with this type of valve actuation is the operating behavior at low temperatures and the related strongly differing oil viscosities. A reproducible valve lifting curve is also difficult to obtain.

At present, there are few activities in the area of variable valve actuation. The only development of which we are aware is by Fiat. Whether these systems have a chance at being used in stock engines is difficult to determine.

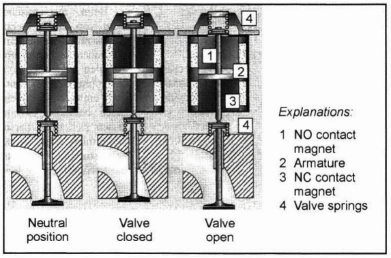

Electromechanical Systems. Camless systems have the greatest potential for varying the valve lifting curve. They use valve actuators that can individually set any control time of any valve. Based on this idea, there have been investigations of valve actuation with an electromechanical functional principle for about 20 years. An armature between two coils alternately supplied with power is connected to the charge cycle valve via the armature guide. In addition, springs are used that actuate the armature and the valve. The armature is excited to vibrate when the bottom or top coil is supplied with power.

The valve stroke can be set from 0 mm to a maximum stroke, and the load of the engine can be controlled by widely varying the valve lifting. Figure 10-84 shows the basic construction of this type of control. To open the valves, the opener magnet is excited with current, and the closer magnet is excited to close it. When the coils are not excited with current, the armature and, hence, the valve remain in midposition between the coils. This position is held by the spring. In case of a system failure or engine stoppage, there is a corresponding clearance in the piston.

Fig. 10-84. Functional representation of an electromechanically variable valve gear

The future will show the degree to which this type of variable valve actuation will replace the purely mechanical valve actuation in stock engines. The additional potential for thermodynamic improvement in comparison to systems such as the Valvetronic system by BMW mentioned in Section 10.4.3.1 is limited.

Date added: 2024-11-26; views: 350;