Distributor Injection Pump

In addition to the inline fuel injection pump, the distributor injection pump is the second most familiar compact pump design. It consists of a low-pressure supply pump, a high- pressure supply pump, a timing device unit, a speed and fuel governor, and various mechanical and electrical components. The high-pressure pump can either be designed either as an axial piston pump or as a radial piston pump.

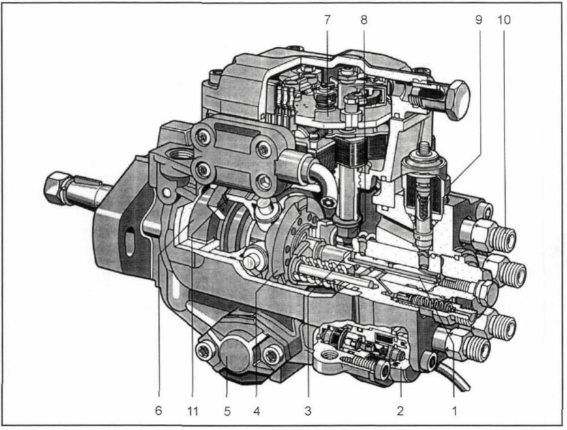

Figure 12-32 shows an axial piston pump with edge- controlled fuel metering and an electromagnetic actuator mechanism. In contrast to the inline pump, this pump is distinguished in that only one pump element is required for all engine cylinders. This is possible because the frequency of the stroke of the pump plungers corresponds to the ignition frequency of the internal combustion engine and not that of an individual engine cylinder. At the same time, the pump plunger rotates at the camshaft speed.

Fig. 12-32. Axial piston distributor injection pump, edge controlled with electromagnetic actuator mechanism designed by Bosch. 1, Distributor plunger; 2, Solenoid valve for timing; 3, Control collar; 4, Timing device; 5, Cam plate; 6, Supply pump; 7, Electrical fuel quantity positioner with feedback sensor; 8, Actuator mechanisms; 9, Electrical shutoff device; 10, Pressure valve holder; 11, Roller holder

The fuel is fed to the engine cylinders by the stroke of the plunger. The rotation distributes the fuel to the engine cylinders corresponding to the firing sequence. This dual function of the plunger allows the distributor injection pump to be used for engines with up to six cylinders. The applications for this pump are, in particular, for highspeed diesel engines for passenger cars and light commercial vehicles. In individual cases, they can also be used for medium-duty class engines. The nozzle-side injection pressure reaches values of 1200 to 1300 bar.

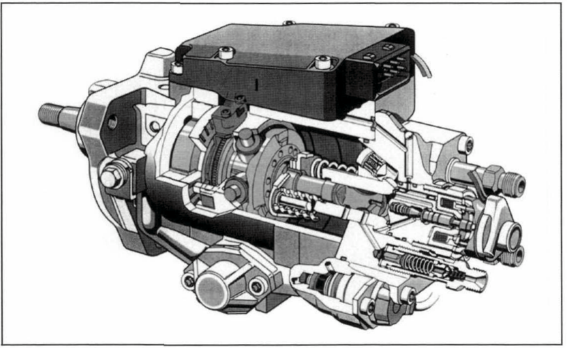

A particular advantage of the distributor injection pump is the integration of a solenoid-valve-controlled timing device. This makes it particularly suitable for engines with a large speed range. Instead of electromagnetic actuator mechanisms, an inertia-supported actuator assumed mechanical control of the timing of the control sleeve and, hence, the fuel metering mechanisms in the older conventional design. A further development of the axial piston distributor pump is shown in Fig. 12-33.

Fig. 12-33. Axial piston distributor pump, cam time controlled with solenoid valve; designed by Bosch

This is a cam-time-controlled pump that has a solenoid valve in the high-pressure area that can control both the charging of the pump element and the start and end of delivery (hence, the delivery quantity). Because of the slight amount of dead space in the high-pressure area of the pump, pressures of approximately 1500 bar can be attained with this variation. An electronic control unit is on the pump body that assumes the pump control functions, in particular, the activation of the fuel solenoid valve and the solenoid valve for timing the start of delivery. The information for this is provided from the pump internal incremental pump angle time signal (increment angle time signal).

This is generated by the speed or angle-of-rotation sensor on the trigger wheel of the drive shaft. The position of the sensor is changed together with the adjustment of the roller ring necessary for timing the start of delivery. With the cam plate speed (camshaft speed) and the assignment of the delivery stroke to the TDC signal of the crankshaft speed sensor, the start of delivery can be precisely timed without a needle motion sensor in the nozzle-holder assembly having to provide the information at the beginning of injection. At the same time, the increment angle time signals can set the exact control time of the fuel solenoid valve and hence the fuel metering. The pump electronic control unit (ECU) is connected to the second ECU, the engine control unit, or it can contain its functions so that only one more electronic control unit is necessary. The drive and the timing devices are similar to the edge- controlled axial piston distributor injection pump.

In distributor injection pumps with a radial piston high-pressure pump, the pressure generation function and the distribution function are separate. As the name indicates, the pressure generation piston is in a radial position. The fuel metering can be controlled by either the cam pitch or the cam time via solenoid valves—similar to the solenoid-valve-controlled axial piston distributor pump.

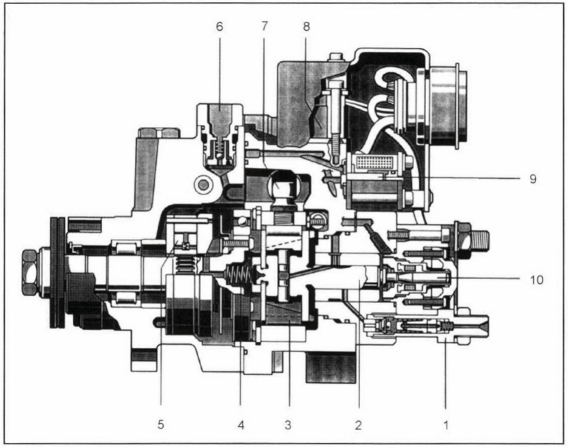

Figure 12-34 shows a cam-pitch-controlled radial piston distributor pump. With this type of pump, the delivery stroke (that corresponds to the respective overall stroke) is changed by axially shifting the ignition distributor shaft and by conical surfaces. The axial position of the ignition distributor shaft is detected by an inductive travel sensor and represents a measure of the delivery stroke or the delivery quantity. This pump is also primarily used for passenger cars similar to the axial piston distributor pump.

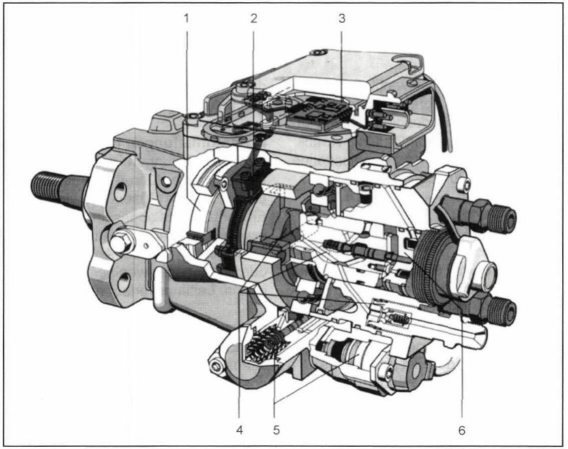

To attain the maximum injection pressure, a radial piston pump was developed with a higher supply rate and solenoid valve control (Fig. 12-35).

Fig. 12-34. Radial piston distributor injection pump, stroke controlled and electronically controlled. 1, Delivery valve holder; 2, Ignition distributor shaft; 3, Slippers; 4, Return spring; 5, Supply pump; 6, Pressure holding valve; 7, Timing device; 8, Solenoid valves (timing device, return); 9, Solenoid valves (shut-off, charging); 10, Sensor for axial rotor position

Fig. 12-35. Radial piston pump, cam time controlled with solenoid valve. 1, Vane-type supply pump with pressure control valve; 2, Angle-of-rotation sensor; 3, Pump ECU; 4, Radial piston high-pressure pump with ignition distributor shaft and outlet valve (pressure valve); 5, Timing device, and timing device solenoid valve (pulse valve); 6, High-pressure solenoid valve

With this pump, injection pressures of 1800-1900 bar can be attained. A cam ring bears inner radial cams whose stroke is transferred via rollers and slippers to the radial delivery plungers that take over the supply of fuel and thereby generate high pressure. The diameter number of the delivery plungers determines the fuel delivery rate. The short, direct flow of force within the cam drive produces a certain amount of resilience and, hence, a very rigid system that allows high injection pressure.

The fuel is distributed to the engine cylinder via the rotating ignition distributor shaft in which the controlling solenoid valve needle is centrally located. The forcegenerating actuator solenoid lies stationary in the distributor head. The needle is, therefore, geometrically separated into two parts. The sealed seat and the sealing part of the needle are in the rotating ignition distributor shaft. The magnetic force is transmitted by the external needle part to the concomitantly rotating needle part.

In a currentless state, the high-pressure valve is opened by spring force; the pump area can thereby fill the radial pistons with fuel via the low-pressure circuit. After current is applied, the valve closes and the high-pressure delivery begins. The timing device basically has a design similar to the axial piston distributor pump; however, the dimensions are adapted to the increased requirements.

The solenoid valves for fuel quantity and start of delivery are controlled analogously to the axial piston distributor pump via the pump ECU that, in turn, receives the required information via the increment angle time signals as described above. Because of the high fuel delivery rate of this pump, a so- called return-flow throttle valve in the area of the pump outlet is usually sufficient; i.e., it is an open system. Hence, the pump and line do not have to be joined by a hermetic seal between the individual injections into the engine cylinder. The radial piston pump is used in engines ranging from passenger car engines to heavy-duty engines.

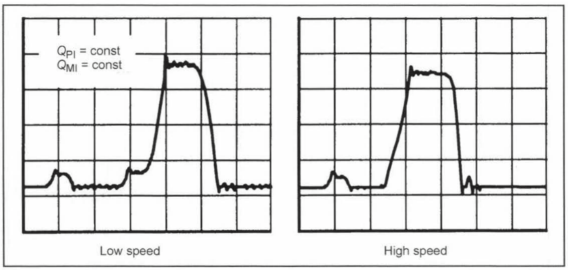

Whereas conventional distributor injection pumps with edge control are not suitable for generating preinjections by interrupting the supply phases, this is possible with solenoid-valve-controlled systems. Figure 12-36 shows the nozzle needle stroke of an injection system with a solenoid-valve-controlled radial piston pump when using a two-spring nozzle-holder assembly. At low and high speeds, we clearly see the preinjection generated by repeatedly switching the solenoid valve. In the case of low speeds, we see the rate-of-discharge curve formed by the two-spring nozzle-holder assembly.

Fig. 12-36. Preinjection realized with a radial piston distributor injection pump in connection with a two-spring nozzle-holder assembly

Common to all distributor injection pumps is that the valve gear is exclusively lubricated by the fuel in contrast to individual injection systems and inline fuel injection pumps. In the latter two systems, the valve gear, i.e., the combination of the cams and tappets is lubricated by engine oil and is, hence, tribologically insensitive in comparison to the fuel-lubricated distributor pump valve gear. The utilized diesel fuel must, therefore, meet a minimum lubrication standard. The new fuel standard DIN EN 59010 established in the 1990s requires this.

Date added: 2024-11-26; views: 450;