Systems with Injection-Synchronous Pressure Generation

The main feature of injection systems with injection- synchronous pressure generation is that the pressure generation and the fuel delivery or injection occurs individually at the right time for each engine cylinder; i.e., the pressure is generated at the same rhythm as the engine ignition sequence. Individual pump systems, inline fuel-injection pumps, distributor injection pumps, and line-free pump nozzle systems are based on this principle. The metering can be done by edge control (mechanically or electronically controlled) or by electrically actuated control valves (see also Section 12.5.1).

Individual Pump Systems with a Line. In addition to inline fuel injection pumps, the individual fuel injection pump system shown in Fig. 12-29 with mechanical control is one of the oldest diesel injection systems. This system is characterized in that the drive for the pump plunger is provided by special cams that are on the camshaft for the valve control of the engine.

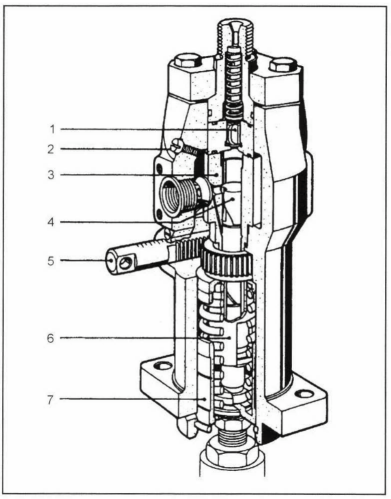

Fig. 12-29. Mechanically controlled single-plunger fuel injection, individual injection pump for large engines: 1, Pressure valve; 2, Vent screw; 3, Pump cylinder; 4, Pump piston; 5, Control rack; 6, Control sleeve; 7, Guide bushing

This design permits the use of individual injection pump systems (also frequently termed plug-in pumps) only for engines with bottom-mounted camshafts. The system is, therefore, not suitable for modem, high-speed passenger car diesel engines whose valves are controlled exclusively by overhead camshafts. The main areas of use for mechanically controlled individual pump systems are, therefore, small engines, engines for construction machinery, and stationary engines, as well as large engines for diesel locomotives or ship engines.

The attainable injection pressures for large engines range up to 2000 bar. For ship engines, special designs for heavy oil operation are available. The long life and reliability required in these cases lead to a very robust construction with sealed cylinders on one side, so-called blind-hole elements.

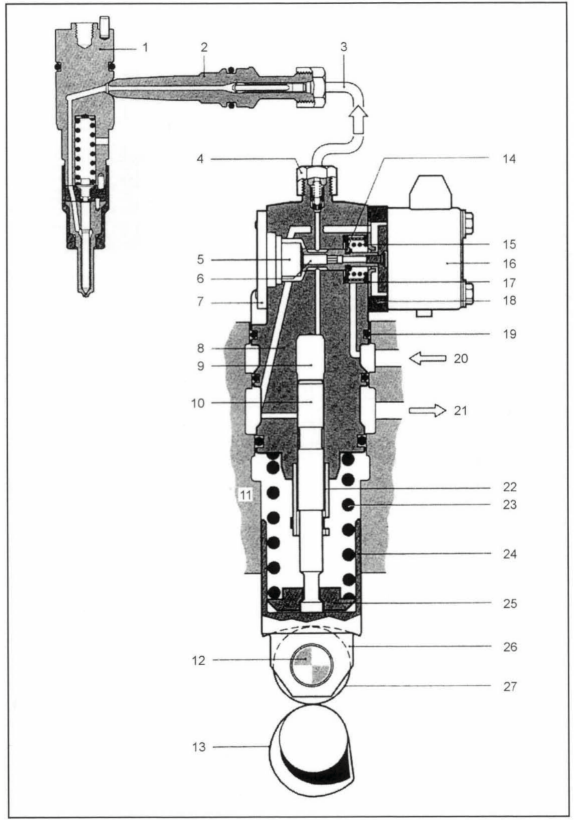

A great deal of engineering is required to freely adapt the start of delivery and, hence, fuel injection. Subsequent developments have therefore produced the solenoid valve controlled individual pump system, the pump line nozzle (PLN) system, and the unit pump system (UPS) or electronic unit pump (EUP). As a result of the short fuel injection tubing between the individual pump and the nozzle-holder assembly, the demands are slight regarding the adjustment of the beginning of delivery, and this can be flexibly accomplished by controlling the start for the solenoid valve on the delivery cam. These systems are, therefore, useful for high-speed commercial vehicle engines (Fig. 12-30). In addition, there is a greater need for freely adjusting the start of injection in large engines.

Fig. 12-30. Pump line nozzle (PLN) or unit pump system (UPS) for commercial vehicle engines. 1, Injection nozzle holder assembly; 2, Delivery connection; 3, High pressure line; 4, Connection; 5, Lift stop; 6, Solenoid valve needle; 7, Plate; 8, Pump housing; 9, Hoch pressure chamber (element chamber); 10, Pump plunger; 11, Engine block; 12, Roller tappet bolt; 13, Cam; 14, Spring seat; 15, Solenoid valve spring; 16, Valve housing with coil and magnet core; 17, Armature plate; 18, Intermediate plate; 19, Seal; 20, Fuel feed (low pressure); 21, Fuel return; 22, Pump plunger retainer; 23, Tappet spring; 24, Tappet body; 25, Spring seat; 26, Roller tappet; 27, Tappet roller

Today, unit pump systems attain maximum injection pressures of approximately 1800 bar with a potential of 2000 bar. The unit pump system is a development of the edge-controlled plug-in pump for the cam-time-controlled electronic individual pump system.

Inline Fuel Injection Pumps. The elements of the inline fuel injection pump consisting of the pump barrel and pump plunger and corresponding to the number of available engine cylinders are in their own housing in high-speed aluminum engines. The pump plungers are moved by the pump’s own camshaft that is driven by the timing gear drive of the engine. The fuel is metered exclusively through edge control by rotating the pump plunger. Each pump plunger bears an angled timing edge, so that a different delivery stroke and, hence, a different amount of injected fuel is delivered or can be set in connection with the cylinder-side, fixed spill port as a function of the angular position of the pump plunger.

The entire plunger stroke remains constant and corresponds to the cam pitch. The plunger is rotated by a control sleeve that mates with a laterally movable control rack. The control rack is moved by the governor connected to the injection pump. The governor can be either a mechanical governor that primarily shifts the control rack depending on the speed and, in particular, provides full-load speed regulation or an electronic governor that acts on the control rack by using an electromagnetic actuator mechanism. To adapt the injected fuel quantity to the wide variety of operating conditions, add-on modules are required for mechanically controlled pumps such as a charge pressure-dependent full-load stop, and temperature and quantity- dependent adjustors of the injected fuel quantity.

To reliably supply the pump elements with fuel, a low-pressure supply pump is usually mounted to the inline fuel-injection pump that is actuated by a special cam on the pump’s camshaft. The supply pump feeds fuel to the fuel gallery of the inline fuel injection pump at pressure of up to approximately 3 bar. At the high pressure exit of the inline fuel injection pump, a pressure valve separates the high- pressure area in the pump from the fuel injection tubing and the nozzle-holder assembly; therefore, after the line and nozzle system injects the fuel, the fuel in the system remains under pressure (i.e., a certain amount of static pressure remains). In addition, a return-flow throttle valve is frequently integrated in this pressure valve that prevents undesirable secondary injections at only a slight injection pressure.

Similar to the situation with mechanically controlled individual injection pumps, inline fuel injection pumps require a comparatively great deal of engineering to freely adapt the start of delivery. The speed-related control of the start of delivery can be achieved with a front-end timing device. This functions with the help of flyweights and suitable kinematics to yield a phase displacement between the pump camshaft and the engine crankshaft. A simple load-dependent control of the start of delivery is occasionally enabled by a top timing edge on the pump plunger. Hydraulic front-end timing devices are also used that can change the start of delivery in relation to both load and speed within certain limits. Despite these various solutions, the absence of a freely adjustable start of delivery is a disadvantage in conventional inline fuel injection pumps. This led to the construction of the control-sleeve pump.

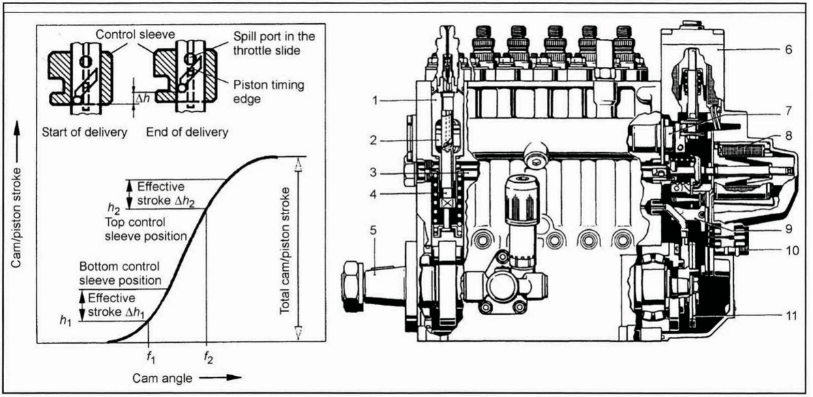

Figure 12-31 shows a section of a pump element of a control-sleeve inline fuel injection pump. Its main feature is that it can move in the area of the piston timing edge of the pump barrel (control sleeve). This permits the adjustment of the plunger lift to port closing, i.e., the piston path until the inlet passage for the fuel. A small plunger lift corresponds to an early start of delivery; a large plunger lift corresponds to a late start of delivery. The height of the control sleeves of the individual pump elements are changed by a common actuator shaft. The actuator shaft, as well as the control rack necessary for fuel metering, are activated by two separate, electromagnetic actuator mechanisms.

Fig. 12-31. Control-sleeve inline fuel injection pump. Left: Functional principle for varying the start of delivery. Right: Pump with electromagnetic actuator mechanisms: 1, Pump barrel; 2, Control sleeve; 3, Control rack; 4, Pump plunger; 5, Camshaft; 6, Start-of-delivery actuator solenoid; 7, Control-sleeve setting shaft; 8, Rack travel actuator solenoid; 9, Inductive control rack travel sensor; 10, Plug-in connection; 11, Disk to block start of delivery and part of the oil return pump

The fuel is metered in control-sleeve pumps like conventional inline fuel injection pumps or conventional individual pump systems. In comparison to standard inline fuel injection pumps, varying the start of delivery by changing the plunger lift to port closing requires higher cams. For this reason and because two actuator mechanisms are required, this pump design is used only for commercial vehicle engines. Conventional inline fuel injection pumps with mechanical or electromagnetic control are contrastingly used in all engine sizes. The large inline fuel injection pumps for ship engines are presently controlled only mechanically. The pressure range of inline fuel injection pumps extends from approximately 550 bar for the small inline pump (M-type) to approximately 1350 bar for the control-sleeve pump.

Because of greater demands for lower exhaust emissions, fuel consumption, and the related demand for maximum injection pressure in the injection system, multiple injections, and freely variable start of delivery, the inline fuel injection pump system is increasingly being replaced by solenoid-valve-controlled injection systems.

Date added: 2024-11-26; views: 382;