Injection Systems - An Overview

Tasks. The injection system is largely responsible for providing diesel engines with high exhaust quality, low fuel consumption, fast response behavior, and smooth running with little noise. Depending on the use of the diesel engine, the stated goals can assume different amounts of importance. The injection system and diesel engine are correspondingly adapted. The main tasks of the injection system are the following.

Precise metering of the fuel mass per work cycle. The load of diesel engines is controlled by metering the injected fuel mass (quality control). As a result, this must be as precise as possible to attain maximum performance; on the other hand, when the stoichiometric air-fuel ratio is approached, there is a danger of excessive noise. The more precise and stable the metering of the fuel in a full load curve (over time) is, the smaller the safety margin from the smoke limit; i.e., the engine performance can be maxed out.

The fuel quantity tolerances should be as low as possible under a full load and should not exceed approximately ±2.5%. During idling and in the partial load range (in particular, in stationary operation, i.e., when there is no intentional control), the requirements on the stability of the fuel metering are very high from cylinder to cylinder as well as from injection to injection. The deviations should be less than 1 mg/injection. It may be necessary to adapt the injected amount of fuel to each cylinder to achieve the desired smooth running.

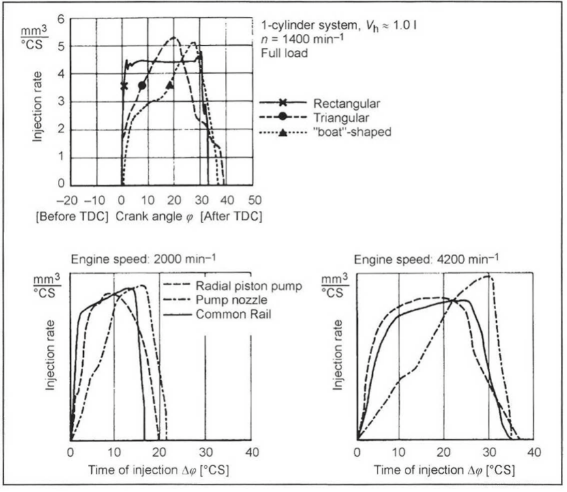

Adapting the injection rate to operation conditions. The injected fuel mass during the injection process per unit time [injection rate and its change: dm/dt = f(t)] decisively influences exhaust emissions, smooth operation and fuel consumption. In principle, the injection rate can be influenced by changing the injection orifice cross section of the nozzle and by changing the injection pressure. Despite substantial efforts, a reliable nozzle with a variable cross section has not been successfully created, which leaves only pressure modulation. The pressure can be modulated comparatively easily with a slight degree of variation by adjusting the cam shape and, hence, via the cam speed or plunger speed in the high-pressure injection pump. Pressure modulation in accumulator injection systems is presently in the developmental stage. However, injection rates can be changed to a certain extent by pressure stages in the nozzle holder. Figure 12-23 shows changed injection rates during the time for the main injection.

Fig. 12-23. Different injection curves [injection rate = f(t)] for the main injection, top3 and bottom

In general, a high injection rate at the related large amount of injected fuel at the beginning of injection produces a strong burst of combustion with a high local temperature and, hence, high NOx formation.

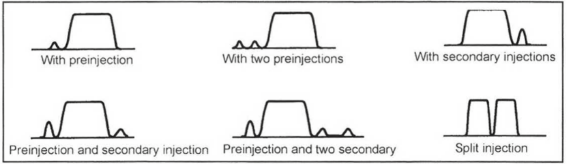

Multiple injections. Controlling the injection rate during an injection is frequently insufficient to meet requirements. Increasingly, multiple injections are required with different quantities depending on the operation point in the program map. Figure 12-24 shows a selection of conceivable multiple injection systems, some of which are in use.

Fig. 12-24. Qualitative nozzle needle stroke characteristics for multiple injections

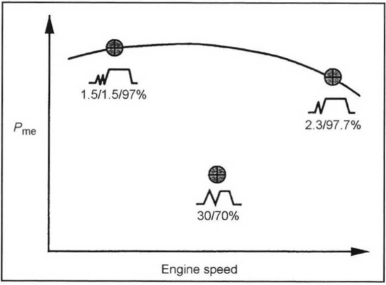

Figure 12-25 shows multiple injections at the optimum operating point and their share of fuel at three places in the program map.

Fig. 12-25. Example of optimum, operation-point-dependent multiple injections in the engine map; quantity distribution in percent

A small, reduced preinjection substantially reduces the ignition lag for the following main injection and can, hence, soften the combustion characteristic that reduces combustion noise. A secondary injection under high pressure and, hence, with a well-prepared jet is able to oxidize the soot generated during preinjection or increase the exhaust temperature given a corresponding exhaust aftertreatment system, e.g., to regenerate the particle filter. In addition, secondary injection can support the supply of uncombusted hydrocarbons to subsequent exhaust aftertreatment.

Minimum injection. In connection with multiple injections, in particular, where the preliminary and secondary injections range from approximately 1 to 3 mg per injection, e.g., in passenger car engines, the need for precisely metering the very small quantities increases dramatically. The injected fuel quantity tolerances should be less than 0.5 mg per injection. Since the fuel injector needles always move within the so-called ballistic area for these minimum amounts—i.e., they do not reach the mechanical stop—all the manufacturing-related tolerances strongly affect the quantity. The result is a very strong quality requirement for the fuel injectors, in particular, the nozzle needle and the injection orifice.

Adapting the injection time. A purely speed-related adaptation of the beginning of fuel supply in systems with long fuel injection tubing is insufficient, as has been known for a long time. Even systems without injection tubing or with electronically controlled injectors require a freely settable injection start from early (as in cold starts) to late in certain areas of the program map to reduce nitrogen oxides. Within other operating ranges, the optimum setting for fuel consumption is desirable. In addition, the times between the start of injection can be individually adjusted for multiple injections. The precision of the beginning of injection should be < ± 1° crankshaft angle.

Flexible adaptation to operating and environmental conditions. In addition to the cited main tasks, a modem injection system reacts flexibly to dynamic processes depending on the air mass. For example, when accelerating under a full load, the fuel quantity should be adapted only to the dynamically measured air mass to avoid undesirable smoke emissions. When the engine speed has been reached, the quantity of fuel is reduced corresponding to the use of the diesel engine to protect it from excess speed (full-load speed regulation). Within the bottom operating range, the engine is operated at the lowest possible speed both stably and nearly load independent.

The respective amount of required fuel also is adapted to quickly heat the engine depending on the environmental and fuel temperatures. The amount of fuel needs to be adapted to elevation as well. For example, at a high elevation above sea level, the amount of fuel under a full load should be reduced because of the lower air density to limit smoke. When the engine is overrunning, a ramplike increase in the amount of injected fuel when the speed drops below the idling speed is needed for the engine to “catch up” when idling. The injection masses need to be adapted to the respective operating conditions depending on the charge pressure and exhaust gas recycling.

These multifaceted and sometimes interrelated tasks and demands on injection systems can be handled only by electronically controlled systems. Mechanically controlled systems with edge-controlled fuel metering cannot meet these demands, or can only at the cost of substantial compromises. In uses where the cited greater demands are not as important, in particular on dynamic behavior, these mechanical, robust systems are still satisfactory. Edge-controlled systems have largely been abandoned in vehicle engines that have to meet stringent exhaust laws and simultaneously use as little fuel as possible under dynamic conditions.

Date added: 2024-11-26; views: 373;