Basic Housing for Keeping Amphibians

The most commonly used materials for amphibian enclosures are glass and plastic. Plastic has the advantage that it can be easily cut and drilled, such as is done to install plumbing and create ventilation holes. A major disadvantage of plastic is that it scratches easily. In time, this may obscure viewing into the tank. Scratching also roughens the wall surfaces, making it easier for small climbing food insects to escape. Plastics also are more absorbent than glass, and may pick up and later leach out disinfectants or other contaminants deleterious to the cage inhabitants. Many plastics become yellow and brittle after prolonged exposure to UV light yet such light is commonly used over amphibian cages for its possible health benefits to the animals (see Section 5.6.4, Lighting).

Glass is not as easily drilled as plastic, but glass companies and some aquarium stores will drill holes in the walls and floor of untempered glass tanks for a small fee.

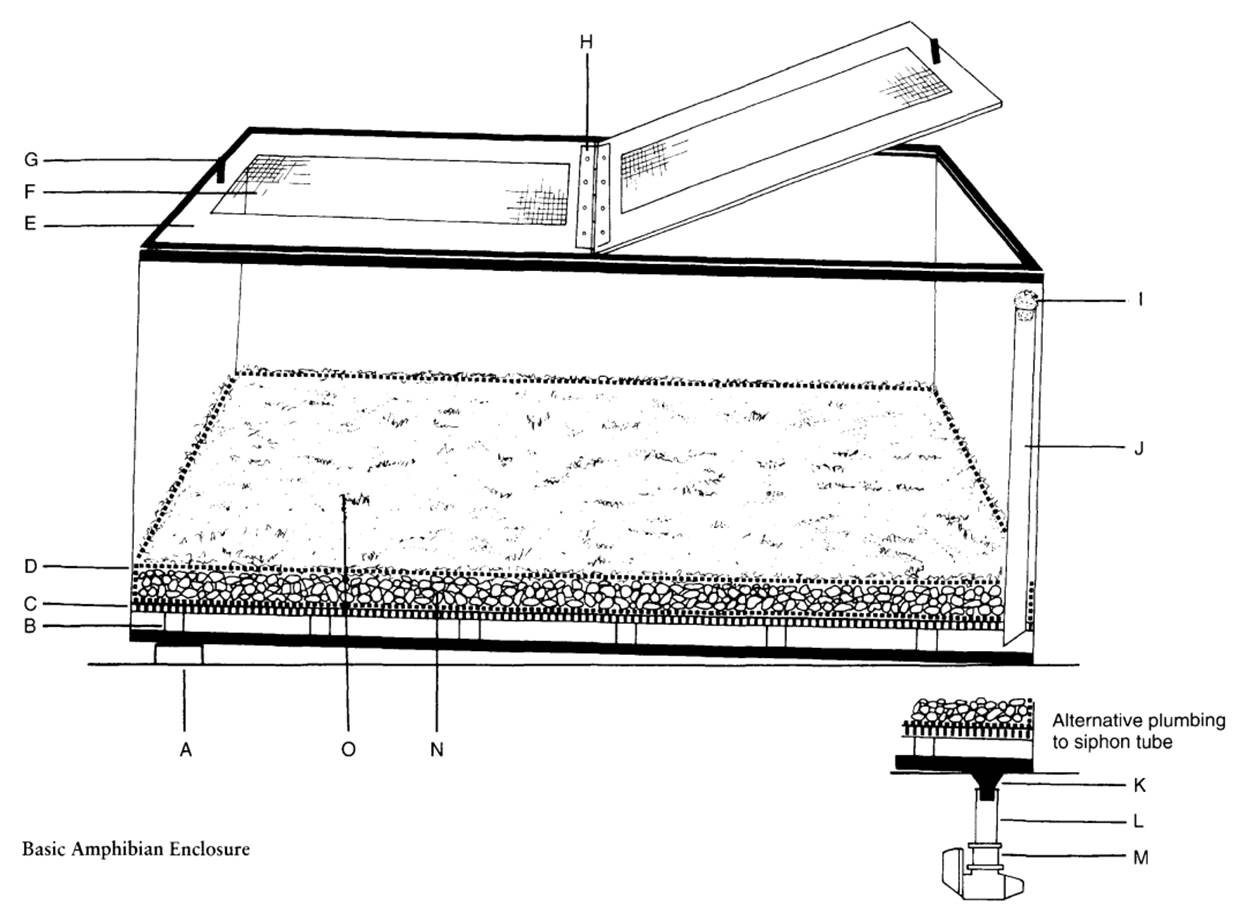

At NAIB, plumbed glass aquariums and plumbed plastic containers (e.g., Small Pal Pens®, Rolf C. Hagen USA Corp., Mansfield, MA) are used to house most of the amphibian collection (approximately 50 species of anurans, 1800 specimens). The tank dimensions and enrichment vary with the particular habitat requirements of the housed specimens, but the same basic tank design is used throughout the collection (Figure 5.1). It is applicable to a wide range of amphibians, as described below.

Figure 5.1. Lateral view of the unfurnished basic amphibian enclosure used at the National Aquarium in Baltimore. A. cross section of nominal 2.5 X 5 cm (1” X 2”) board supporting the rim of the tank, tipping it toward the drain. B. plastic biofilter rings 2.5 cm outer diameter (1” OD) used as pilings for the false floor, sections of PVC pipe can be substituted as pilings. C. false floor made from a sheet of plastic “egg-crate” or light-diffusing panels. D. single layer of fiberglass window screening with 2.5 cm (1 ”) border turned up and pressed against the tank wall by overlying gravel, or sealed to the tank wall with silicone rubber. E. two-panel lid made from 2.5 cm (1”) wide vinyl window screen framing. F. removeable fiberglass window screen panel. G. nylon nut and bolt lid handle; other plastic or stainless steel hardware can be substituted.

H. all plastic piano hinge attached with nylon nuts and bolts; stainless steel hardware may be substituted. I. aquarium filter floss used as a stopper in the siphon well, to keep animals and debris out. J. clear plastic siphon well permanently sealed in place with silicone rubber; the well extends below the false floor, to allow debris and dirty water to be siphoned out of the subfloor zone using a removeable soft plastic hose fed down the well. N. layer of pea gravel. O. moist cover of rehydrated dried sheet moss or sphagnum moss. (Inset) As an alternative to using a siphon well, the bottom of the tank may be plumbed using a bulkhead system (K, L, M). A hole must be drilled in the bottom glass of the aquarium to use this system.

K. A removable bulkhead system can be installed and connected to a drain hose. Alternatively, a nylon or polyethylene male connector/reducer tube fitting with a 2.5 cm (1.0”) outer diameter threaded end can be epoxied into the drain hole and cut flush with the inside floor of the tank; the tapered end press-fits into the flexible drain hose; a plastic garden hose connector can be substituted for the male connector/reducer tube fitting. L. flexible vinyl tubing 1.7 cm (11/16”) outer diameter; 1.3 cm (0.5”) inner diameter). M. plastic stopcock. (Sandy Barnett)

NAIB uses custom-made hinged lids fashioned from vinyl window screen framing over all amphibian cages (see Figure 5.1), except for the plastic “Pal Pens,” which come with snap-on plastic lids. The vinyl framing is relatively weather-resistant and nonabrasive. The frames are inset with removable panels of fiberglass window screening. The panels allow fresh air to enter the cage and allow the transmission of potentially beneficial ultraviolet (UV) radiation from overhead sources. By using hinged lidsб rather than one-piece construction, only part of the cage needs to be uncovered during servicing which helps to minimize the chances of escape by amphibians and food insects.

All-aluminum window screen framing may be substituted for vinyl framing, which is not readily available in stores, but any metal should be used with caution in an amphibian enclosure due to the risks of metal toxicoses. Standard fiberglass window screening will pass small in sects (e.g., fruit flies), but screening that is fine enough to hold back very tiny insects is prohibitively expensive. Galvanized hardware cloth lids and lids made with aluminum window screening are not recommended since they can easily abrade the delicate skin of amphibians. There is also the possibility that galvanized metal screens will leach harmful levels of zinc.

Custom-cut sheets of clear thermoplastic (e.g., Plexiglas®, Lexsan®) can also serve as lids. Numerous small holes should be drilled in the plastic for ventilation. Care should be taken that the holes are perfectly smooth on the inside surface of the lid for the animals’ safety. The major disadvantages of solid plastic or glass lids is that they significantly reduce ventilation (see Section 5.6.2, Humidity), and they screen out potentially beneficial UV light (see Section 5.6.4, Lighting). Also, some plastics tend to warp over time, which may create gaps of sufficient size to allow the inhabitants to escape.

There are some commercially available plastic vivarium tops that are designed to tightly fit onto the top of all glass aquariums (e.g., “Pal Pen Tank Lids,” distributed by Hagen). These lids fit well and, in general, provide good ventilation and illumination. However fruit flies and small insects may be able to crawl through the ventilation slits.

Date added: 2025-02-17; views: 446;