Earthworks and Foundation Structure

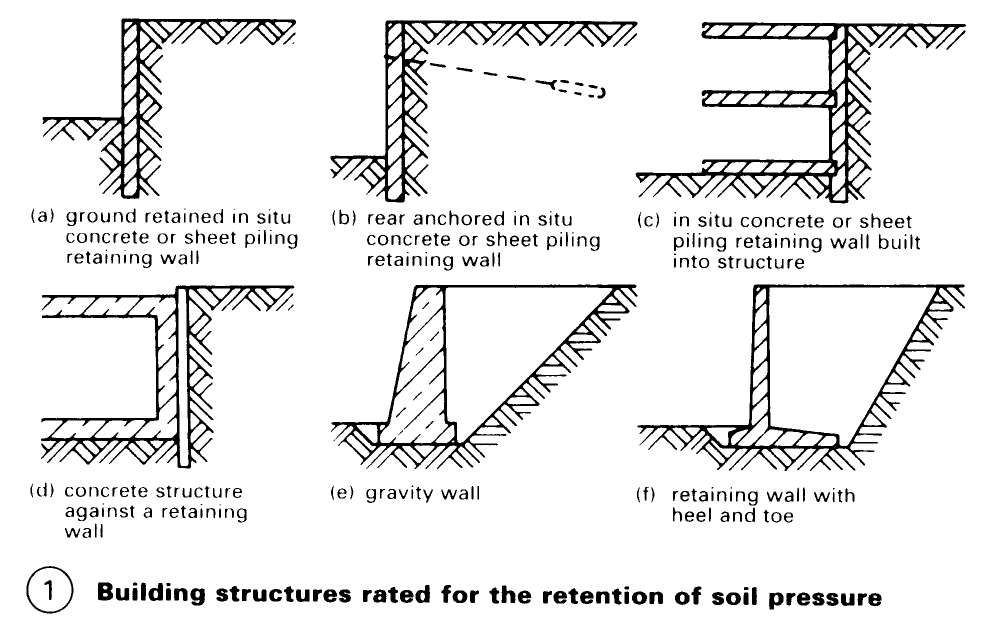

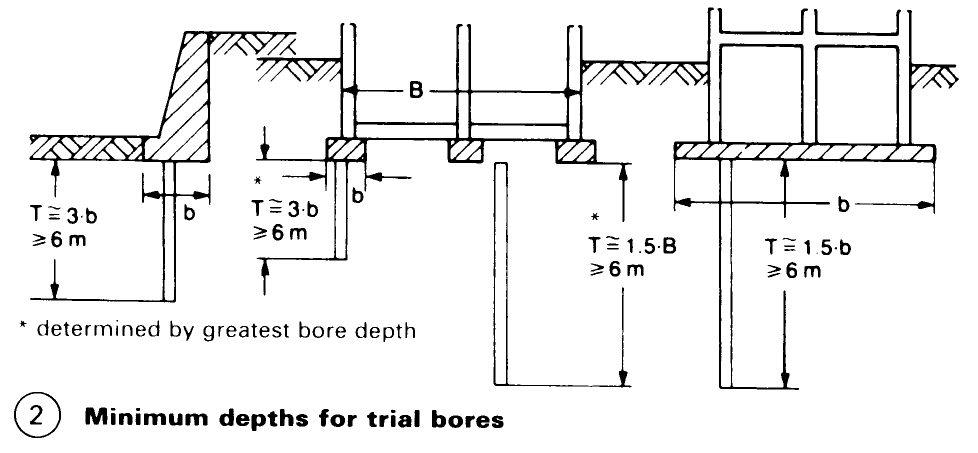

To calculate the active soil pressure on retaining walls – (1) and the permissible loading sub-soil, the type, composition, extent, stratification and strength of the ground strata must be known. Where local knowledge is inadequate, trial excavation and boreholes are necessary (separation of the bore holes < 25m). For pile foundations, the bore depths should extend to the foot of the piles - (2).

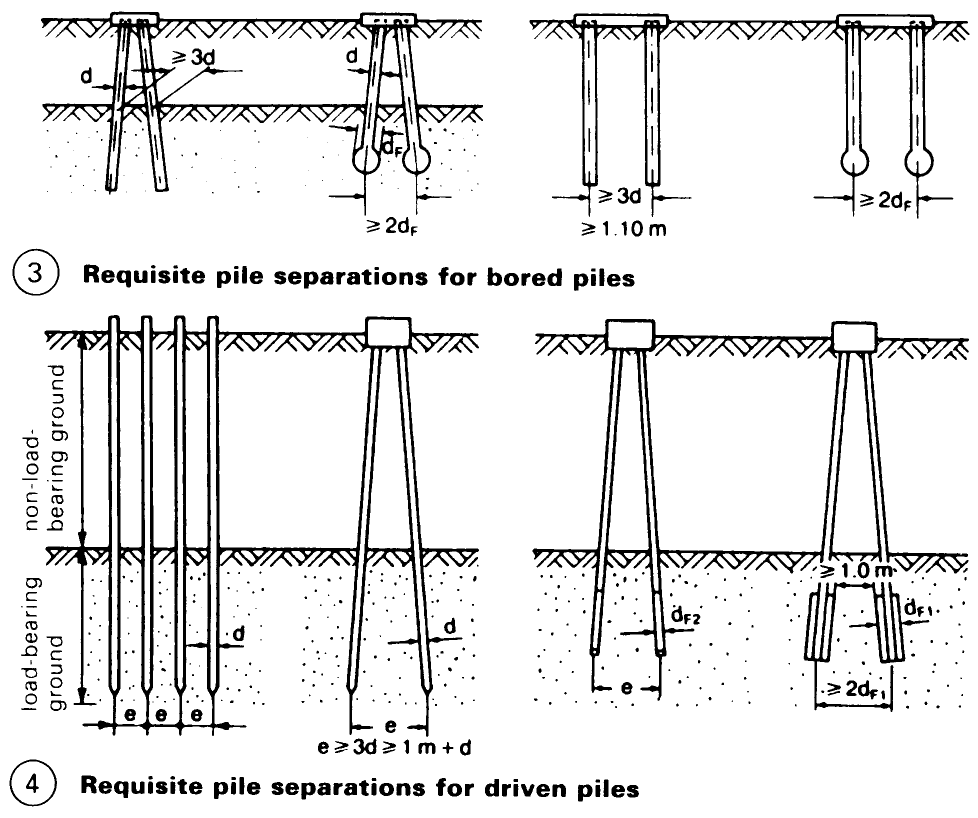

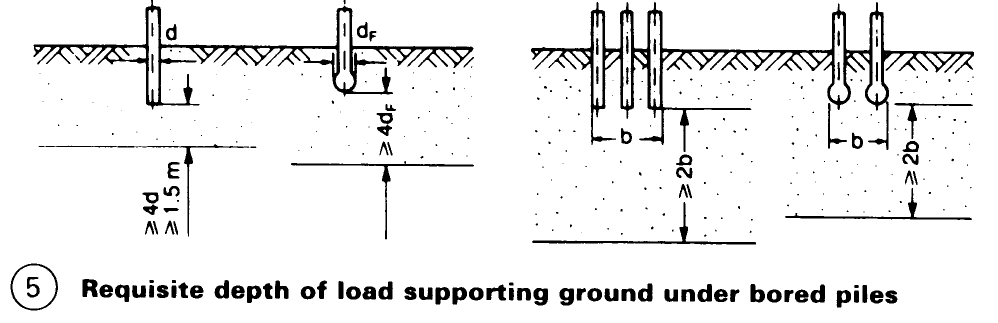

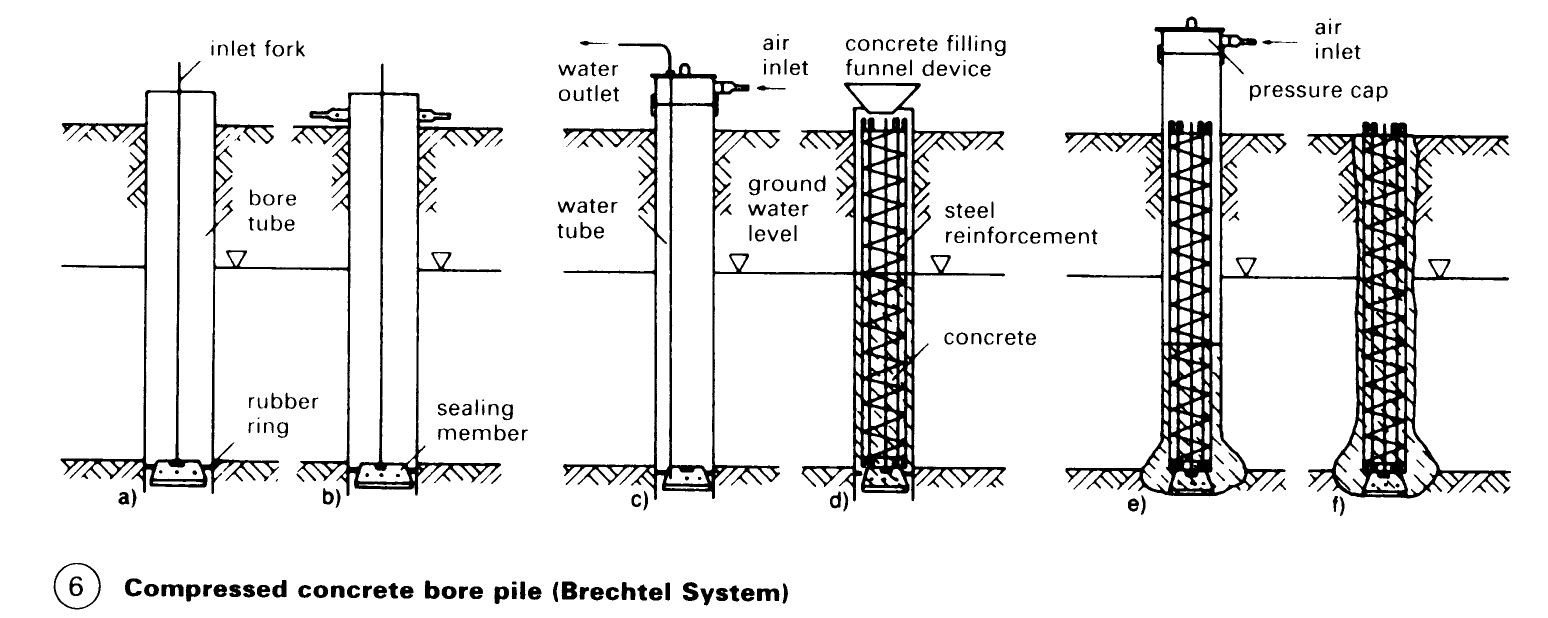

According to the method of measurement, these depths can be reduced by a third (T = 1.0B or 2 x pile diameter, but >6.0m). For the required pile separations for bored piles - (3); for driven piles – (4). The stated values do not apply to load-bearing plugged and bored pile walls. For the requisite depth of the load-bearing ground under bored piles - (5); for compressed concrete bored piles, Brechtel System – (6).

Pile foundations: Loads can be transmitted by the piles to the load-bearing ground by surface friction, end bearing or both bearings; the type of load transfer depends on the building site and the nature of the piling. Bearing pile foundations: load transmission takes place at ends of the piles onto the loadbearing ground and/or through skin friction. Suspended pile foundations: the piles do not extend downwards until the ends are on the load-bearing region. Weak load-bearing layers are compacted by pile driving.

Type of load transfer: Friction piles essentially transfer the load through surface friction via the load bearing region around the circumference of the pile. End bearing piles: the load is principally transmitted by the pile end on to the bearing stratum; in this case, surface friction is not significant. The permissible end pressure is significantly increased in some types of pile by widening the bases of the piles.

Position of the piles in the ground: Foundation piles are in the ground over their whole length. Retaining and projecting piles are free standing piles, whose lower portions only are below ground; the tops of these piles are exposed and therefore subject to buckling stresses.

Materials: wood, steel, concrete, reinforced concrete and prestressed concrete piles.

Method of insertion in the ground: Driven piles are rammed into the ground by pile driving hammers. Jacked piles are inserted by pressure. Bored piles are inserted by way of a bore hole. Screwed piles are inserted by rotation. With driven tube piles, a steel tube former is driven into the ground and withdrawn as the concrete pile is cast in situ. A distinction is made between piles which compact the ground, pierce it, or pass through a hole in it.

Type of loading: Axially loaded piles. Bearing piles are subject to compressive stresses - the load being transmitted through point pressure and surface friction. Tensile piles are subjected to tensile stress with loads transmitted through surface friction. Horizontally loaded piles. Retaining or projecting piles are subject to bending stresses, e.g., horizontally loaded large bore piles, sheet piles.

Manufacture and installation: Prefabricated piles are made in finished sections and delivered to the point of use, and driven into the ground by hammering, pressing, vibrating, screwing or by inserting in ready-prepared bore holes. In situ piles are created in a hollowed-out chamber in the ground, such as bored piles, tube piles, auger piles and cylinder piles. Mixed foundation piles are assembled from in situ and prefabricated parts. In situ piles provide the advantage that their length is not critical pre construction, and can be designed on the basis of compaction results, and examination of cores of the ground strata obtained during the boring process.

Date added: 2023-01-01; views: 819;