Tensile and Inflatable Structures. Cable Net Structures

The construction of awnings and tensile roofs is becoming more widespread. These constructions vary from simple awnings and roofs, to technically very complicated tensile structures of the most diverse types.

Materials: artificial fibre material (polyester) is used as the base fabric, with corrosion resistant and weather proof protective layers of PVC on both sides.

Characteristics: high strength (can resist snow and wind loads); non-rotting; resistant to aggressive substances; water and dirt repellent, and fire resistant.

Weight: 800-1200g/m2.

Permeability to light: from 'impermeable' up to 50% permeability.

Life: 15-20 years; all popular colour shades; good colour fastness

Workability: manufactured in rolls; widths 1-3m, usually 1.5 m; length up to 2000 running metres; cut to shape to suit structure; can be joined by stitching, welding, with adhesives, combinations of these, or by clamp connectors.

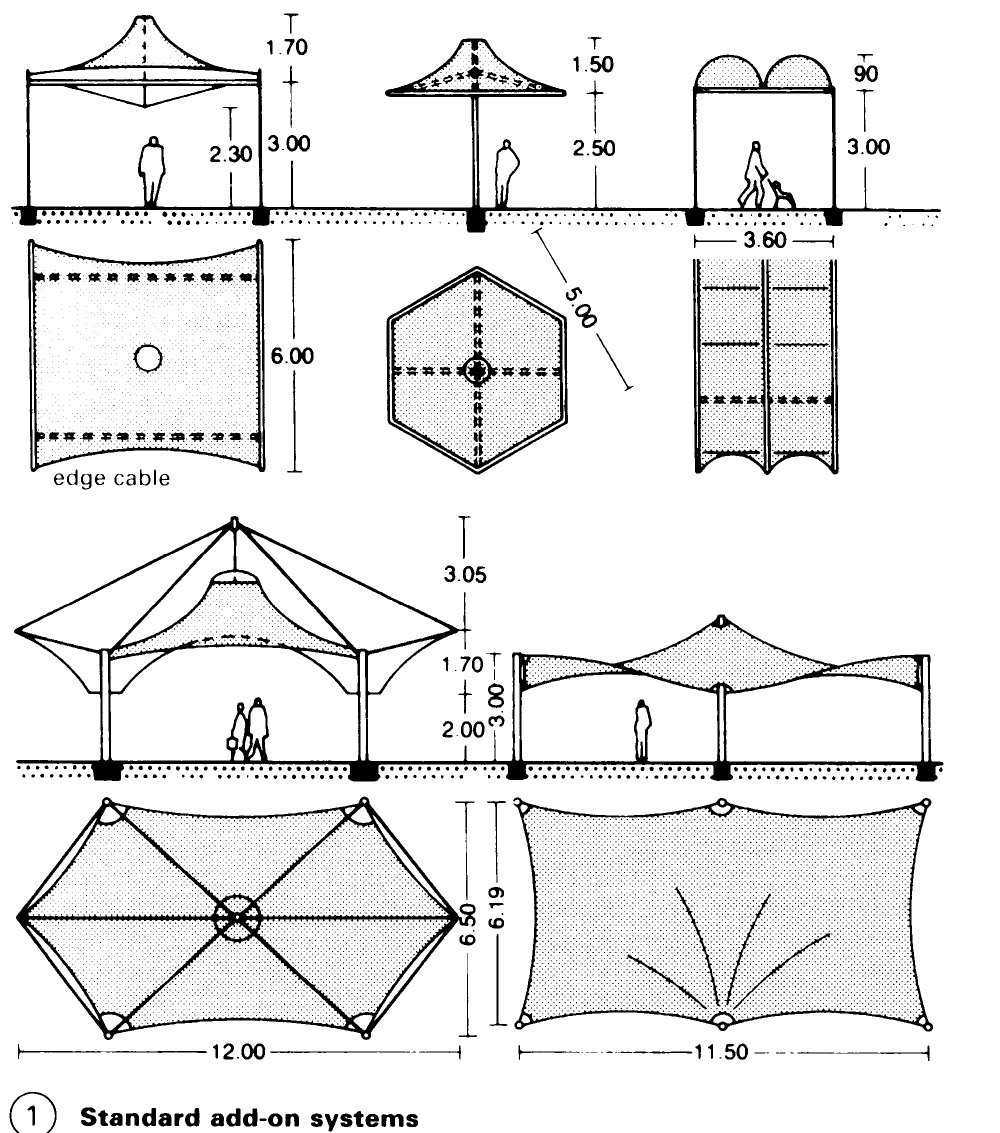

Add-on standard systems (1). Standard units allow the structure to be extended indefinitely, often on all sides. They embrace most planforms: square, rectangular, triangular, circular, polyhedra. Application: connecting passageways, rest area pavilions, shade awnings, etc.

Framed structures. A supporting frame is made from wood, steel or aluminium, over which the membrane is stretched as a protective covering. Application: exhibition halls, storage and industrial areas.

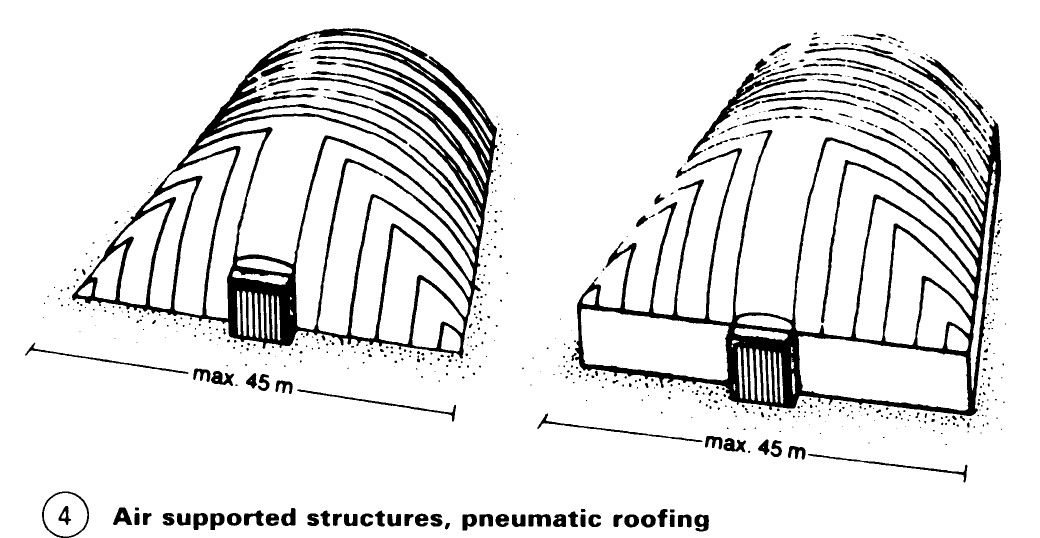

Air supported structures – (4). The structural membrane is supported by compressed air at low pressure, and air locks prevent the rapid release of the supporting air. The system can be combined with heating, and additional insulation can be provided by an inner shell (air mattress). Maximum width is 45m, with length unlimited. Application: exhibition, storage, industrial and sport halls; also as roofing over swimming pools and construction sites in winter.

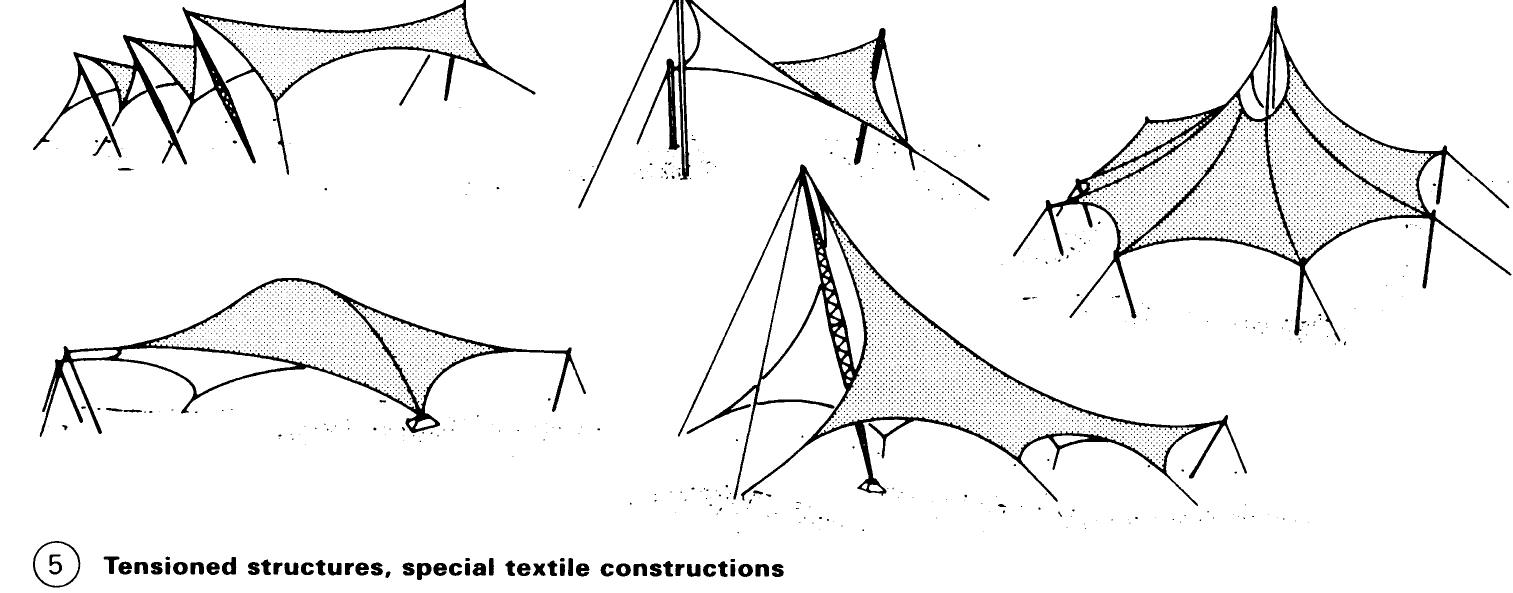

Tensioned structures – (5). The membrane is supported at selected points by means of cables and masts, and tensioned around the edges. To improve thermal insulation, the structure may be provided with additional membranes. Span can be up to more than 100m. Application: exhibition, industrial and sports halls, meeting and sports areas, phantom roofs.

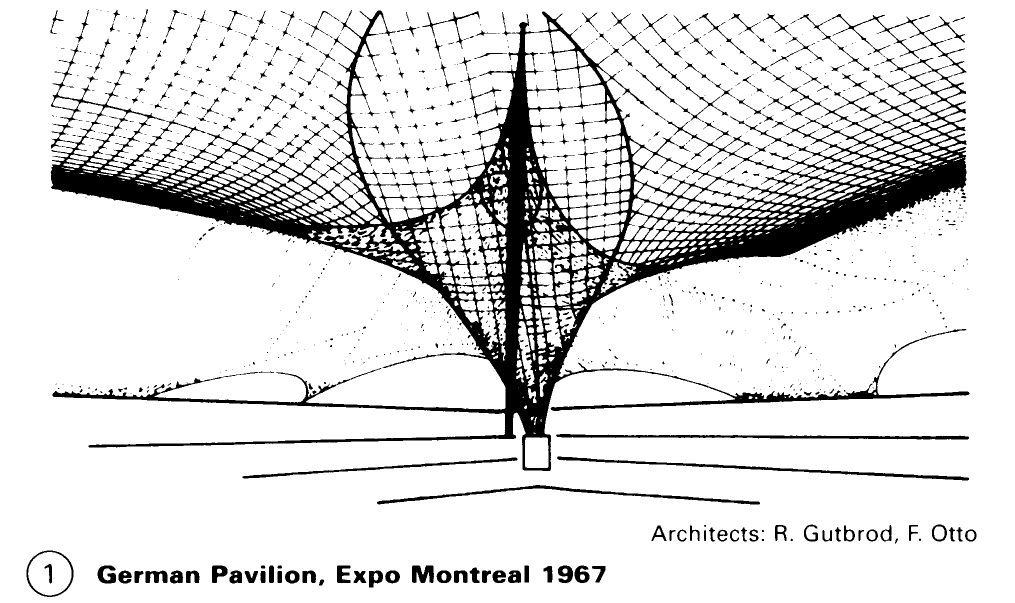

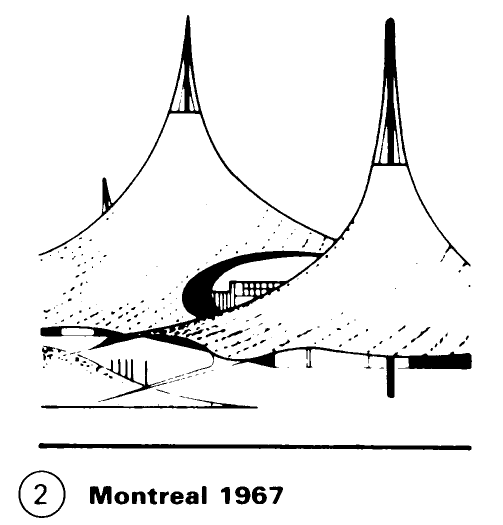

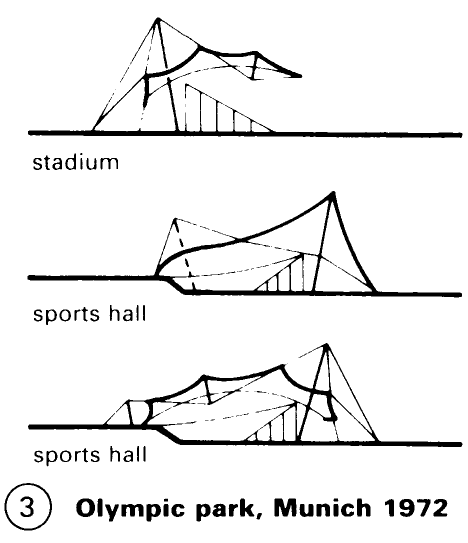

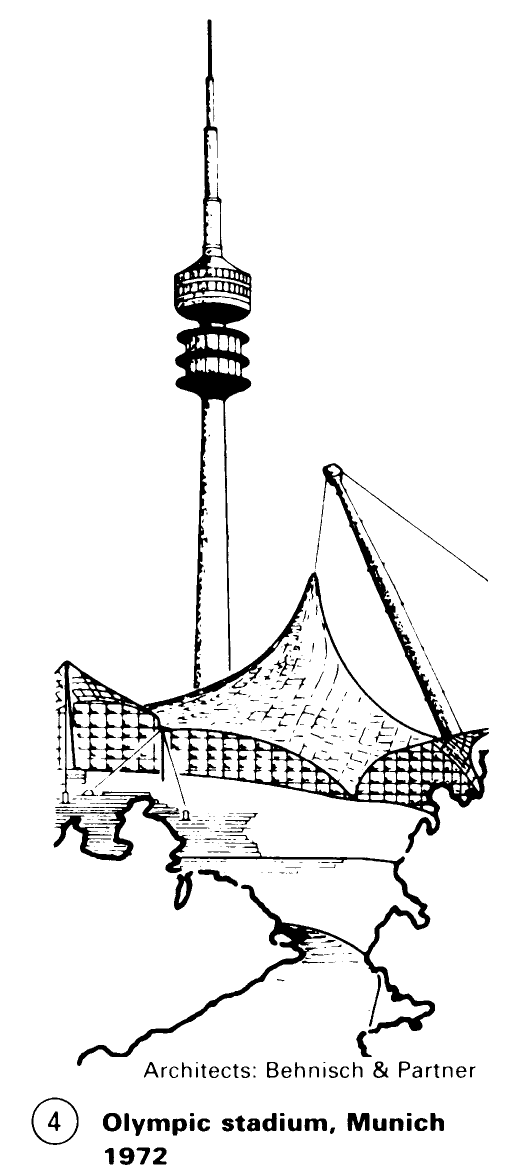

Cable Net Structures. Cable net structures offer the possibility of covering large unsupported spans with considerable ease. The German pavilion at the World Exhibition in Montreal in 1976 was constructed in this fashion – (1) + (2), the Olympic Stadium in Munich, 1972 - (3)- (8) and the ice rink in the Olympic Park in Munich – (10) – (13). An interesting example is also provided by the design for the students club for the University and College of Technology in Dortmund - (9).

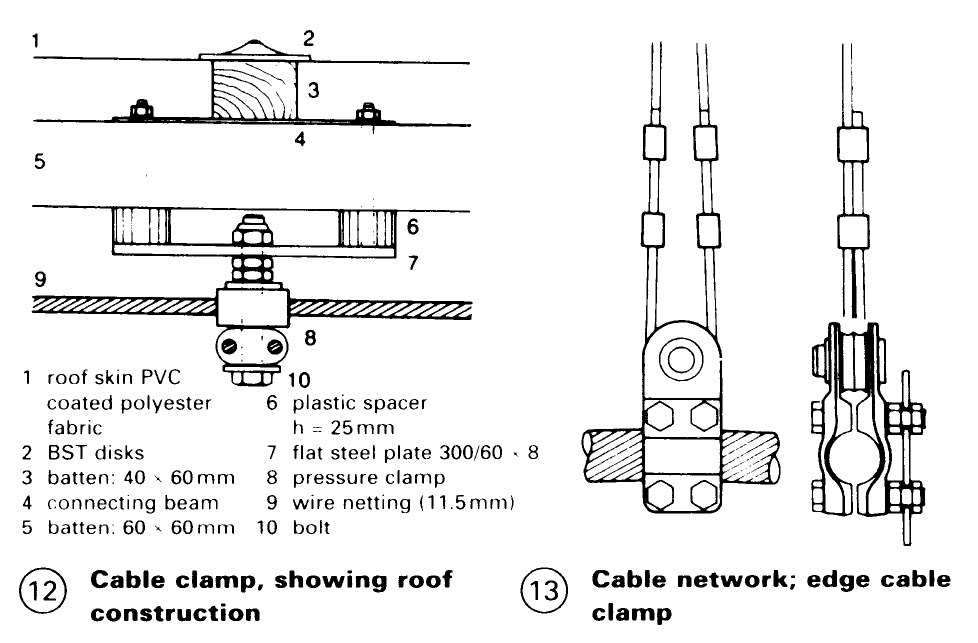

As a rule, the constructional elements are steel pylons, steel cable networks, steel or wooden grids, and roof coverings of acrylic glass or translucent, plastic-reinforced sheeting.

Cables are fastened into the edges of the steel network, the eaves, etc., and are laid over pin-jointed and usually obliquely positioned steel supports, and then anchored.

'Aerial supports', cable supporting elements which are stayed from beneath, divide up the load of the main supporting cable to reduce the cable cross-sections.

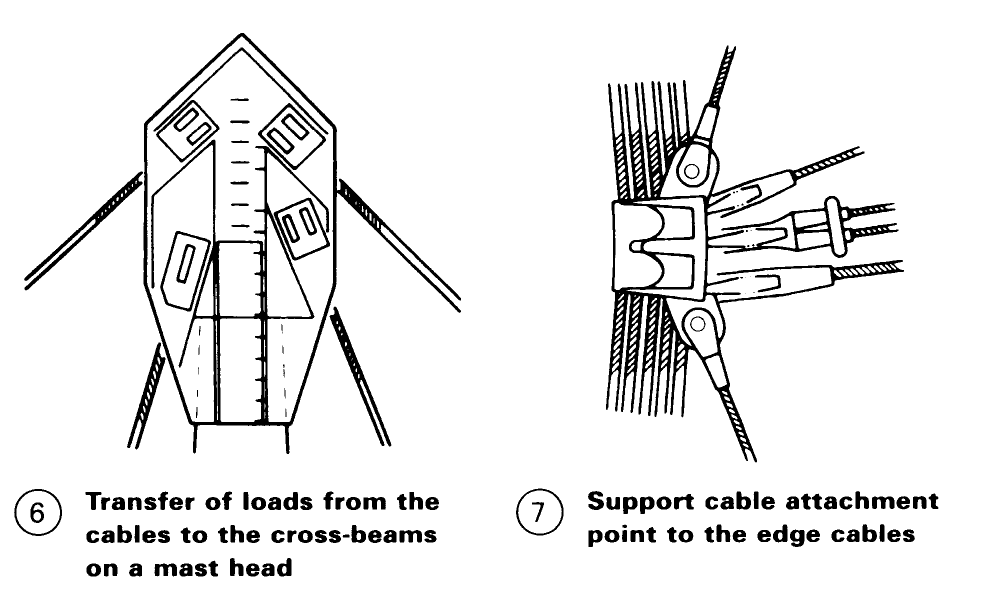

The transfer of load of the tension cables usually takes place via cast components - bolt fixings, housings, cable fixings, etc. The cable fixings can be secured by self-locking nuts or by the use of pressure clamps.

Date added: 2023-01-01; views: 817;