Rotating vane. Angled-propeller meter. Bypass meter

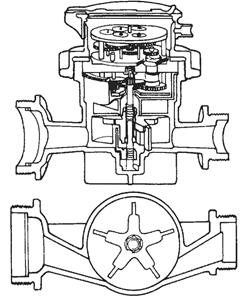

Rotating vane. This type of meter operates on the principle that the incoming liquid is directed to impinge tangentially on the periphery of a free-spinning rotor. The rotation is monitored by magnetic, or photoelectric pick-up, the frequency of the output being proportional to flow rate, or alternatively by a mechanical register connected through gearing to the rotor assembly as shown in Figure 1.22.

Accuracy is dependent on calibration, and turndown ratios up to 20:1 can be achieved. This device is particularly suited to low flow rates.

Figure 1.22. Rotating-vane type meter

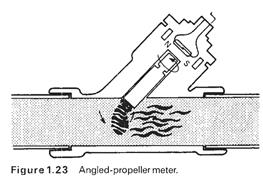

Angled-propeller meter. The propeller flowmeter comprises a Y-type body with all components apart from the propeller being out of the liquid stream. The construction of this type of meter is shown in Figure 1.23.

The propeller has three blades and is designed to give maximum clearance in the measuring chamber, thereby allowing maximum tolerance of suspended particles. The propeller body is angled at 45° to the main flowstream and liquid passing through the meter rotates it at a speed proportional to flow rate. As the propeller goes through each revolution, encapsulated magnets generate pulses through a pick-up device, the number of pulses being proportional to flow rate.

Bypass meter. In this type of meter (also known as a shunt meter) a proportion of the liquid is diverted from the main flowstream by an orifice plate into a bypass configuration. The liquid is concentrated through nozzles to impinge on the rotors of a small turbine located in the bypass, the rotation of the turbine being proportional to flow rate.

This type of device can give moderate accuracy over a 5:1 turn-down ratio and is suitable for liquids, gases, and steam. Bypass meters have been used with other shunt-meter devices, including Coanda-effect oscillatory How meters, rotameters, ultrasonic meters, and positive displacement meters and multijets.

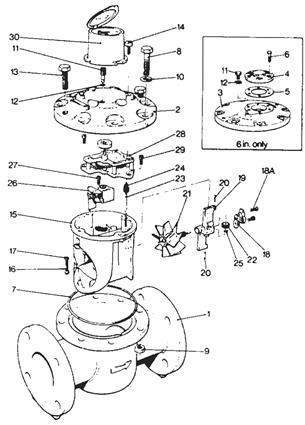

Helix meter. In this type of meter the measuring element takes the form of a helical vane mounted centrally in the measuring chamber with its axis along the direction of flow as shown in Figure 1.24. The vane consists of a hollow cylinder with accurately- formed wings. Owing to the effect of the buoyancy of the liquid on the cylinder, friction between its spindle and the sleeve bearings is small. The water is directed evenly onto the vanes by means of guides.

Figure 1.24. Helix meter, exploded view. 1. Body. 2.Top cover with regulator plug and regulator sealing ring. 3. Top cover plate. 4. Joint plate. 5. Joint plate gasket. 6. Joint plate screws. 7. Top cover sealing ring. 8. Body bolt. 9. Body bolt unit.10. Body bolt washer. 11. Regulator plug. 12. Regulator plug sealing ring. 13. Joint breaking screw. 14. Counter box screw. 15. Measuring element. 16. Element securing screw. 17. Element securing screw washer. 18. Back bearing cap assembly.19. Back vane support. 20. Tubular dowel pin. 21. Vane. 22. Worm wheel. 23.Vertical worm shaft. 24. First pinion. 25. Drive clip. 26. Regulator assembly. 27. Regulator assembly screw. 28. Undergear. 29. Undergear securing screw. 30. Register

Transmission of the rotation from the undergear to the meter register is by means of ceramic magnetic coupling. The body of the meter is cast iron, and the mechanism and body cover is of thermoplastic injection moulding. The meter causes only small head loss in operation and is suited for use in water-distribution mains. It is available in sizes from 40 mm up to 300 mm, respective maximum flow rates being 24m3/h and 1540m3/h, with accuracy of ±2 percent over 20:1 turn-down ratio.

Date added: 2023-05-02; views: 721;