Nutating-disc type. Fluted-spiral-rotor type (rotating-impeller type)

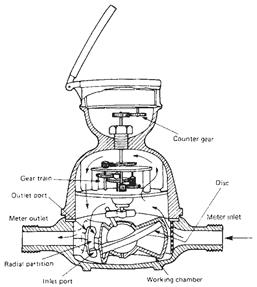

Nutating-disc type. This type of meter is similar in principle to the rotary-piston type. In this case, however, the gear train is driven not by a rotating piston but by a movable disc mounted on a concentric sphere. The basic construction is shown in Figure 1.18.

The liquid enters the left side of the meter, alternately above and below the disc, forcing it to rock (nutate) in a circular path without rotating about its own axis. The disc is contained in a spherical working chamber and is restricted from rotating about its own axis by a radial partition that extends vertically across the chamber. The disc is slotted to fit over this partition. The spindle protruding from the sphere traces a circular path and is used to drive a geared register.

Figure 1.17. Reciprocating-piston meter

This type of meter can be used for a wide variety of liquids-disc and body materials being chosen to suit.

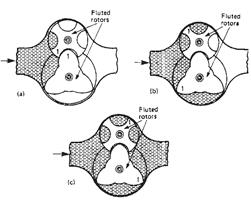

Fluted-spiral-rotor type (rotating-impeller type). The principle of this type of meter is shown in Figure 1.19. The meter consists of two fluted rotors supported in sleeve-type bearings and mounted so as to rotate rather like gears in a liquid-tight case. The clearance between the rotors and measuring chambers is kept to a minimum. The shape of the rotors is designed so that a uniform uninterrupted rotation is produced by the liquid. The impellers in turn rotate the index of a counter which shows the total measured quantity.

Figure 1.19. Fluted-spiral-rotor type of meter

This type of meter is used mainly for measuring crude and refined petroleum products covering a range of flows up to 3000 m3/h at pressures up to 80 bar.

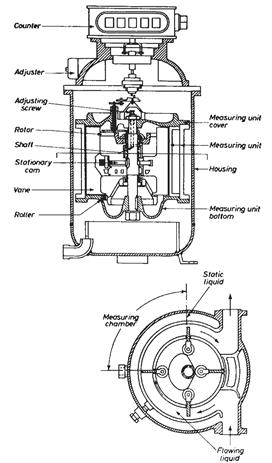

Sliding-vane type. The principle of this type is illustrated in Figure 1.20. It consists of an accurately machined body containing a rotor revolving on ball bearings. The rotor has four evenly spaced slots, forming guides for four vanes. The vanes are in contact with a fixed cam. The four cam-followers follow the contour of the cam, causing the vanes to move radially. This ensures that during transition through the measuring chamber the vanes are in contact with the chamber wall.

Figure 1. 20. Sliding-vane type meter. Courtesy, WayneTank & Pump Co

The liquid impact on the blades causes the rotor to revolve, allowing a quantity of liquid to be discharged. The number of revolutions of the rotor is a measure of the volume of liquid passed through the meter.

Rotating-vane type. This meter is similar in principle to the sliding-vane meter, but the measuring chambers are formed by four half-moonshaped vanes spaced equidistant on the rotor circumference. As the rotor is revolved, the vanes turn to form sealed chambers between the rotor and the meter body. Accuracy of ±0.1 percent is possible down to 20 percent of the rated capacity of the meter.

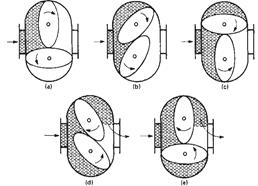

Oval-gear type. This type of meter consists of two intermeshing oval gearwheels which are rotated by the fluid passing through it. This means that for each revolution of the pair of wheels a specific quantity of liquid is carried through the meter. This is shown diagrammatically in Figure 1. 21. The number of revolutions is a precise measurement of the quantity of liquid passed. A spindle extended from one of the gears can be used to determine the number of revolutions and convert them to engineering units by suitable gearing.

Figure 1.21. Oval-gear meter

Oval-gear meters are available in a wide range of materials, in sizes from 10 to 400 mm and suitable for pressures up to 60 bar and flows up to 1200m3/h. Accuracy of ±0.25 percent of rate of flow can be achieved.

Date added: 2023-05-02; views: 658;