Maintenance and Restoration. Examples of solutions

In this example, the aim was to preserve an old wooden structure by covering it with an arched steel roof.

The multipurpose hall built in Münster in 1928 was covered over with a steel roof which was so badly damaged in the Second World War that it had to be completely renewed. However, after the war steel was too expensive to consider, so for 35 years the 37 x 80 m hall was covered only by a wooden network shell with no columns. The structure carried just its own weight, snow load or loads such as lighting platforms, and had no heat insulation.

Project requirements. The new roof skin must:

- meet heat insulation regulations;

- insulate the inside from external noises and keep internal reflected sound to a minimum.

The new structure should also:

- carry special loads, such as sporting equipment, backdrops, lighting bridges etc.;

- be sufficiently strong to be walked on;

- be able to be mounted on the existing foundations;

- allow the network construction to be maintained;

- offer planning and manufacturing times as short as possible.

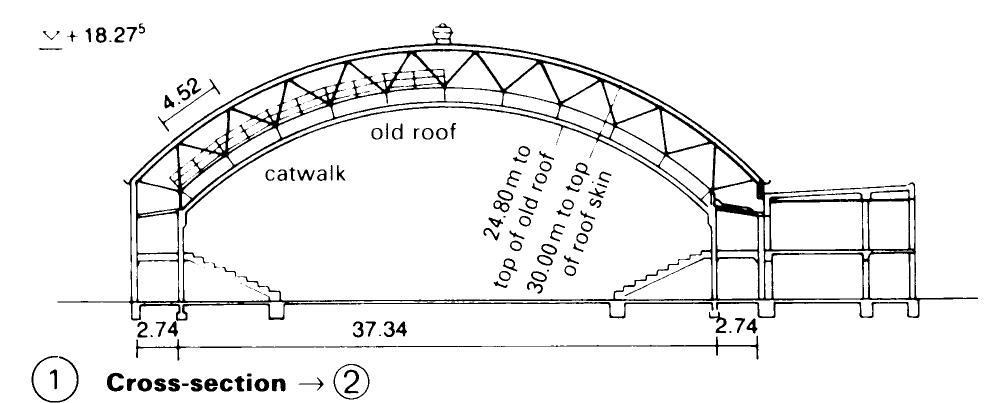

Solution. A spaceframe structure made from circular-section tubes screwed into nodes gave the required minimisation of the total weight and the existing wooden structure was suspended from this – (1)).

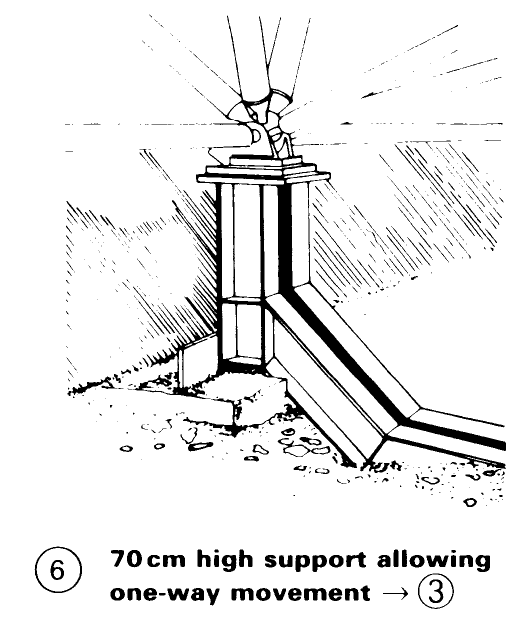

Twenty-two of these spaceframe arches are cross-linked by expanding diagonals and bridge an area of 37.34 x 80.30m. One of the two 70cm high rows of supports has sliding bearings to allow movement and the second row is designed as a pin-jointed support system - (6). Ten transverse catwalks are installed in the spaceframe – (1).

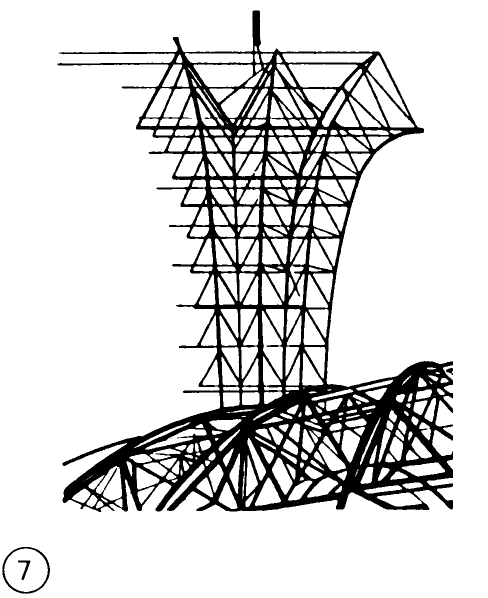

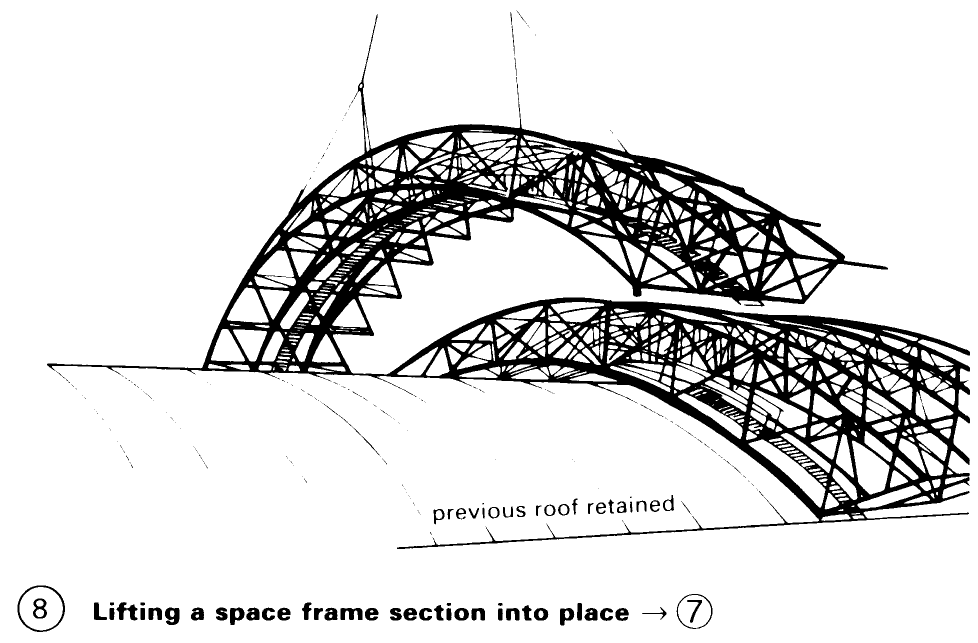

Small cranes preassembled seven large-scale structural elements, weighing up to 32t, which were then put in position in 21/2 days with a 500t crane - (7) - (8).

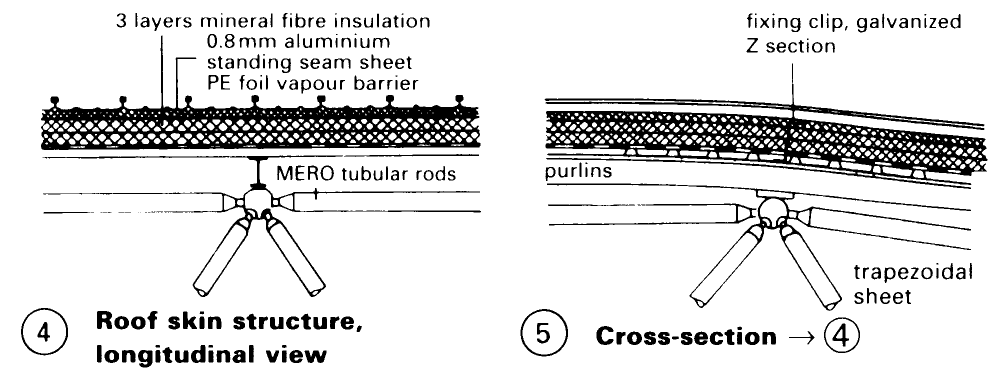

The structure is galvanized and painted with a PVC acrylic paint and a special insulation layer for corrosion and fire protection. The roof skin consists of purlins, steel trapezoidal sheets, a vapour barrier, heat insulation and aluminium standing seam sheeting to protect from rain- (4) – (5).

The parties involved were: Münsterlandhalle GmbH, Hochbauamt Münster, MERO spatial structures and numerous specialist engineers.

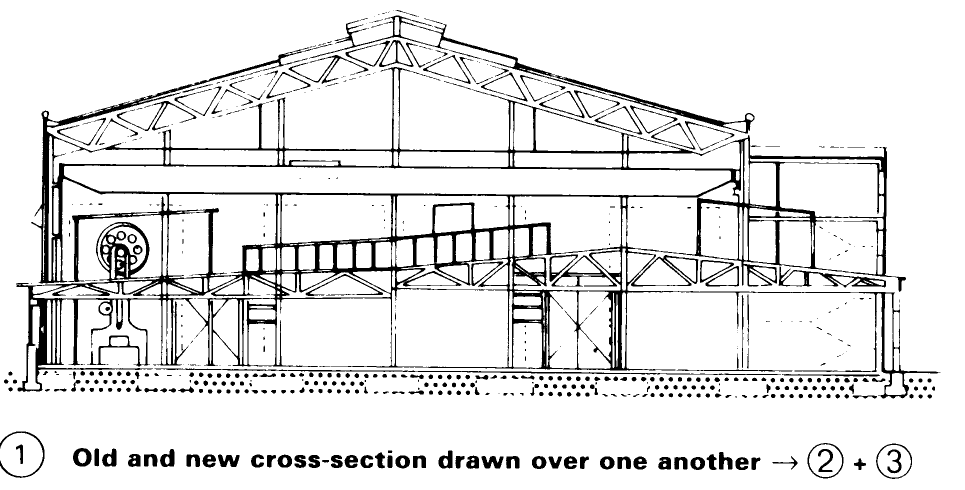

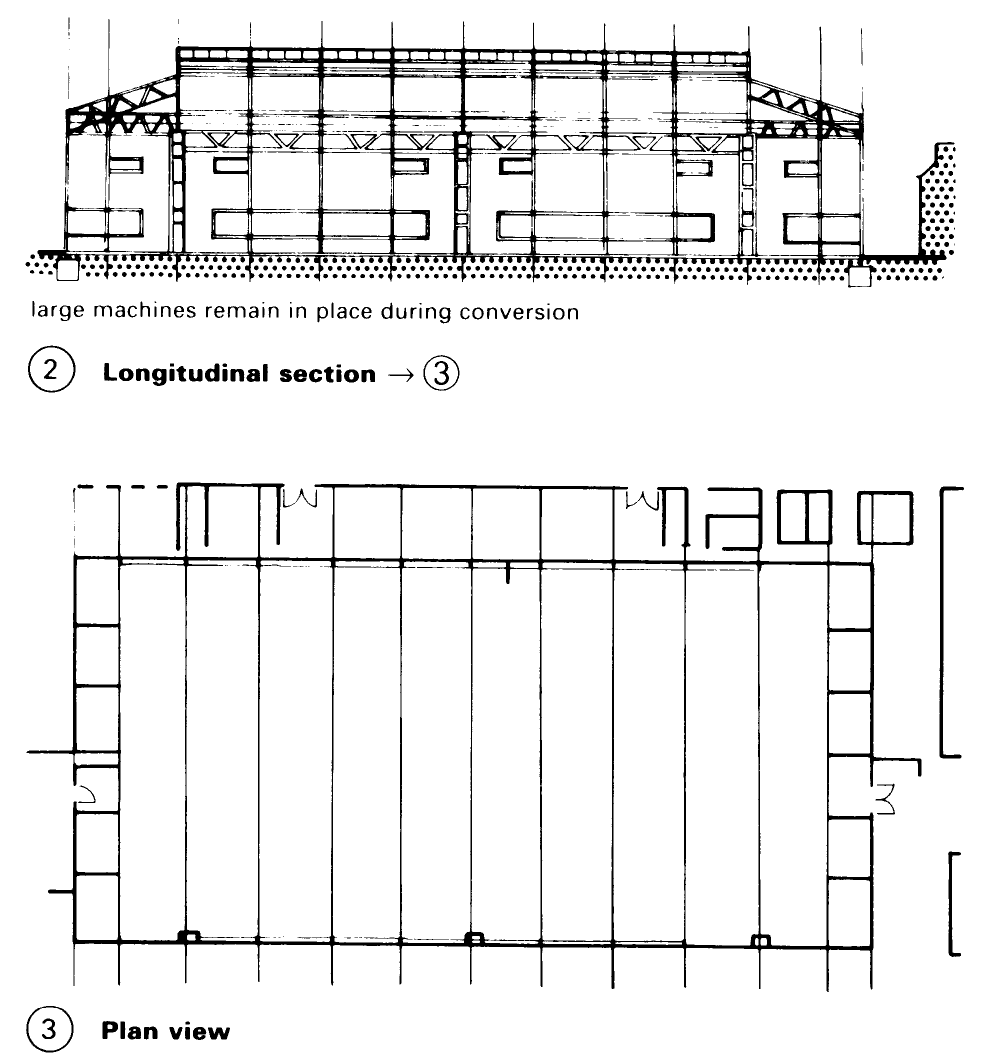

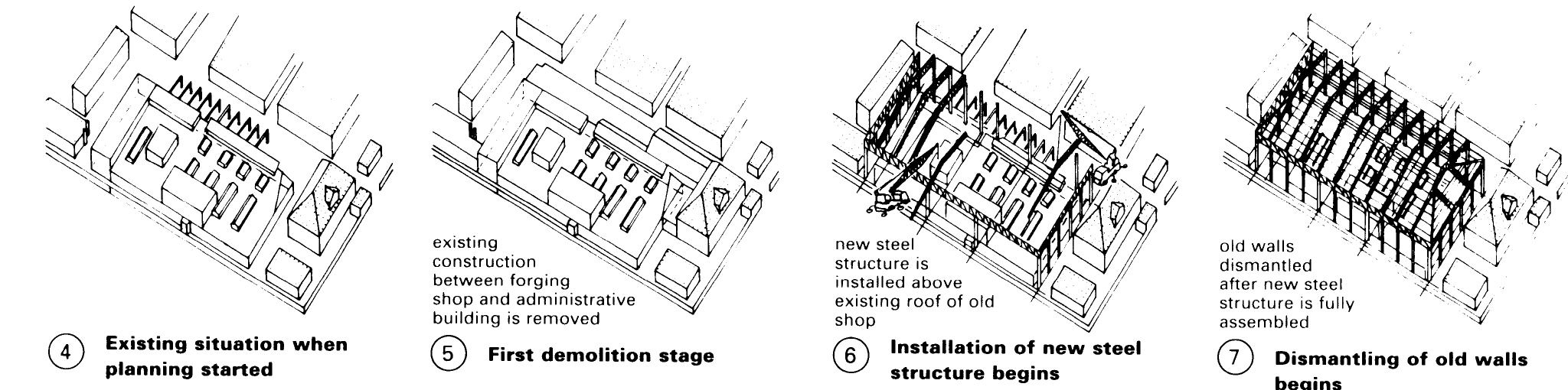

In this example a renewal and extension was carried out by building a steel frame over the top of an existing building. On densely built-up land in Munich a light metal works had reached a stage at which it became necessary to renew and extend the forging shop. The old building had already been altered many times and with the installation of new machines had undergone many different roof reconstructions – (1) – (3).

The requirements for the new shop were that it should:

- have substantially greater headroom;

- stand within the building lines of the old shop, because there was no possibility of pulling it down and rebuilding;

- not interrupt production for more than 2-3 weeks and keep disruption to the minimum;

- have an aesthetically attractive appearance that is in keeping with the adjacent listed administrative building;

- permit the addition of a second building phase.

Solution. The architects selected a steel structure to take advantage of:

- a column-free building - (2) + (3);

- a large span with low dead weight

- opportunities for prefabrication and assembly in a short time with lightweight equipment, a decisive factor in the project.

The outer walls consist of suspended concrete- composite prefabricated panels. These provide the high noise insulation mass and robustness required for a forging shop as well as permitting dry assembly.

Conversion work was precisely planned: after assembly of the steel structure the old shell was dismantled with a new, in-house overhead travelling crane and at the same time the new roof covering was progressively fitted – (4) – (8).

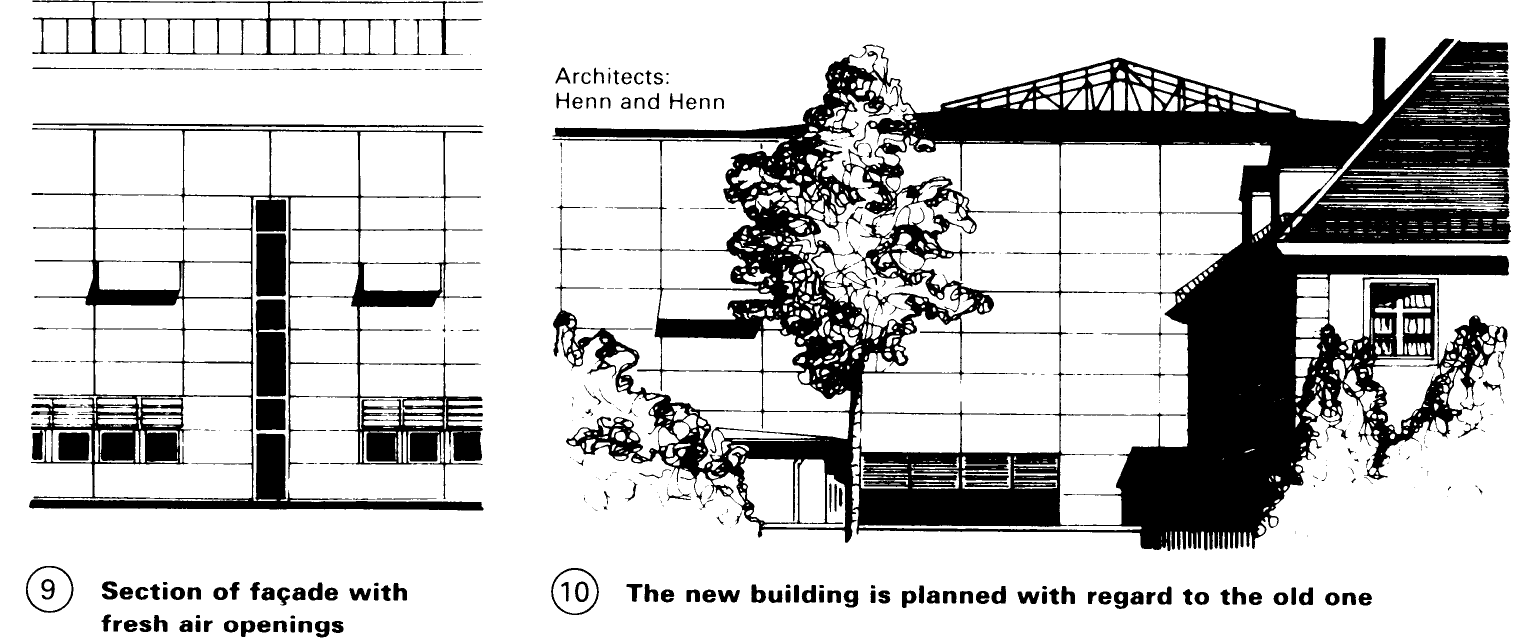

The sloping roof with trussed rafters is hipped at one end of the building in order to match the hipped roof of the administrative building, to maintain the spacing heights and to permit natural ventilation. Air supply louvres are built into the outer walls and extract air openings are in the roof ridge – (9) – (10).

This example examines the refurbishment of the main platform hall of Cologne Central Station. All corrosion and residual war damage was to be removed from the beautiful 80-year-old steel structure, which has 30 main curved trusses. The multilayered roof skin and strip rooflights also had to be renewed. The historical shape had to be retained, despite the use of modern materials, and the building work could not significantly affect railway operations and traffic.

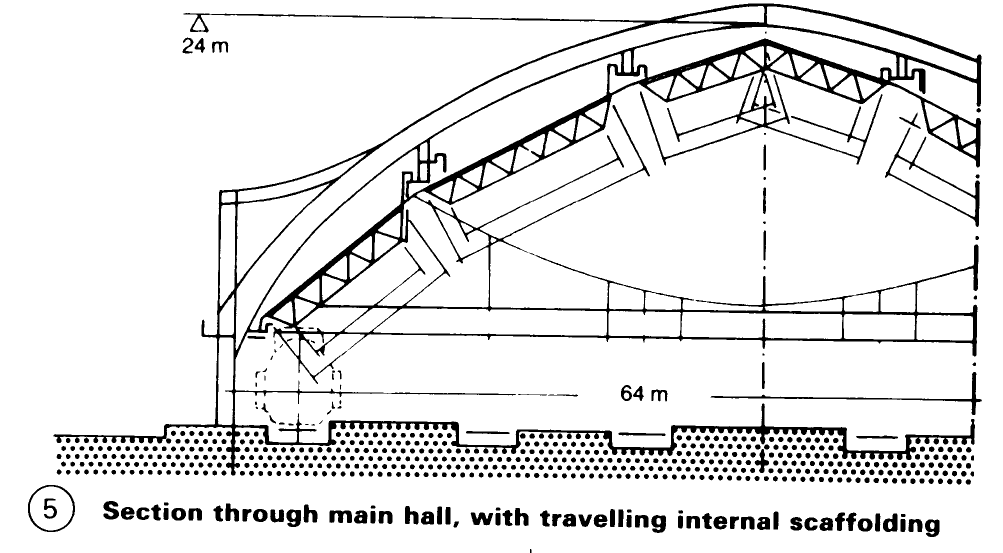

Solution. A travelling steel internal scaffolding unit was planned to give simultaneously a working platform and protect the railway operations below from falling tools or building components. It used the MERO nodal rod system, with 1400 nodes and 5000 rods, and consisted of five main components that were connected together to make one 50tonne element of 38 m x 56 m. It was moved in sections on six tracks and in three-weekly cycles. The individual parts, which were pre-assembled in a goods yard, were mounted on wagons and put together under the main hall arch according to a time plan that had to be accurate to the minute – (5).

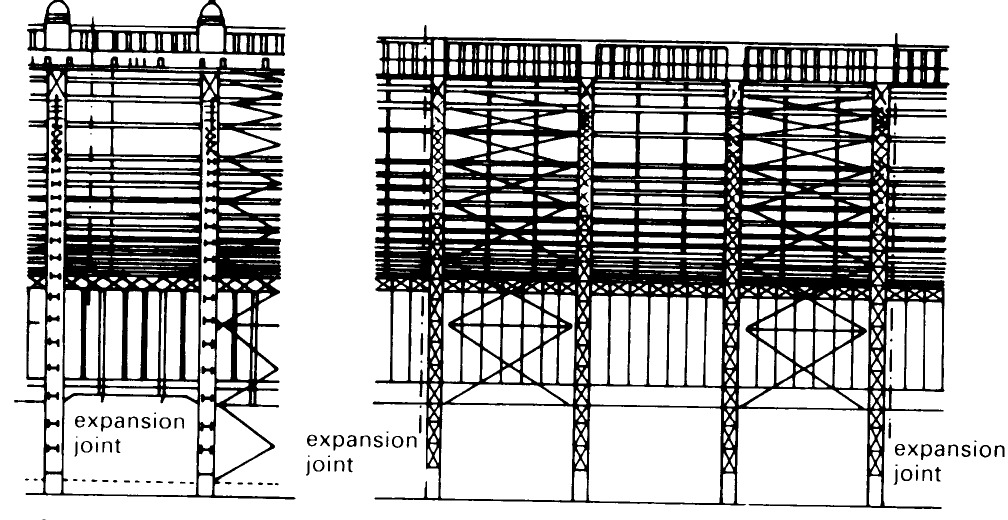

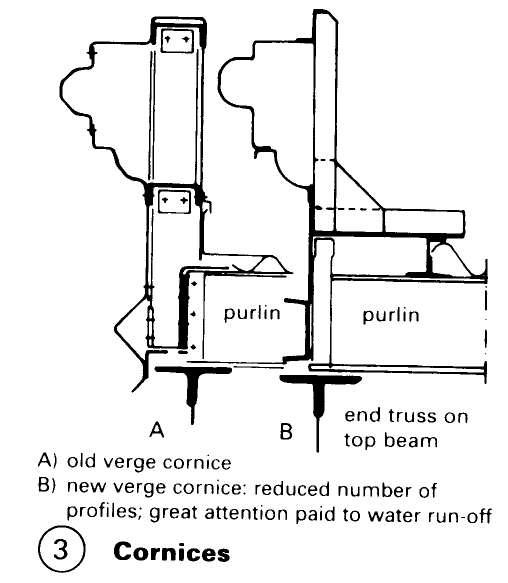

An illustration of how new technology was used in the restoration work is shown in the renewal of the transverse wind bracing. The old system connected two curved trusses respectively into one rigid unit and the round steel wind bracing extended right down to the luggage platform. In the new system, four curved trusses are respectively combined in the lower area to make a flexurally rigid frame and the expansion joints reduced – (4). Although the cornice details etc. have a lower number of profiles, they have also been designed to look almost identical to the old ones – (3).

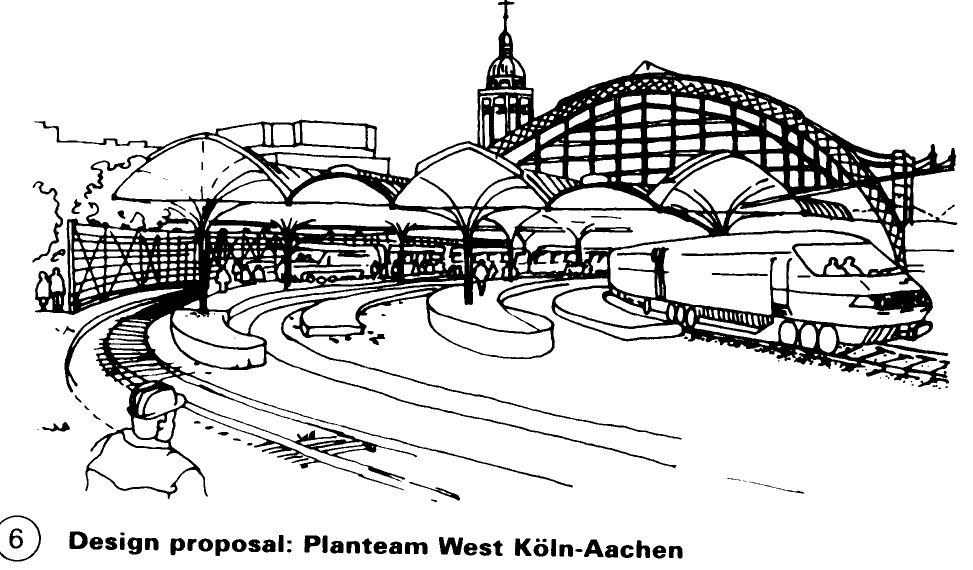

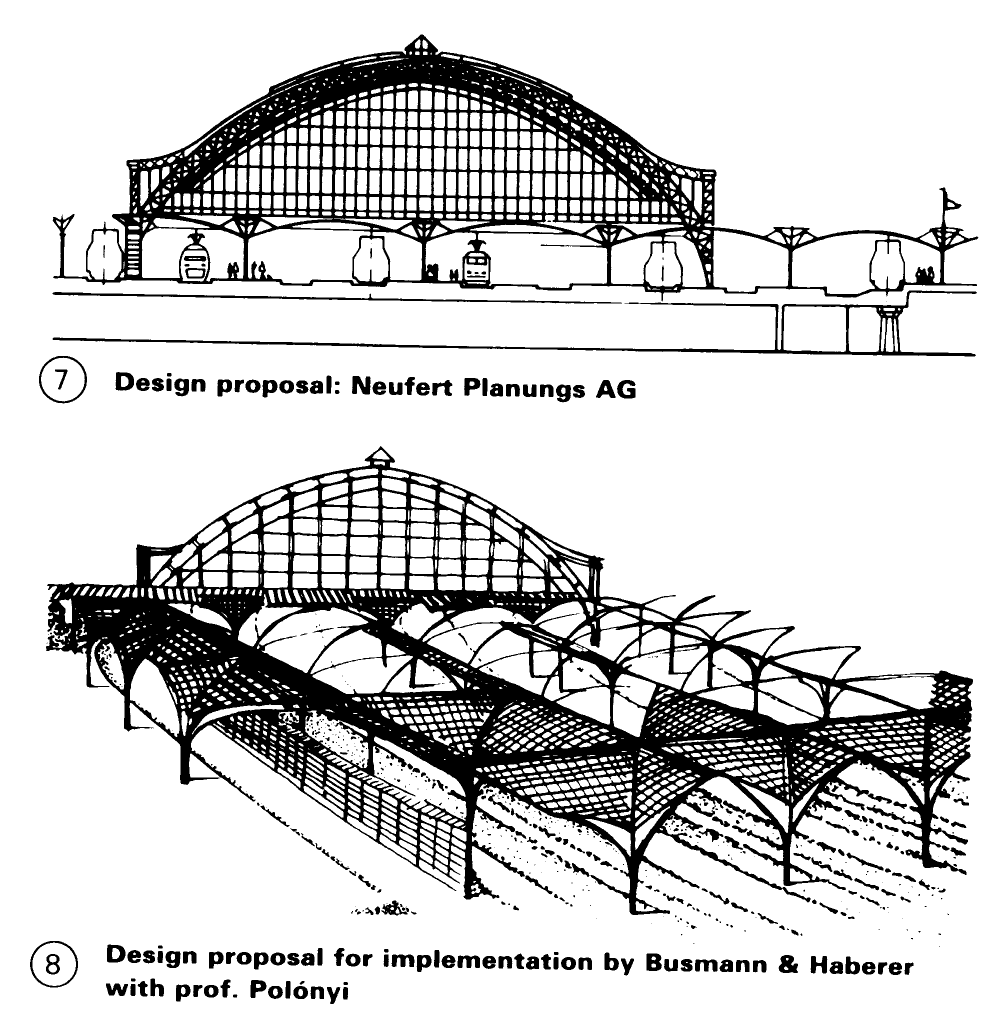

Following completion of the restoration of the main hall it was planned to renew the vaulted roofs to the south east. Being close to the cathedral and a new museum, the requirements went far beyond simple functionalism and the awkward geometry of the tracks added further difficulty. Three proposals were made during an expert survey – (6) – (8). Two used intermediately suspended and differently curved shell construction. The third proposed a spatially effective bearer system, which spans the whole area, like crossed vaulting - (8). Because this system offered considerable advantages it was recommended for further development.

Date added: 2023-01-05; views: 631;