Electroplated Overlays. Sputtered Overlay

These overlays are, from the alloy technology viewpoint, similar to the cast babbit metals but exhibit less hardness and a finer structure since they are precipitated out at temperatures below the melting point, sort of in a “frozen” state (see Fig. 7-270 below, three-material bearing). They are very insensitive to mixed lubrication but also wear very quickly because of their low hardness level, from 14 to 22 HV.

The most widespread is the PbSn(8-18)Cu(0-8) system, where the share of tin reduces corrosion sensitivity and the copper increases durability. Tin content in excess of 16% leads to faster diffusion and thus to long-term instability, while more than 6% copper can cause brittleness so that the strength-enhancing effect is negated. PbSn has a certain degree of significance in the Anglo-Saxon regions as does SnSb7 for bearings in large industrial engines, without their having made any widespread breakthrough.

These layers are applied in galvanic baths with the application of current. This is done in a four-stage process encompassing pretreatment, applying and activating the intermediate layer, precipitating the overlay, and using subsequent heat treatment to stabilize the structure and to induce a sufficient diffusion bond.

Overlay thickness is limited for several reasons:

- Durability drops rapidly with increasing thickness.

- The geometry of the lubrication gap must not change unacceptably as a result of wear.

- A concentration of electrical voltages causes the layers to be thicker at comers and edges.

For economic reasons, too, mass electroplating is to be targeted if at all possible.

As a rule, overlays of from 15 to 35 μm thick are applied in mass electroplating processes; where thicker layers are necessary—in large bearings, for instance—they have to be reworked retroactively.

Sputtered Overlay. A development that has made considerable advances in mass production only in recent decades is the use of the sputter process to deposit AlSn layers on plain bearings.

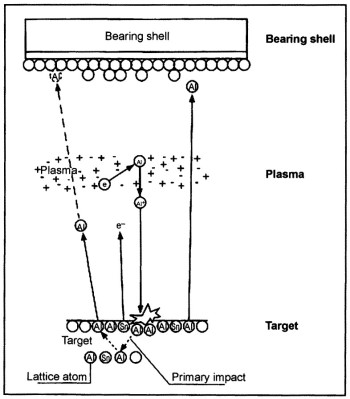

Sputtering (cathode ionization) is a coating process in which a working gas (argon) is ionized in a high vacuum. An electrical field accelerates the ions to the cathode, the “target,” and atoms are dislodged from the target by the impact of the atoms. These atoms condense on the bearing running surface and form the slip-promoting film, Fig. 7-267.

Fig. 7-267. Sputter process, schematic

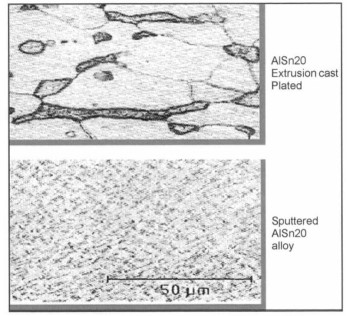

Atomic deposition creates a strong structure with an extremely fine distribution of the soft phase, which, in spite of high hardness at about 90 HB, gives good running properties (Fig. 7-268).

Fig. 7-268. Comparison of structures for roll bonded and sputtered AlSn20 layers

A further advantage of the process is the increase in bonding strength achieved by precleaning the substrate by sputter etching under vacuum, producing a highly active surface.

Today AlSn20Cu is used almost exclusively as the sputter layer for heavy-duty bearings, but the process is, in principle, quite flexible and enables deposition of a very much broader range of alloys than is possible with conventional electrochemical processes. The only major drawback is the high cost for the coating.

Date added: 2024-07-30; views: 429;