Bearing Materials. Bearing Metals

In addition to its primary function, transferring load during relative motions, the bearing has the additional important task of concentrating any disturbances in the system upon itself. The engine block, the crankshaft, and the con- rod should be protected for as long as possible from any consequences of a fault in the system.

Bearing metals are thus constructed so that they can absorb the adverse consequences of mixed friction largely without damage to themselves or to adjacent components. As a rule, they are made up of a harder matrix (e.g., CuSn, AlCu) into which are embedded the soft, immiscible phases that melt at lower temperatures (primarily Pb, Sn). This produces an error-tolerant alloy with good heat transfer properties, a low coefficient of friction, and a reduced tendency to weld to the steel.

Every good bearing material is a compromise between the contradictory requirements for strength and good tribologic properties. The best composition takes account of the weighting for the particular application.

In spite of the multitude of different but in some cases very similar materials made by various bearing manufacturers, one may categorize those that are most important for use in internal combustion engines in three groups of bearing metals and two groups of overlays (Fig. 7-262).

Fig. 7-262. The most important bearing metals for composite bearings

Bearing Metals. Babbit Metals. Steel and babbit metals are currently found only (on rare occasions) in passenger car engine designs, in bearings that are subjected only to low loads (camshaft bearings, sprockets). The SnSb8Cu and PbSn8 alloys have superb running properties, but their long-term strength is insufficient to handle the pulsating loads occurring in the drive train in modem engines.

The composite material incorporating steel is manufactured in stationary sand casting or centrifugal casting for thick-walled bearings and in strip casting for thin- walled bearings of smaller dimensions.

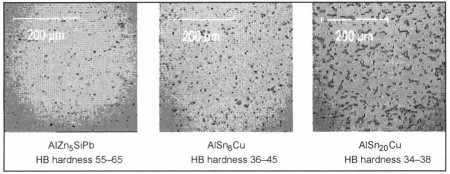

Aluminum Alloys (Fig. 7-263). Alloys based on aluminum have proven their utility as main bearings and camshaft bearings across a broad range of applications. When used as a two-material bearing without an overlay, they represent a very economical solution for moderate loads; as a three-material bearing and grooved bearing, they are in direct competition with leaded bronze compounds.

Fig. 7-263. Comparison of microstructures for Al bearing alloys

Aluminum alloys are not suited, as per today’s standards, for heavily loaded bushings where a slewing motion is encountered, e.g., in the small conrod end and the rocker arm; neither do they provide a satisfactory basis for sputter bearings.

AlSn alloys are the ones most frequently used. Upwards of about 15% tin content, these alloys exhibit good slip characteristics; their excellent corrosion resistance makes it possible above all to use them in gas-fired engines and large four-cycle engines fired with heavy oil. Both AlSiSn materials and AlPb alloys are used in the Anglo-Saxon regions and in Japan.

AlZn4 and 5SiPb are used when dealing with heavy loads such as those found in conrod bearings. This material does not have an embedded soft phase and thus is suitable for use as the substrate for three-material or grooved bearings only when an overlay is applied.

The manufacture of aluminum bearing alloys is affected in a continuous or semicontinuous casting process; the process windows are limited by the formation of separations (liquidation) in the soft phase and by the appearance of fissures in the hard phase. The stronger the matrix and the higher the tin content, the narrower the processing window.

The method used most widely today is horizontal extrusion casting, which is noncritical for AlSn materials but which, however, cannot produce any higher-strength microstructures. A somewhat more homogenous structure can be achieved with vertical extrusion casting although the process is more sensitive to interference since the cooling conditions are more difficult to control.

Belt casting, the newest technological development, permits a broader bandwidth in the process and, beyond that, the combination of a high share of matrix strengthening elements and higher soft phase content. Since here the ingot—in contrast to the other two processes—is actually a belt that runs simultaneously, the chilling and solidification parameters are better tuned to suit the particular material composition.

After casting, the strips are rolled out in several steps and heat treated; AlSn alloys are then joined with a thin aluminum bonding layer and, depending on the thickness of the finished bearing, are wound into coils or stored as strips.

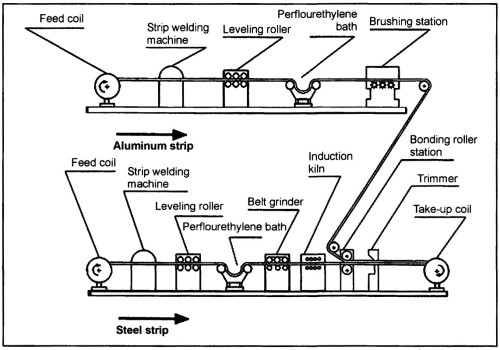

The join with the steel is made by roll bonding, which is essentially a friction welding process (Fig. 7-264). The surfaces of the two strips are cleaned and activated; they are heated and rolled together, then they are rolled down by 20% to 35%. The finished strip is then coiled up again. In smaller batches, plating is more economical in strips that are several meters in length; the process is essentially the same.

Fig. 7-264. Making the steel and aluminum bonded material

The newer AlSn alloys are also roll bonded with alloyed intermediate layers such as AlZn so that their higher strength can also be utilized in the composite.

Copper Alloys. The copper-based materials used for bearings are many and varied. CuPbSn type alloys are used almost exclusively for composite materials. Other alloys such as CuAl or CuZn are used as solid materials only in special cases.

Leaded bronze comprises a fixed CuSn matrix in which the lead is embedded. From 1% to 10% tin and from 10% to 30% lead is alloyed in. The higher the tin content, the stronger the material. The higher the lead content, the better the slip properties.

Two groups are formed:

- CuPb(18-23)Sn(1-3) for higher slip speeds as found in conrod bearings and main bearings and

- CuPb(10-15)Sn(7-10) for rocking movements as found in rocker arms and wrist pin bushings

In rotating applications, leaded bronzes are suitable only with an additional electroplated or sputtered overlay. Wristpin and rocker arm bushings may be used with or without an overlay, the choice depending on their size.

A major disadvantage of leaded bronze is lead’s sensitivity to corrosive attack by sulfur and chlorine compounds. Consequently, aluminum alloys are given preference when running with heavy oil and in gas-fired engines.

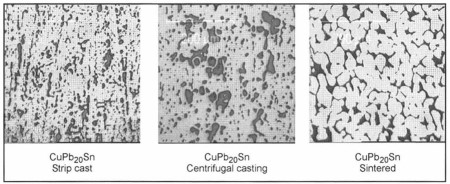

The bronze/steel composite material is made by casting or sintering.

Strip casting is a suitable process for composite material of up to about 6 mm thick; centrifugal casting is used for thicker bearings.

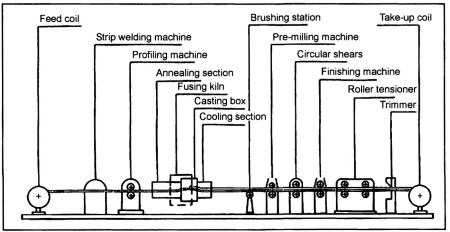

In the strip casting process used most widely for passenger car bearings, the edges of the pretreated lead strip are bent upward and the molten metal is cast into the “trough” thus formed. After cooling, the surface is milled down and the edges are trimmed. Stretching the strip slightly during these last two steps ensures stable steel strength. An optional, subsequent rolling step boosts the strength of both the steel and the bronze in heavy-duty bearings (sputter bearings). The strip is coiled up again for intermediate storage (Fig. 7-265).

Fig. 7-265. Making up the leaded bronze composite material in strip casting

When sintering, the sheet metal strip is pretreated, and then bronze powder is spread over it. The sintering process proper (sintering and rolling) is carried out in two steps in order to achieve a structure with only a very few, very small pores.

The microstructures differ markedly (Fig. 7-266) and the strength of cast bronze is, without having to take any additional steps, greater than that of sintered bronze.

Fig. 7-266. Structures of the CuPb20Sn2 alloy made up in various manufacturing processes

Overlays. Overlays have to be applied to all higher-strength bearing materials in order to achieve running properties of adequate quality and insensitivity to disturbances. Basically there are two fundamentally different types of coatings:

- Babbit metals deposited electrochemically

- AlSn alloys applied with the PVD (physical vapor deposition or sputter) process.

Surface modifications such as zinc phosphating are found in certain application niches but have not made a broad breakthrough.

An intermediate layer is required to ensure good bonding with the substrate and/or to suppress diffusion effects; nickel or NiSn is normally used for this purpose.

Nickel is not a material that offers good slip properties; consequently, the thickness of this layer should be considerably less than the surface roughness. Common are from 1 to 3 μm as otherwise larger, contiguous Ni areas appear on the running surface, and the bearing responds aggressively to disturbances where the overlay is worn.

Date added: 2024-07-30; views: 426;