Bearings in Internal Combustion Engines

The shafts found in multicylinder reciprocating engines— the crankshaft, valve train, and balancers—generally run in plain (sliding or friction) bearings.

The reasons for selecting this type include their great ability to withstand shock and their damping properties, easy division for assembly around the crankshaft or camshaft, low space requirements, insensitivity to grime, and, last but not least, the low costs when compared with rolling bearings. The fundamental disadvantage of plain bearings compared to rolling bearings is the higher friction level and the resulting greater oil requirements.

Rolling bearings are employed in engines in some cases wherever the advantages of the plain bearing are not fully exploited: At the crankshaft for small, singlecylinder engines, at the bearings for the sprocket drive, and, to an increasing extent, at the valve train (roller tappets).

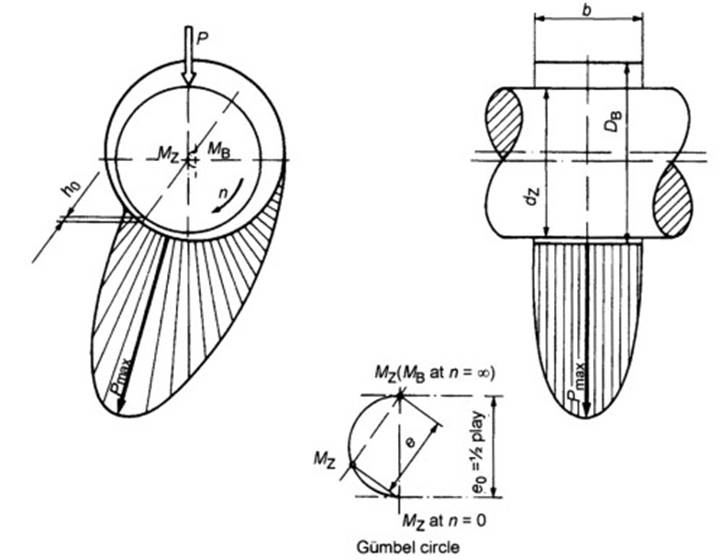

Fundamentals. Radial Bearing Constant Loading. The lubricant is drawn into a plain, radial bearing by adhesion, filling the lubrication gap between the surfaces that move relative onto the other; this causes a buildup of pressure that keeps external forces in balance and that keeps the mating components—journal and bearing—separated by an oil film, Fig. 7-252.

Fig. 7-252. Buildup of hydrodynamic pressure as a result of rotation

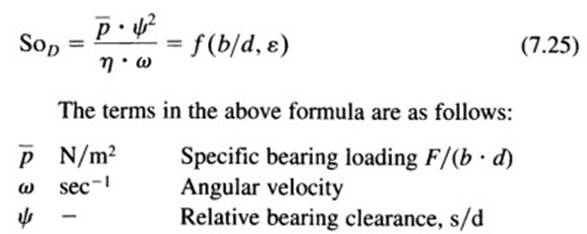

The dimensionless Sommerfeld number describes the interrelationships in a cylindrical radial bearing.

Dynamic Loading. A characteristic feature for the bearings used in engines is loading, which alternates periodically in both magnitude and direction; this results, for example, from the ignition and inertial forces at the crankshaft and from the pulsating loads resulting from the camshaft’s actuating the valves.

The change in force causes an imbalance that causes the shaft’s centerline to shift in the radial and circumferential directions. This eccentricity rises with rising loads; resistance to the displacement of the lubricant damps the radial motion. The high shock resistance of the plain bearing is the result.

The resultant additional bearing capacity is defined by the Sommerfeld number for lubricant displacement:

Fig. 7-253. Buildup of hydrodynamic pressure due to rotation and displacement

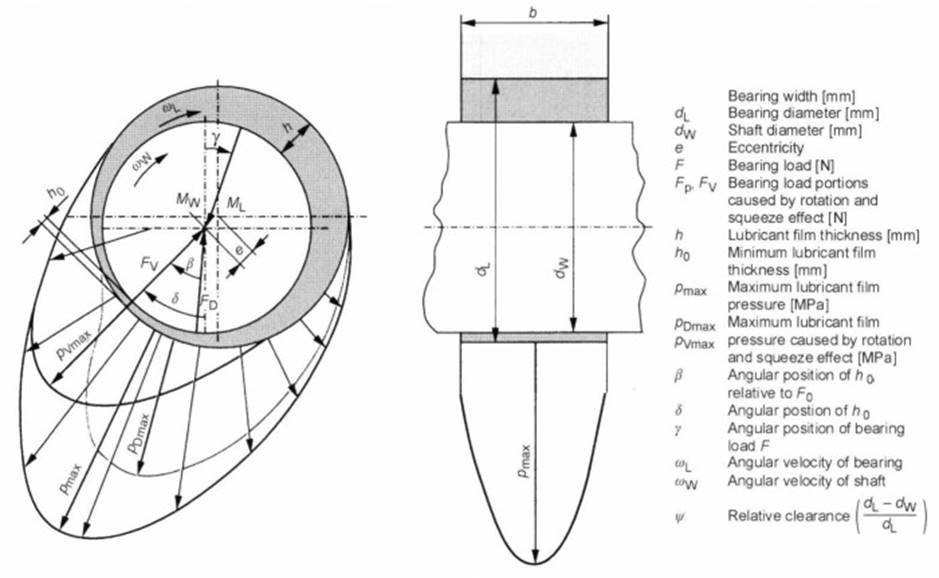

Friction. If a continuous and complete separation of the sliding surfaces were to be achieved by the oil film, then no bearing material would be required; the bearing would run entirely in accordance with hydrodynamic principles. Friction, in this case, is determined only by the oil’s shear strength and is very low, on an order of magnitude of μ = 0.002 — 0.005.

In real-world operations, however, there is contact between the mating surfaces since the bearing cannot form a sufficient hydrodynamic lubricating film for every operational state. This “mixed lubrication” situation is associated with far greater friction levels, increasing by as much as a factor of ten. The familiar, generalized Stribeck curve describes the interactions (Fig. 7-254).

Fig. 7-254. Stribeck curve

The system becomes thermally unstable if the friction energy thus generated cannot be dissipated. The probability that a thermally unstable situation is reached in a plain bearing, i.e., the susceptibility of the bearing to malfunctions, is dependent on the energy density in the bearing system (load, velocity).

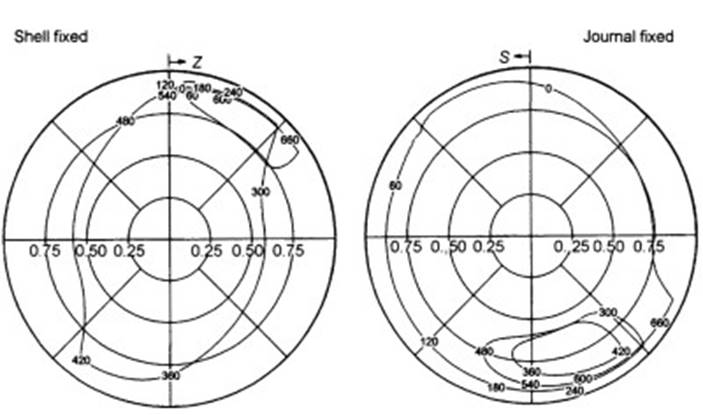

Following dynamic loading, the shaft centerline describes periodically within the bearing a certain displacement path (see also Fig. 7-257 below) with the smallest lubrication gap changing in size and location.

Fig. 7-257. Displacement path for a conrod bearing (viewed relatively from the bearing and the journal)

The results are, on the one hand, that a far higher degree of direct material contact can be handled and that the dimensions of the bearing can be far smaller than one that is under constant loading; on the other hand, every area is subject to pulsation loading and the material’s endurance becomes an issue.

Date added: 2024-05-31; views: 691;