Combustion Chamber and Port Design

The geometry of the combustion chamber is of major significance in cylinder head engineering. Technical calculations for this purpose are carried out simultaneously during the early development phase, which is why, before finalizing the concept, the geometries to be developed for the combustion chamber variants are determined. In coordination with the portion of the combustion chamber volume accounted for by the bowl at the top of the piston, extensive basic examinations are performed.

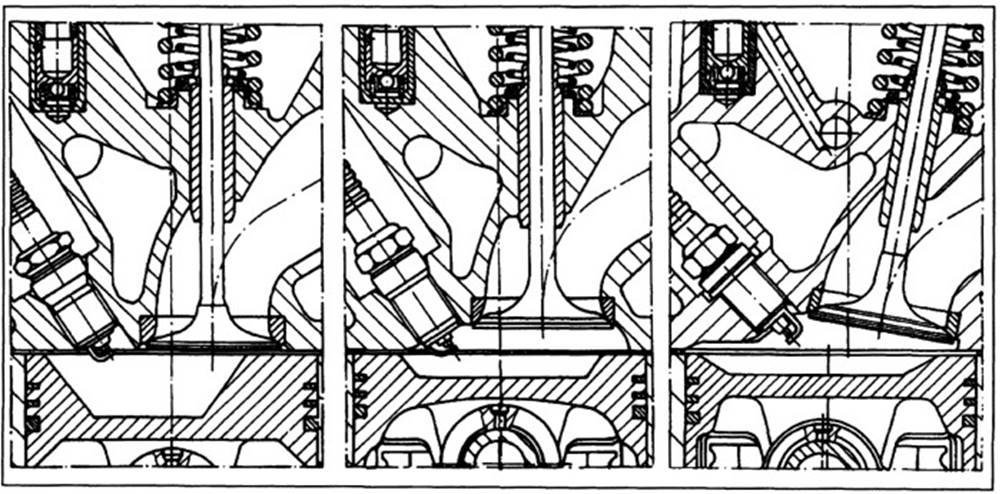

Concepts such as charge stratification in direct-injection gasoline engines are assessed in conjunction with the port and combustion chamber geometries and are tested on real- world models. Three examples for the development of a two-valve concept with various combustion chamber designs are shown in Fig. 7-72.

Fig. 7-72. Combustion chamber variants for a two-valve cylinder head

The rough geometry of the combustion chamber is also determined by the variation of the valve angle. In this example, in the interest of better comparison, the same cam follower design was used for all three embodiments. Among the matters examined was the extent to which the charge volume available burned most favorably. The overall influence becomes clear in specific consumption values, the amenability to leaning out the mix, and, in particular, the raw NOx and hydrocarbon emissions in the exhaust gases.

The situation shown in the right-hand depiction proved to be advantageous. The spark plug, extending well into the combustion chamber, is arranged so that it is fully surrounded by the mix drawn into the combustion chamber. In the design selected here, about 70% of the combustion chamber volume is inside the cylinder head and 30% is in the piston.

The interdependencies described here between combustion chamber geometry and the effects on the engine are to be found again in direct-injection gasoline engines currently under development where fully variable valve control is used. The development effort required there is considerable. The parameter studies to be defined for combustion chamber trials demand a great deal of experience and development discipline by the thermodynamics engineers.

Four-valve cylinder heads with the spark plug at the center offer the fundamental advantage of short combustion paths in the combustion chamber. Because of the valve head’s large share of the total surface that defines the combustion chamber, the casting contour has only a slight influence on the volumetric tolerances, which can be kept very narrow at, in one example, 0.5 cm3.

To reduce thermodynamic losses during combustion, one strives to achieve the lowest possible ratio of combustion chamber surface area to combustion chamber volume. One key thrust in development is optimizing the geometry of the squish surface. Here the location varies in relationship to the valves, shape, and size.

An excessive share of squish area has proved to be detrimental because of the increase of the surface-to-volume ratio and the associated heat losses. Using the example of the four-cylinder engine shown here, a squish surface share of 7% proved to be favorable. In modem, four-cylinder engines with external fuel mix blending, the trend is toward flat piston heads with the bulk of the combustion chamber located inside the cylinder head.

With the development of new ignition concepts such as direct-injection gasoline and diesel engines, the development of the ports has become a science in itself. Attaining specific, reproducible charge flow is the subject of many basic research projects that are taking place parallel to overall cylinder head development. The design of the port has to be seen in conjunction with the designs for the intake and exhaust manifolds.

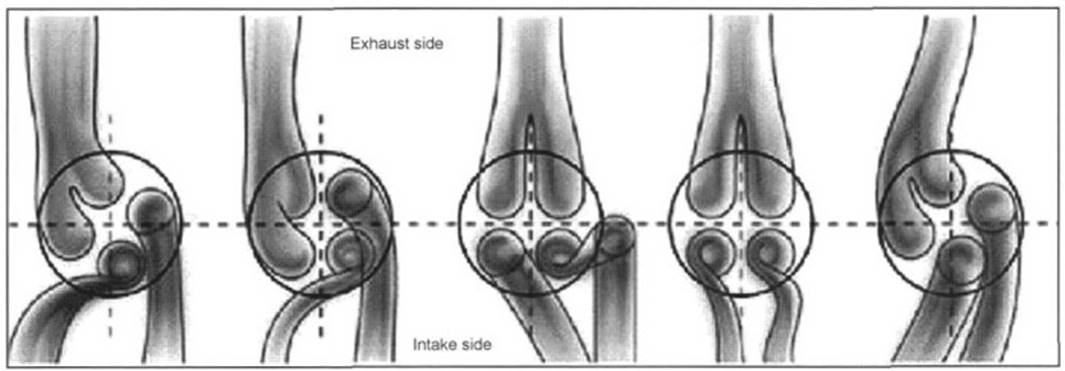

This topic is dealt with primarily through trials and flow simulations. Here the engineer pays attention to finalizing these geometries early in the work since changes at the port can often trigger major changes in the cylinder head. Often so many thermodynamic interactions occur while defining the geometries for ports and combustion chambers that it is difficult to estimate how much time engineering will take. Potential port arrangements for a direct-injection diesel engine are shown in Fig. 7-73.

Fig. 7-73. Intake and exhaust valve variations for a four-valve diesel engine

In diesel engines, swirl is imposed on the incoming air in order to intensify blending of the fuel and air mixture. There are two basic options for intake port design that may be drawn upon here:

- Helical (swirl or helical port)

- Sloped port configuration (tangential port)

In selecting the shape for the port, one pursues the objective of achieving the required swirl characteristic and the best possible flow throughput. This effect is to be preserved to mass production. In the swirl port shape, the port imparts the swirling motion on the incoming air. This results in smaller swirl deviation at relatively less favorable flow throughput values. In the tangential design, in contrast to the above, the incoming air is set in rotation by the cylinder wall, because of the port’s off-center location.

Typical here are high throughputs at good cylinder fill. Combining a swirl chamber with a downstream tangential port is thus a very good compromise in the conflict of goals between throughput and swirl stability.

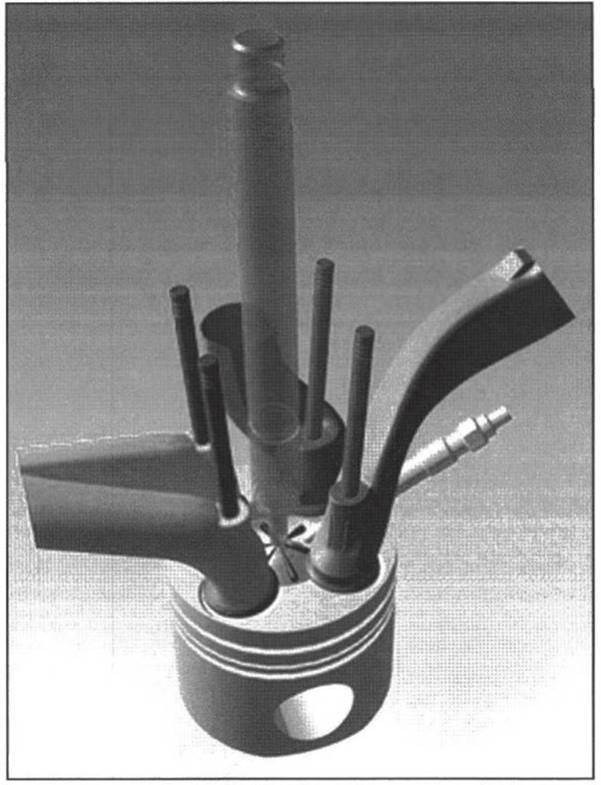

Fig. 7-74. Arrangement of the gas exchange ports in the cylinder head

The “helical port design, oriented vertically from the top to the combustion chamber,” as shown in Fig. 7-74, improves port quality when compared with an arrangement at the side. Additionally, the glow plugs can be situated on the colder side of the cylinder head, where the thermal load is less. The short run for the exhaust port inside the cylinder head keeps heating to a minimum. The port configuration described here makes a symmetrical valve arrangement with beneficial effects on the location of the valve train possible, Fig. 7-74.

Date added: 2024-04-24; views: 622;