Engineering in Construction Steps. Using CAD in Engineering

It is impossible to predict all the influences that will be encountered while engineering the cylinder head, particularly when new combustion processes are being developed. Computer assistance in the basic design or the calculation processes used in simulation technologies do, indeed, help to generate a great deal of information in advance.

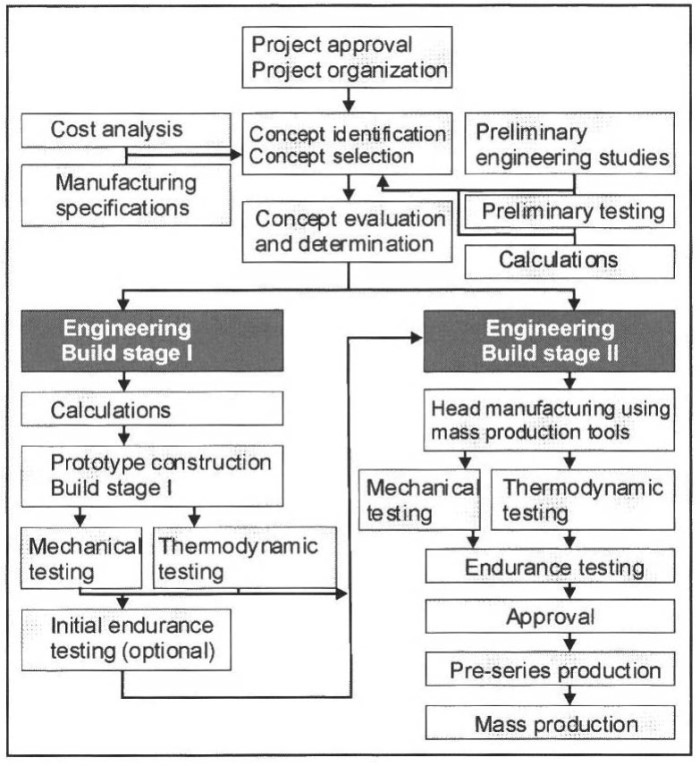

The mutually influencing factors on cylinder head development are very complex, however, so that there is much to be said for using several construction stages in cylinder head development. Moreover, testing the engine’s thermodynamic and mechanical properties delivers many findings that also cannot be predicted in advance (Fig. 7-76).

Fig. 7-76. Example of development steps for cylinder heads in two construction steps

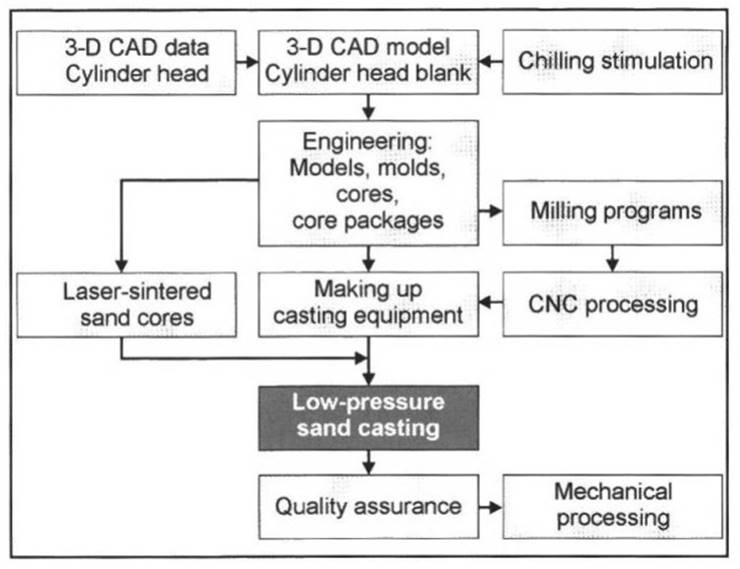

Fig. 7-77. Example of a flowchart for making up cylinder head prototypes, after Becker

When developing entirely new cylinder head concepts, it may make good sense to obtain cylinder heads as prototypes—quickly and economically—for use in preliminary development. When building these prototypes, it is often advisable to use manufacturing techniques that differ from those used in mass production. Thus, small numbers of cylinder heads to be used as prototypes may be built in a low-pressure sand-casting process.

Figure 7-77 shows an example of the flowchart for fabricating cylinder head prototypes by this procedure. Smaller companies have specialized in this particular field and are able to deliver initial prototypes as quickly and economically as possible.

To reduce overall cylinder head development time, the goals to be met in any given construction stage must be defined exactly. The project management work required here is of vital importance. As a rule, the development of the second construction step is commenced while the first construction step is still being tested. Here the manufacturing processes foreseen for mass-production use should be employed. Particularly, the rough cylinder head casting should be made up using the casting process selected for volume production.

The development of a cylinder head to readiness for mass production in a single step is possible for designs based on existing heads and exhibiting only minor modifications.

Using CAD in Engineering. Because of the multiple uses of CAD data, cylinder heads are modeled in the CAD systems in complete, threedimensional renderings. The specifications for the model and the casting equipment can be derived from this data. The geometries can also be used for simulation calculations. When engineering a new cylinder head, interdependencies among its components can be parametrized; refer also to Section 8.5.2.1.

This makes it possible to carry out basic studies simply and quickly. Model builders and casting specialists should be consulted continuously during detailed engineering work, beginning as soon as the rough cylinder head concept has been finalized with the definition of the internal components and the major dimensions. In this way, manufacturing considerations are accounted for in the process early. Engineering methods vary, depending on which CAD system is used. It makes sense, for example, to limit parametrization of the cylinder head to a few parameters to maintain flexibility when changes are made to the model.

All the engineers involved in the project should use identical software with identical default settings. Because of the complexity of the CAD methods, one person on the development team should be responsible for adherence to the methods. Since the cylinder head involves many interfaces to adjacent components, transfer conditions to these components have to be defined.

The consistency of the CAD process provides many advantages. Data become more reproducible, can be used more easily for series of cylinder heads, and largely preclude any inaccuracies between engineering and manufacturing. Cylinder head engineers who prepare the overall concept for a new component need a great deal of practical experience. Today the designs are generated completely using CAD.

Date added: 2024-04-24; views: 632;