Toothed V-Belt Drive to Power Auxiliary Units

Auxiliary units were driven in the past with simple V-belts. Because of the increased complexity triggered by owners’ increased demands in terms of comfort, integrating the alternator, water pump, power steering pump, and air conditioning compressor into this drive system is now state of the art.

The complexity of the drives is further increased by additional units such as the fan and mechanical turbochargers or pumps used for secondary air injection. Today the auxiliary units are driven in a serpentine configuration with multirib V-belts (Micro-V® belts). The major benefits that the Micro-V® belt offers when compared with V-belt drives are greater power transmission and reduced installation space in complex drives.

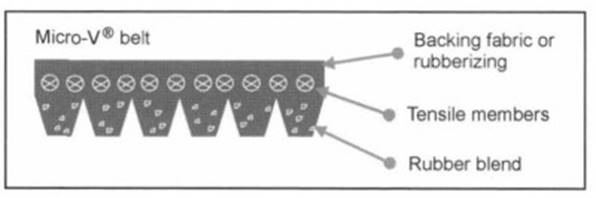

Micro-V® Drive Belts. Structure of the Micro-V® Belt. The Micro-V® belt is a bonded system made of three components (Fig. 7-246):

- Fiber-reinforced rubber blend

- Tensile cords

- Overcord or rubber backing

Fig. 7-246. Structure of the Micro-V® belt

The tensile cords transmit drive power from the crankshaft to the auxiliary units, absorb dynamic loads at low stretch, and provide good resistance to alternating flexure.

The cords are made of nylon, polyester, or aramid; the widely differing moduli of elasticity for the tensile cords enable optimized tuning of system dynamics. The rubber forms the V ribs and transfers the drive forces from the pulley into the tensile cords. Chloroprene or EPDM is used as the material; fiber material is added to the rubber blend to stiffen the product.

The overcord can either use a backing fabric or be made through rubberizing. During the manufacturing process, the cords in the tensile member are twisted, clockwise and counterclockwise in pairs, in order to achieve largely neutral running properties for the belt.

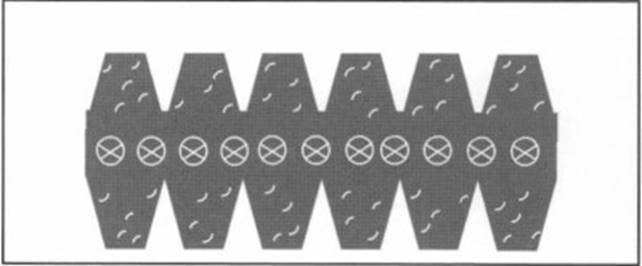

The Micro-V® belt is manufactured in a vulcanization process. The V ribs are either molded from the very outset or are cut into the belt after the vulcanization. In double-sided belts this grinding process is carried out on both sides.

Micro-V® Belt Profile. It is the PK profile (as per ISO standard) that is normally used for automotive applications. The groove spacing is 3.56 mm. The designation for the belt, such as 6 PK 1270, means six ribs, PK profile, 1270 mm reference length. When components that draw a great deal of power—such as the alternator, power steering pump, or air conditioning compressor—are driven with the back of the belt, the belt can also be designed as a double-sided Micro-V® belt, with ribs on both sides (Fig. 7-247).

Fig. 7-247. Double-sided Micro-V® belt

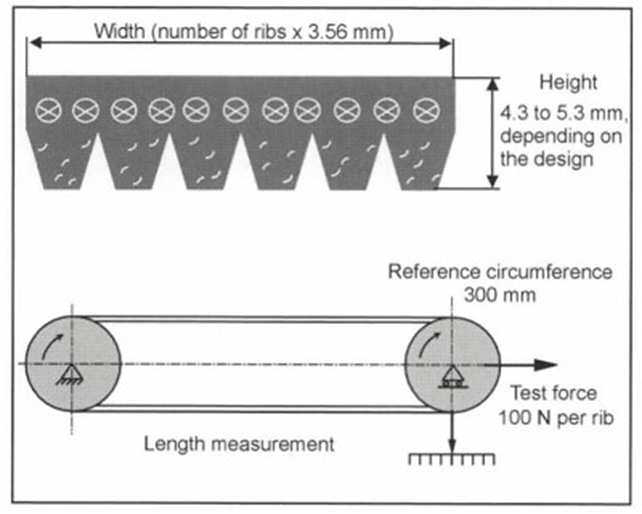

Characteristic Values for Micro-V® Belts and Sprockets. The most important key values for the Micro-V® belt are shown in Fig. 7-248. The belt width is calculated by multiplying the number of ribs by 3.56 mm (PK profile). Belt thickness, depending on the design, is between 4.3 and 5.3 mm. The reference belt length is determined on a two- pulley test bed at a defined preload (ISO 2790). The reference circumference of the pulleys used here is 300 mm.

Fig. 7-248. Characteristic values for the Micro-V® belt

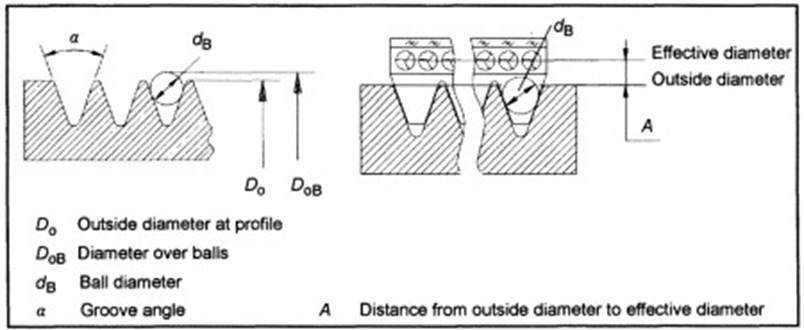

The standardized profile used for the pulleys is shown in Fig. 7-249. The outside diameter of the flanges is one dimension used to describe the pulley. More important for the design and determination of belt length, however, is the pulley diameter across the test balls (2.5 mm diam.). With this measurement technique, the profile of the pulley and thus the groove angle is also taken into account.

Fig. 7-249. Key values for Micro-V® belt pulleys

The groove angle is matched to the belt profile running (and deformed) in the wrap arc and deformed, dependent on the diameter of the pulley. Normal groove angles lie in a range of from 40° to 44°. The effective diameter is then calculated, in accordance with the belt design, using the diameter measured across the test balls.

The effective diameter is congruent with the center of the tensile cords in Micro-V® belts. Characteristic values for common belt designs are defined in DIN 7876 and ISO 9981. During detailed design work, however, it is necessary to draw upon the characteristic values published by the belt and/or pulley manufacturer. The pulleys are made of either steel or plastic.

Date added: 2024-05-31; views: 620;