Chain Drive and Designs

The primary function of the camshaft is to ensure that the valves open and close at the correct times. In modem overhead valve engines this is done by power transmission from the crankshaft. In most cases, toothed (synchronous) belts, or roller toothed (silent) or bushed roller chains of various weights are used. The selection of the design depends on the engine maker’s philosophy.

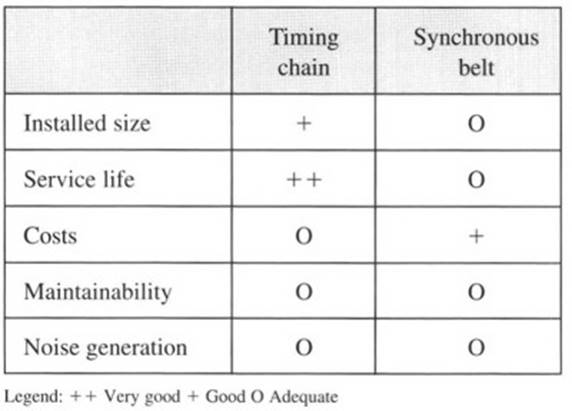

The most important criteria in the choice of drive concept are the costs, the amount of space occupied, maintainability, service life, and noise generation.

A comparative evaluation of a timing chain and synchronous timing belt is shown in Fig. 7-227.

Fig. 7-227. Comparative evaluation of timing chains and belts

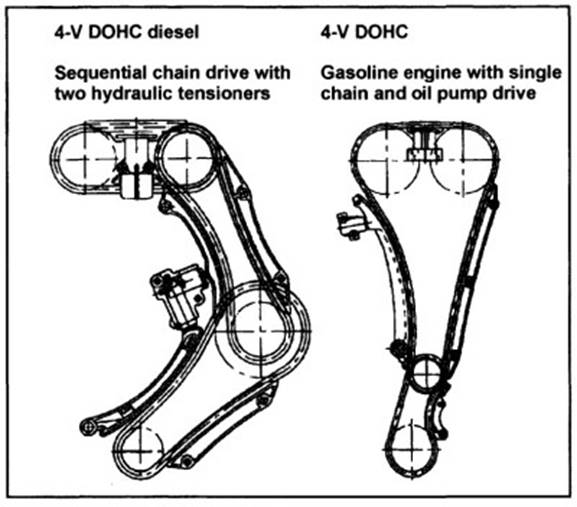

In modem engines, these power transmission systems often serve not only the camshaft, but other components such as the oil pump, water pump, and fuel injection pump as well. Figure 7-228 shows examples of potential arrangements.

Fig. 7-228. Timing chain drive

Since neither the camshaft nor the crankshaft runs entirely smoothly and since the power required by the injection pump is subject to severe, periodic fluctuations, this drive system is exposed to very complex dynamic loading.

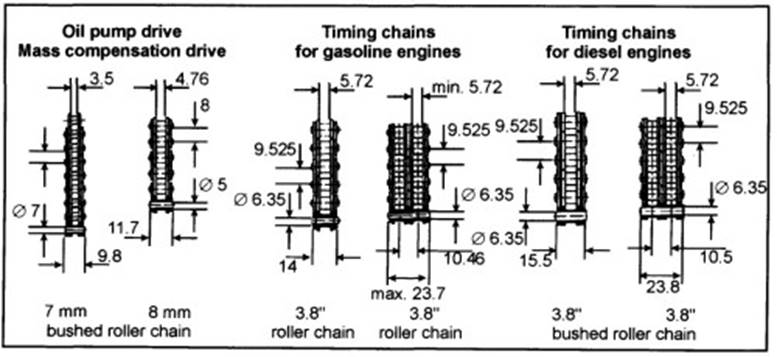

In the course of decades of experience, certain dimensions for the roller and bushed roller chains used in timing drives have proven to be particularly suitable.

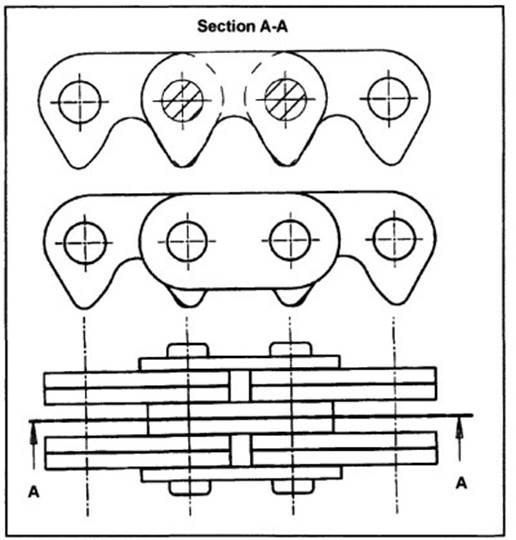

Chain Designs. Among the standard chains, one differentiates between roller and bushed roller chains. In addition, there are both simplex and duplex chains, Fig. 7-229. A special form of the chain is the toothed chain, Fig. 7-230, also referred to as a silent chain.

Fig. 7-229. Chain designs

Fig. 7-230. Silent chain

The plates in toothed chains are shaped so as to enable direct force transfer between the chain and the sprocket, while in roller and bushed roller chains the interface wit the sprocket takes place at the pivot joint via pins, bushes, or rollers. Silent chains can be made of any conceivable width without any fundamental change in design. Guide plates are provided to keep the chain from wandering off the sprocket; they may be located either at the center or on either of the outside edges.

The rollers, rotating over the bushes in a roller chain, encounter a small amount of friction when rolling along the sprocket’s teeth. Thus, the contact point at the circumference changes continuously. The lubricant between the rollers and the bushes contributes to noise and impact damping. In a bushed roller chain, by contrast, the fixed bushes always mate with sprocket teeth at the same point. Thus, perfect lubrication for such drives is particularly important.

At the same pitch and failure strength, a bushed roller chain exhibits a larger joint surface than corresponding roller chains. A larger joint surface causes lower pressures at this surface area and thus less wear.

Bushed roller chains have proven their value, particularly for heavily loaded camshaft drives in high-rpm diesel engines. Whenever the transfer of a given torque at a certain maximum sprocket diameter using a simplex chain requires a number of teeth greater than 18, it is advisable to go to a multiple chain with the same or smaller pitch.

Date added: 2024-05-31; views: 657;