Acoustics. Noise Creation. Optimization Measures

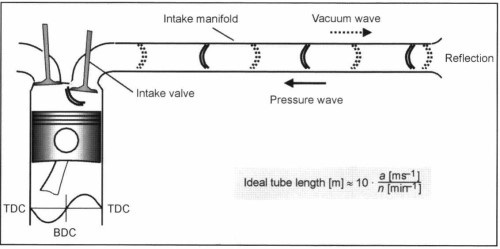

Sound is understood to be mechanical oscillations and waves in an elastic medium. Section 7.20.1 used Fig. 7-277 to illustrate how piston movement, after the intake valve was opened, triggered a vacuum wave moving against the gas flow direction. These pressure fluctuations are propagated as sound through the air filter intake opening (intake noise).

Moreover, the pulsation inside the components induces wall vibration (structural noise), which is then again propagated as airborne noise. Those in the vicinity do not always perceive this sound as pleasant, which is why restrictions have been imposed; every vehicle must meet these limits.

Fig. 2-277. Principle of resonance tube charging

Legislation. The noise problems associated with motor vehicles can be subdivided into two areas:

- Interior noises

- Pass-by noise

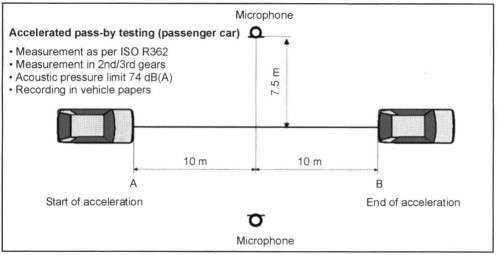

While the reduction of interior noise goes hand in hand with passengers’ increasing comfort expectations and thus is a factor in the make’s image, a legislated limit value applies to noises generated by vehicles accelerating past a given point. The procedure used to measure this value is illustrated in Fig. 7-281. Since October 1, 1995, passenger cars may not exceed a value of 74 dB (A) in accelerated pass-by testing.

Fig. 7-281. Motor vehicle noise

The overall acoustic level is the sum of just a few individual noise sources. Regarding pass-by noise, these are engine noise, intake and exhaust noise, tire noise, and wind noise.

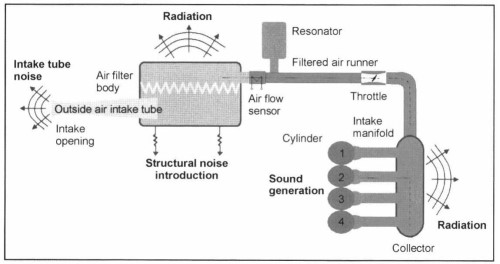

Noise Creation. In an internal combustion engine, the pistons, with their reciprocal motion, create fluctuations in air pressure (air pulsations) and airborne noise that results from them. The pistons thus act as an air-pulsation noise source. Disturbances in airflow along the intake system can also act as aerodynamic sources, contributing to intake noise.

Fig. 7-282. Noise sources in an intake system

This noise is emitted primarily through the intake opening and thus passes directly into the environment. A second portion of the pulsation energy inside the intake system incites structural noise oscillations in the elastic structure. These are then transmitted from the exterior surfaces to the surrounding air or through attachment points to the body. This situation is illustrated schematically in Fig. 7-282.

Optimization Measures. The objective of the measures undertaken to optimize intake noise is consistent acoustical development wherein the noise is to be reduced right from the draft stage. The work carried out to optimize noise is subdivided into primary efforts and secondary efforts.

Primary efforts: These exert an influence on the sound source. The noise created by airborne sound means a reduction in the alternating pressures, while the noises excited by structural sound require a reduction in the exciting forces and a change in structural noise behavior and in propagation (admittance and degree of propagation).

Secondary efforts: These retroactively reduce the airborne sound generated and reduce noise emissions with mufflers and/or encapsulation.

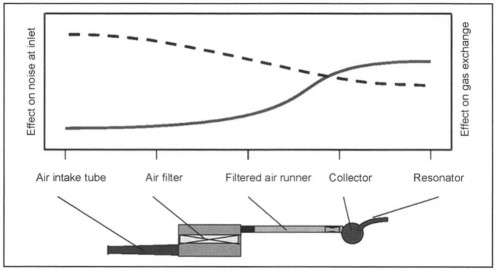

Fig. 7-283. Effect on the intake tube noise and gas exchange in the cylinders

The pulsed-air noise source in the intake system is the engine; any influence on this source often conflicts with the objectives set in the thermodynamics analysis. That is why one employs secondary measures such as damping filters and shunt resonators to reduce intake noise. The effect of acoustic corrections on the throat noise and on the gas exchange is shown in the example in Fig. 7-283.

Date added: 2024-07-30; views: 477;